Measuring device and measuring method for mechanical parameters

A technology of mechanical parameters and measuring devices, which is applied in the field of mechanical parameter measurement, can solve the problems that the experimental results cannot be eliminated, occupy a large space, and affect the stability of the device, so as to meet the needs of scientific research and teaching practice, easy to operate, and avoid external The effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 provides a measuring device and method for mechanical parameters;

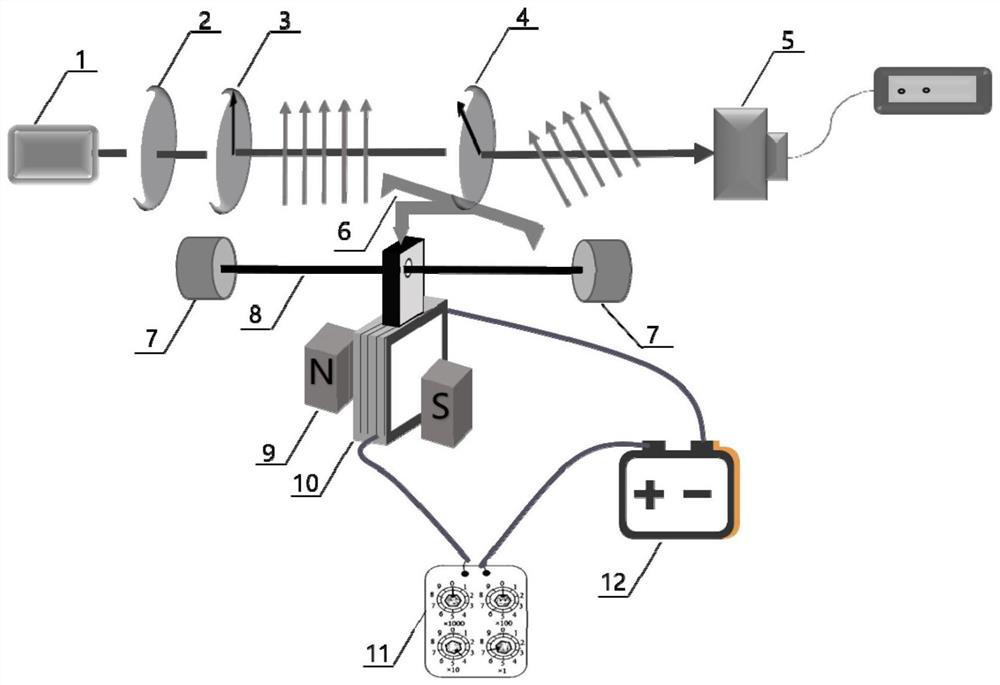

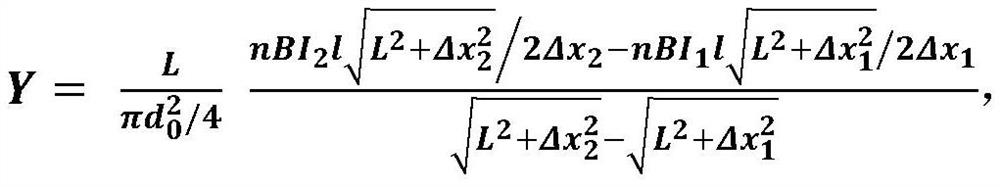

[0037] Such as figure 1 , the measuring device of the mechanical parameter of the present embodiment, comprises steel wire 8 to be measured, fixture 7, the square coil 10 that number of turns is n, the permanent magnet 9 that magnetic induction intensity is B, laser device 1, band-pass filter 2, the first Polarizer 3, second polarizer 4, tripod support 6, optical power meter 5, DC power supply 12 and resistor 11; the laser 1 and bandpass filter 2 provided in this embodiment are both 532nm;

[0038] Wherein the clamp 7 is used to fix the two ends of the steel wire 8 to be tested, and the square coil 10 with the number of turns m is vertically suspended at the midpoint of the steel wire to be tested, and placed in the middle of the two poles of the permanent magnet 9 whose magnetic induction is B. At the magnetic field; 532nm laser 1, 532nm band-pass filter 2, first polarizer 3, and optical ...

Embodiment 2

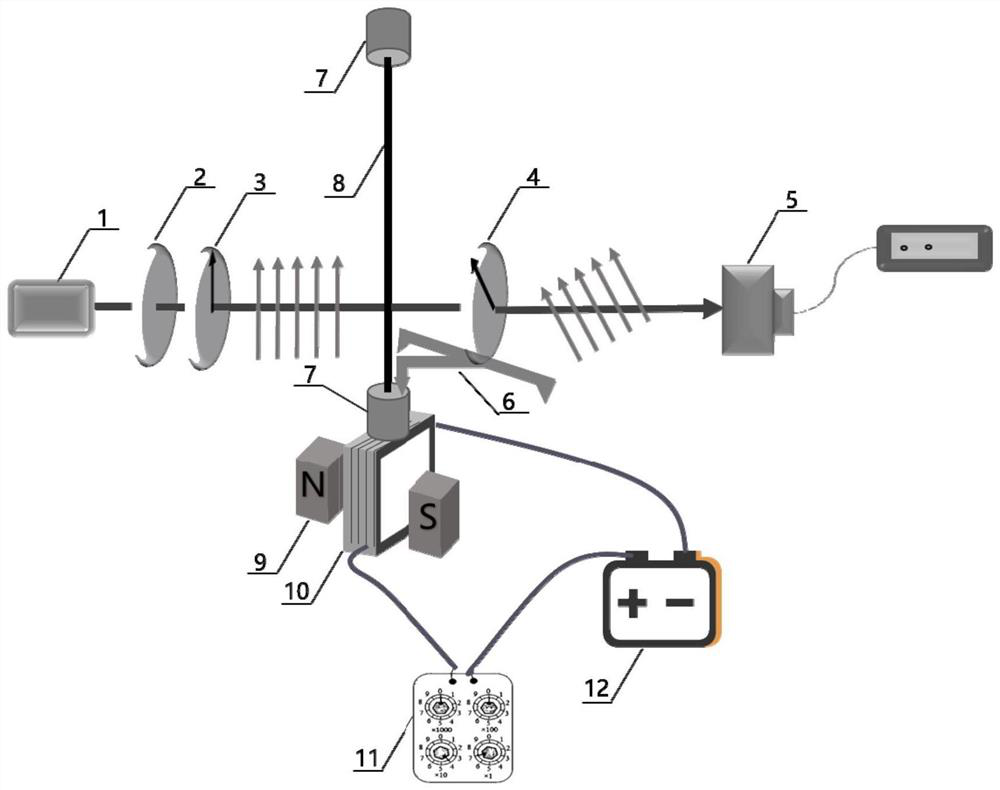

[0060] Embodiment 2 provides another measuring device for mechanical parameters and a corresponding measuring method; specifically:

[0061] Such as figure 2 , the structure of the device of this embodiment is the same as that of the first embodiment, the difference is that the laser 1 and the band-pass filter 2 are 488nm, and the material to be measured includes the fiber filament to be measured;

[0062] During specific measurement, the measuring method is the same as the embodiment, the difference is that the two ends of the fiber to be measured are fixed with clamps 7, so that the fiber to be measured is in a vertically suspended tension state, and the coil 10 is vertically suspended on the fiber to be measured. On the collet of the lower end fixture 7; the placement state of the material to be tested is different from that of Embodiment 1, which is also an essential difference.

[0063] When adjusting the current, gradually increase the current every 0.2A. In fact, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com