Spring return type rope-driven mechanical arm

A mechanical arm and recovery technology, which is applied in the field of spring-returning rope-driven mechanical arms, can solve the problems of lower energy utilization, high power of the mechanical arm, and large mass of the boom part of the mechanical arm, so as to improve energy utilization. , Reduce power consumption, reduce power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

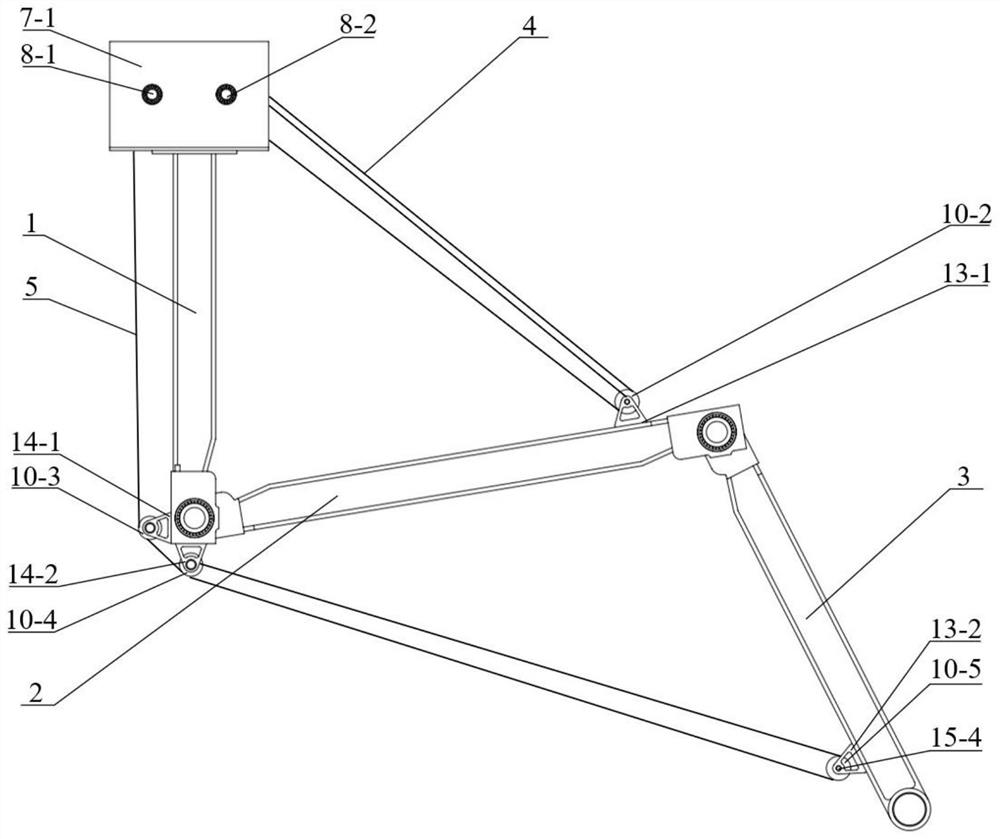

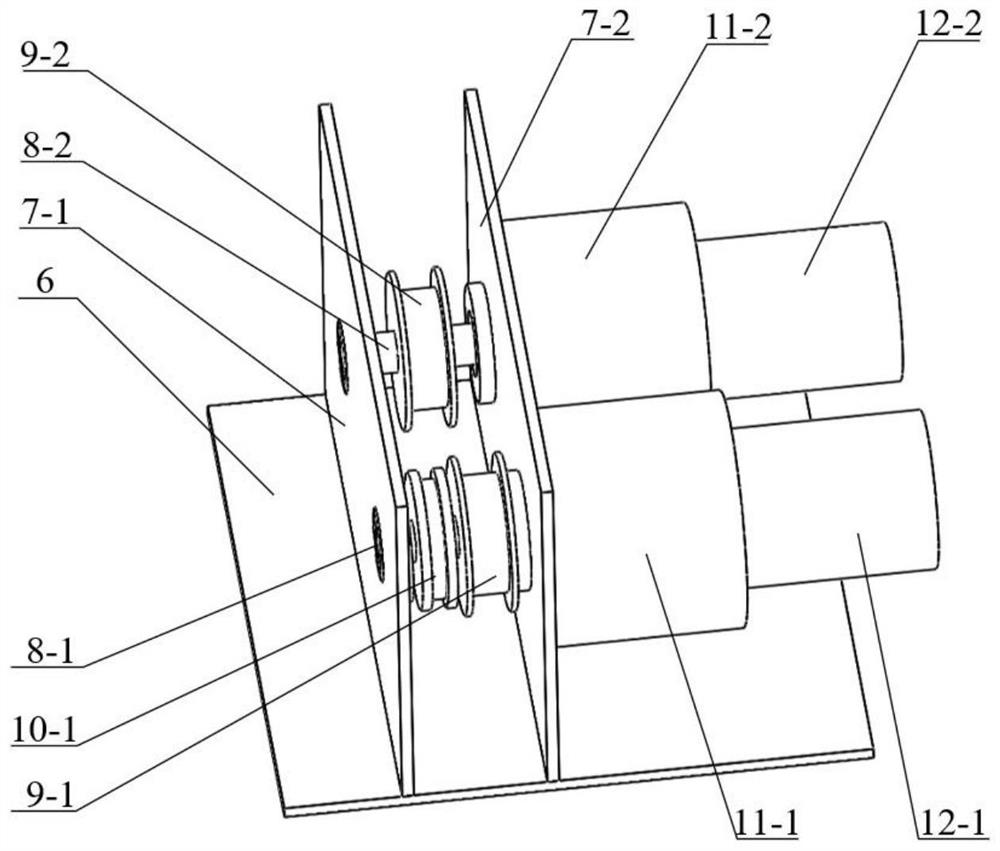

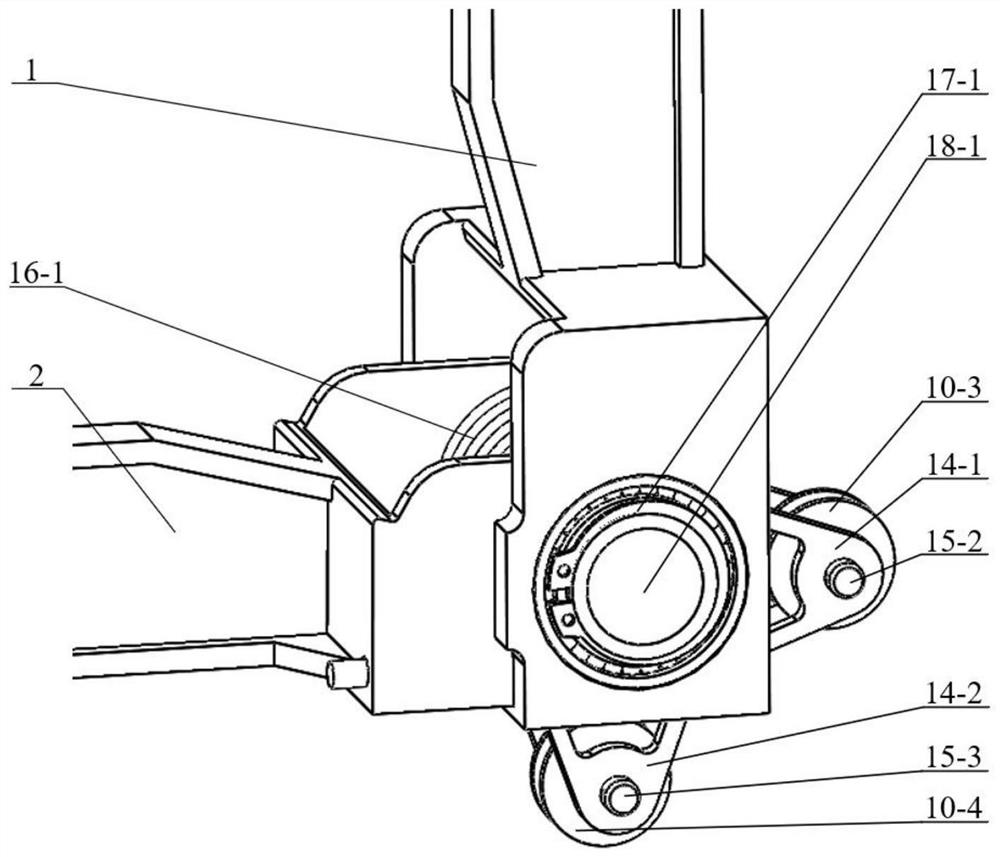

[0017] see Figure 1-4 , the present invention provides a technical solution: a spring return type rope-driven mechanical arm, the mechanical arm is provided with a base support plate 6, a driving mechanism is installed on one side of the base support plate 6, and the base supports The other side of the plate 6 is equipped with the head end of the upper arm 1, the tail end of the upper arm 1 is installed with the head end of the middle arm 2 through the shoulder joint torsion spring 16-1, and the tail end of the middle arm 2 is passed through the elbow joint torsion spring 16-2 installs the head end of the forearm 3; through the setting of the shoulder joint torsion spring 16-1 and the elbow joint torsion spring 16-2, the spring can be compressed and released when the shoulder joint rotates. At the same time, the upper arm 1 and the middle arm 2 are axially connected through the shoulder joint shaft 18-1, and the axial position is limited by the shoulder joint shaft spring 17-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com