Water gate pier spraying device for water conservancy project

A water conservancy project and spraying device technology, which is applied in spraying devices, liquid spraying devices, cleaning methods using tools, etc., can solve problems such as low work efficiency and paint precipitation, and achieve the effect of avoiding dragging, avoiding precipitation, and improving adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

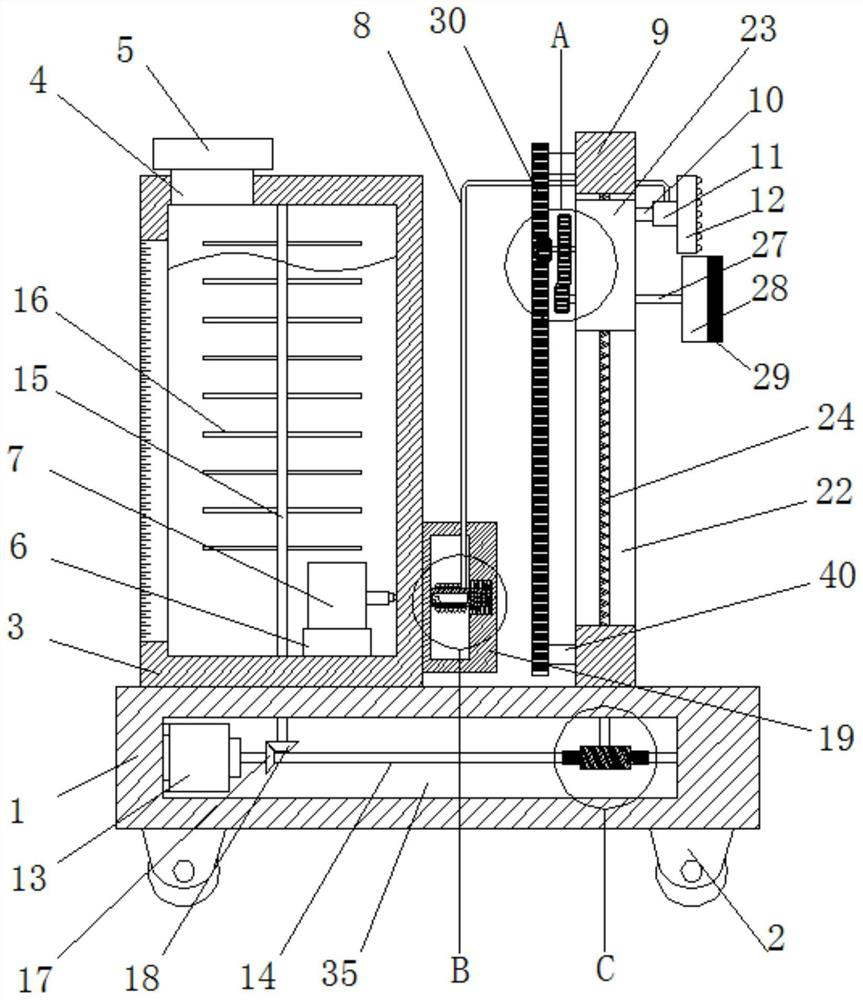

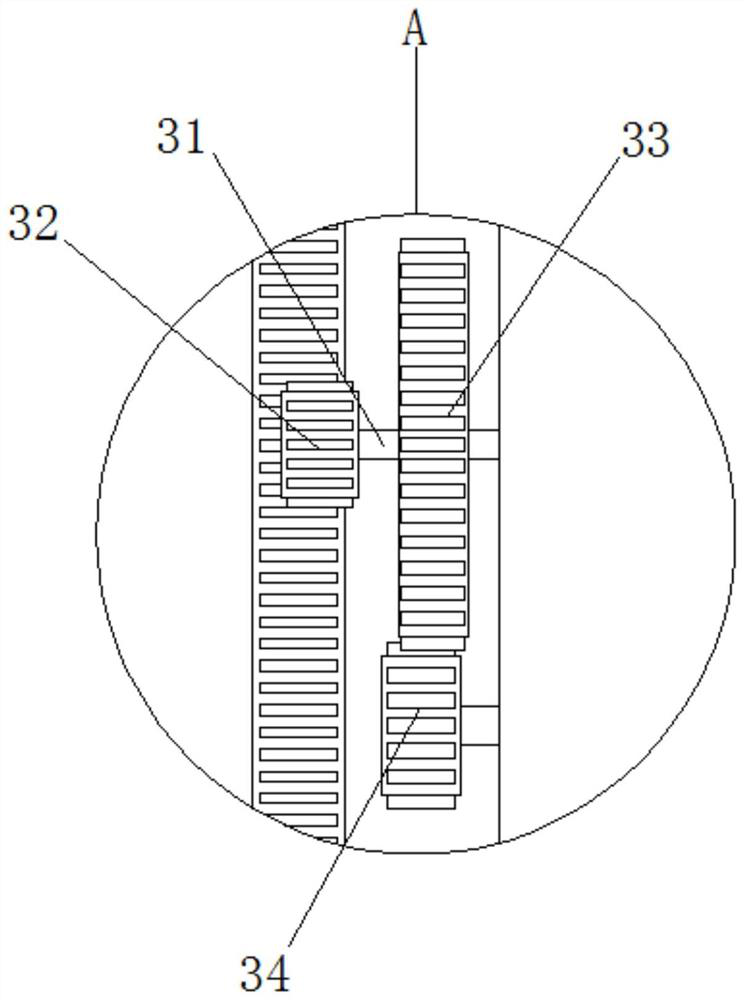

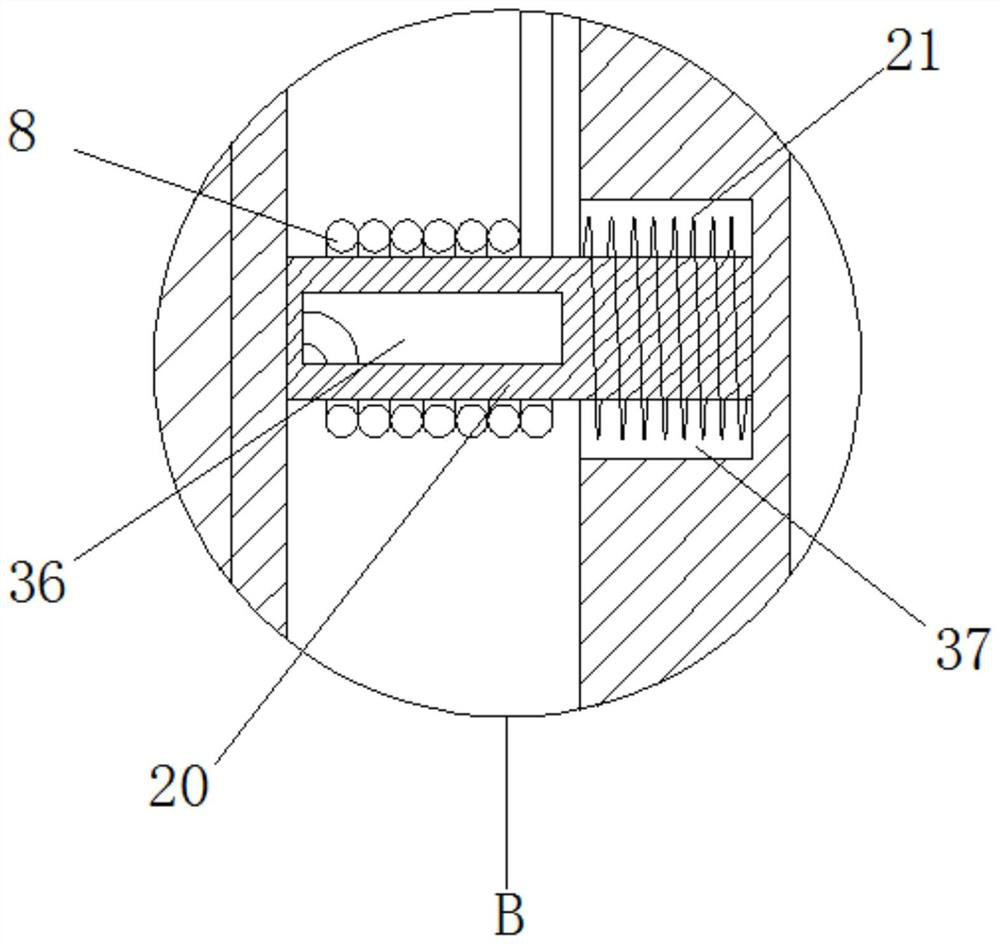

[0028] refer to Figure 1-5 , a water gate pier spraying device for water conservancy projects, comprising a base 1, a plurality of universal wheels 2 are arranged on the bottom of the base 1, a paint box 3 is arranged on the top of the base 1, and a feed pipe 4 is arranged on the top of the paint box 3 , the feed pipe 4 is provided with a sealing cover 5, the paint tank 3 is provided with a connecting seat 6, and the connecting seat 6 is provided with a booster pump 7, and the right side of the paint tank 3 is provided with a pipeline winding mechanism, and the pipeline winding mechanism A delivery leather tube 8 is wound on the top, and one end of the delivery leather tube 8 is rotatably connected to the output port of the booster pump 7. The top of the base 1 is fixedly connected with a vertical column 9 by welding, and the vertical column 9 is provided with a reciprocating displacement mechanism. Displacement mechanism is provided with connecting rod 10, and connecting rod...

Embodiment 2

[0039] The difference from Embodiment 1 is that it includes a base 1, a plurality of universal wheels 2 are arranged on the bottom of the base 1, a paint box 3 is arranged on the top of the base 1, a scale bar is arranged on the left side of the paint box 3, and the paint The top of the tank 3 is provided with a feed pipe 4, the feed pipe 4 is provided with a sealing cover 5, the paint tank 3 is provided with a connection seat 6, a booster pump 7 is provided on the connection seat 6, and the right side of the paint tank 3 is provided with a There is a pipeline winding mechanism, on which a delivery leather tube 8 is wound, and one end of the delivery leather tube 8 is rotatably connected to the output port of the booster pump 7, and the top of the base 1 is fixedly connected with a vertical column 9, and the vertical column 9 A reciprocal displacement mechanism is arranged on the upper surface, and a connecting rod 10 is arranged on the reciprocal displacement mechanism. The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com