Method for replacing shaft casing of mining feeding well

A casing and wellbore technology, which is applied in the field of replacement of wellbore casings in mine feeding wells, can solve the problems that the wellbore casings cannot be repaired and replaced, delay the construction period, waste resources, etc., and achieve sustainable development and prolong the service life , Reduce the effect of manpower and material resources input and waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a method beneficial for replacing the shaft casing of a mine feeding well, which comprises a plurality of shaft casings, a flange assembly, a fixing device for the casing at the wellhead of the feeding well and a fixing device for the casing at the outlet of the feeding well. Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

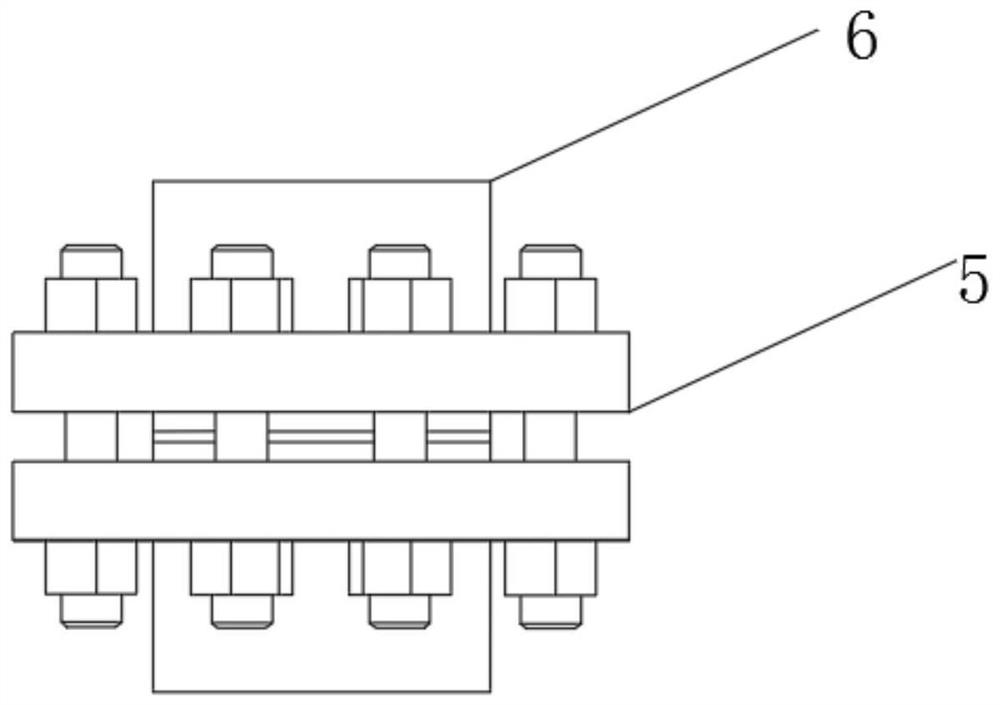

[0024] to combine figure 1 , figure 2 As shown, a method beneficial to replacing the shaft casing of the mine feeding well, including: a plurality of flange assemblies 5, a plurality of shaft casings 6, a casing fixing device 4 for the inlet of the feeding well, and a casing for the outlet of the feeding well Pipe fixing device 7, the wellbore casing 6 is a fixed unit length, and the wellbore casing 6 can be connected and disassembled through the flange assembly 5, and the feeding well inlet casing fixing device 4 is anchored to the feeding well At the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com