Optical fiber ribbon optical cable with elastic wrapping cloth outer protective layer

An outer sheath and optical fiber ribbon technology, applied in the cable field, can solve the problems of high cost and inconvenience when the optical fiber ribbon cannot be replaced later for maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

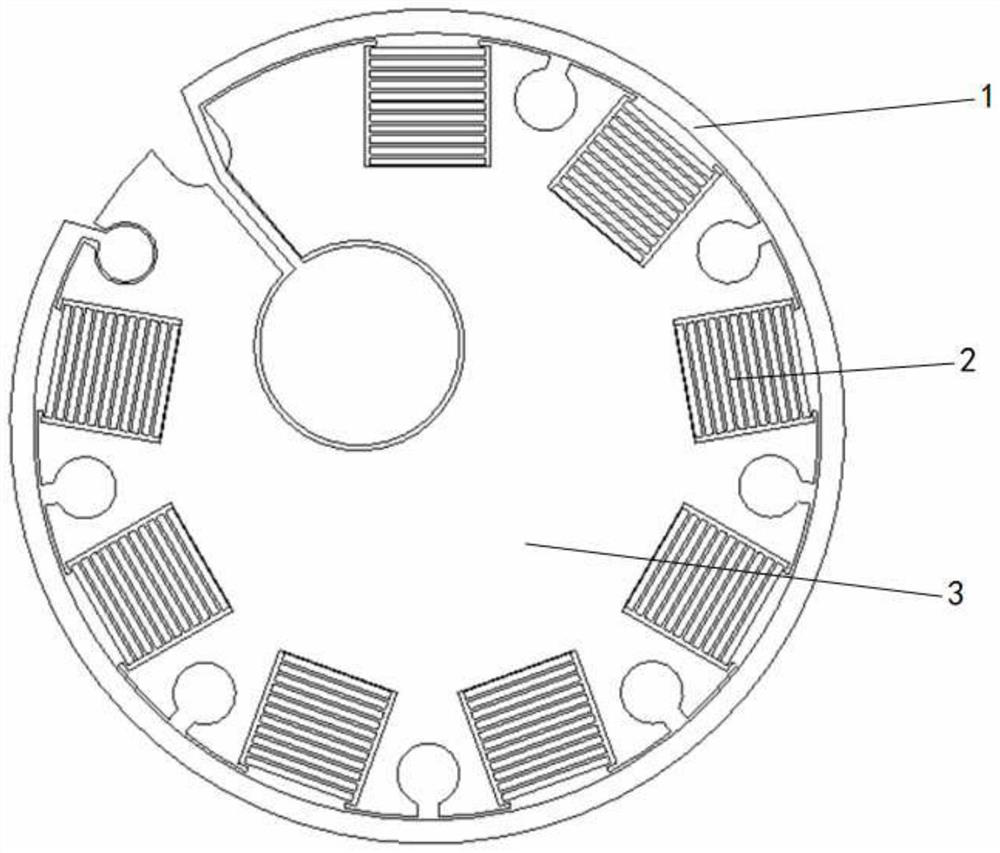

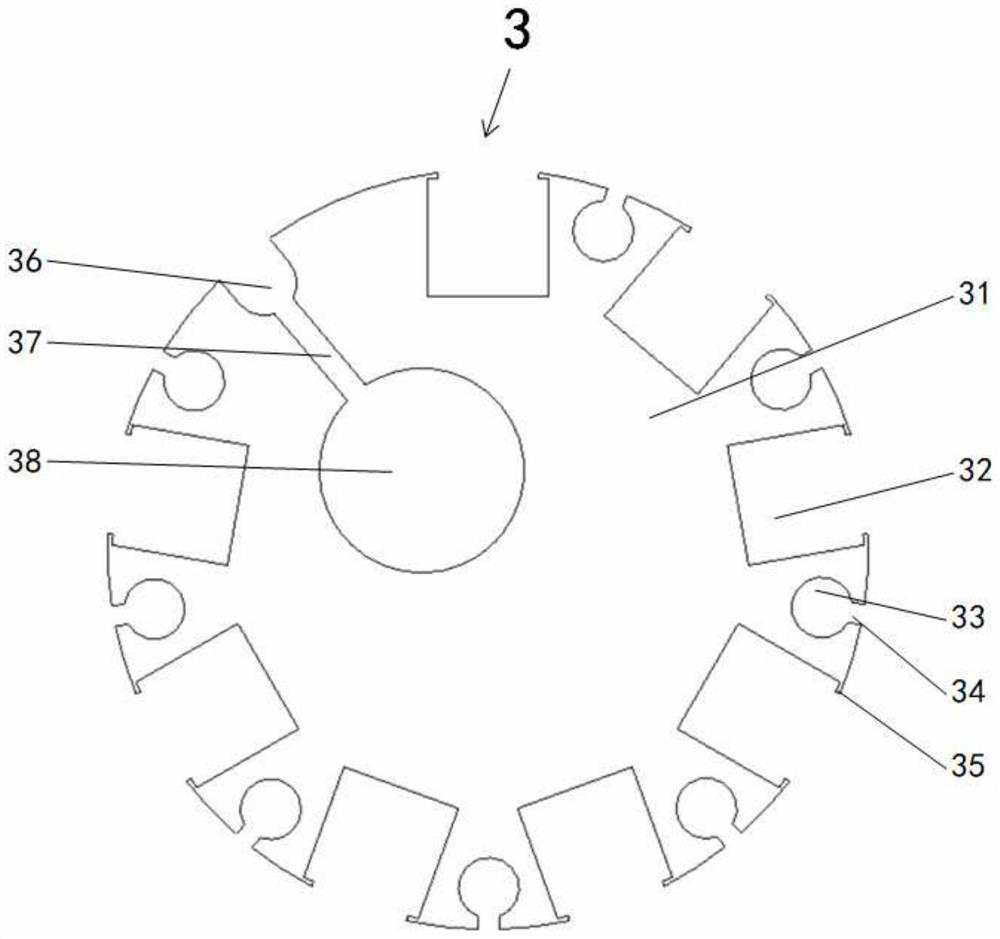

[0039] please see figure 1 , figure 2 with Figure 7 , an optical fiber ribbon cable with an elastic cloth outer sheath, has an outer sheath 1, a cable core 3 and an optical fiber ribbon body 2, and is characterized in that the cable core 3 is composed of a cable core body 31, and the cable core body 31 outer A plurality of open fiber-holding grooves 32 are formed around the edge, and an optical fiber ribbon body 2 is arranged in the fiber-holding grooves 32, and a clamping groove 33 is formed between two adjacent fiber-holding grooves 32, and each clamping groove 33 is formed toward the outside of the cable core. An embedding groove 34, the two ends of the opening of the fiber-holding groove 32 are provided with a third limiting block 35, the distance between the ends of the third limiting block 35 is less than the width of the optical fiber ribbon body 2, and one of the fiber-containing An open accommodating groove 36 is also formed between the groove 32 and the card groo...

Embodiment 2

[0043] please see image 3 , Figure 4 , Figure 5 with Figure 7 , an optical fiber ribbon cable with an outer sheath of elastic cloth, has an outer sheath 1, a cable core 3 and an optical fiber ribbon body 2, and is characterized in that the cable core 3 is composed of a cable core main body 31, and the outer sheath of the cable core main body 31 is A plurality of open fiber-holding grooves 32 are formed around the edge, and an optical fiber ribbon body 2 is arranged in the fiber-holding grooves 32. A clamping groove 33 is formed between two adjacent fiber-holding grooves 32, and each clamping groove 33 is formed toward the outside of the cable core. An embedding groove 34, the two ends of the opening of the fiber-holding groove 32 are provided with a third limiting block 35, the distance between the ends of the third limiting block 35 is less than the width of the optical fiber ribbon body 2, and one of the fiber-containing An open accommodating groove 36 is also formed be...

Embodiment 3

[0048] please see Figure 5 , Image 6 with Figure 7 , and refer to image 3 with Figure 4 , an optical fiber ribbon cable with an outer sheath of elastic cloth, has an outer sheath 1, a cable core 3 and an optical fiber ribbon body 2, and is characterized in that the cable core 3 is composed of a cable core main body 31, and the outer sheath of the cable core main body 31 is A plurality of open fiber-holding grooves 32 are formed around the edge, and an optical fiber ribbon body 2 is arranged in the fiber-holding grooves 32. A clamping groove 33 is formed between two adjacent fiber-holding grooves 32, and each clamping groove 33 is formed toward the outside of the cable core. An embedding groove 34, the two ends of the opening of the fiber-holding groove 32 are provided with a third limiting block 35, the distance between the ends of the third limiting block 35 is less than the width of the optical fiber ribbon body 2, and one of the fiber-containing An open accommodati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com