Construction method for joint of fabricated prefabricated wall and cast-in-place structure

A technology of prefabricated walls and construction methods, applied in the direction of walls, building components, building structures, etc., can solve problems such as high maintenance costs, easy cracks, and reduced quality and aesthetics of prefabricated buildings, so as to avoid maintenance costs, Guaranteed overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated below by specific examples.

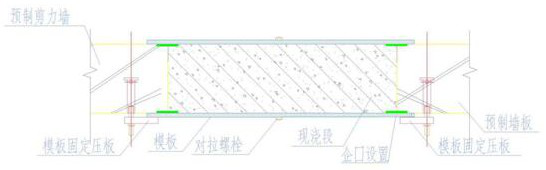

[0028] Such as figure 1 The anti-crack construction method for the junction of the fabricated prefabricated wall and the cast-in-place structure includes:

[0029] Step 1. Deepening of prefabricated components

[0030] Familiarize yourself with the drawings carefully before construction, and deepen the 5mm thick and 50mm wide joints at the junction of prefabricated components and cast-in-place nodes, and prefabricate the tongue and groove. And strictly control the rough surface of the prefabricated wall and cast-in-place section, which must be greater than 80%. It can increase the sticking area between the prefabricated components and the original concrete surface, increase the friction force, and increase the integrity of the prefabricated components and the cast-in-place parts.

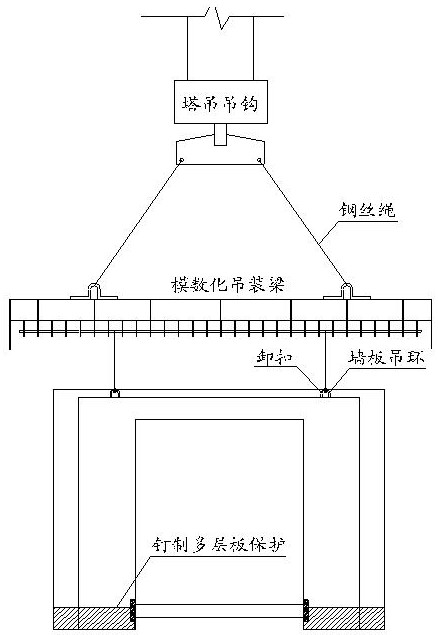

[0031] Step 2. Installation of prefabricated components

[0032] Step 2.1, component inspection

[0033] Before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com