Method for positioning bottom section and broadside section on heavy lift vessel

A positioning method and broadside technology, applied to ships and other directions, can solve the problems of low loading efficiency, inability to obtain the positioning accuracy of the general group, and unsatisfactory conditions, and achieve the effect of convenient and fast on-site work, reducing construction risks, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below we will further elaborate on the positioning method of the upper bottom section and the side section of the heavy lift ship in conjunction with the accompanying drawings and specific embodiments in order to understand its structural composition and working mode more clearly. The protection scope of the present invention cannot be limited by this.

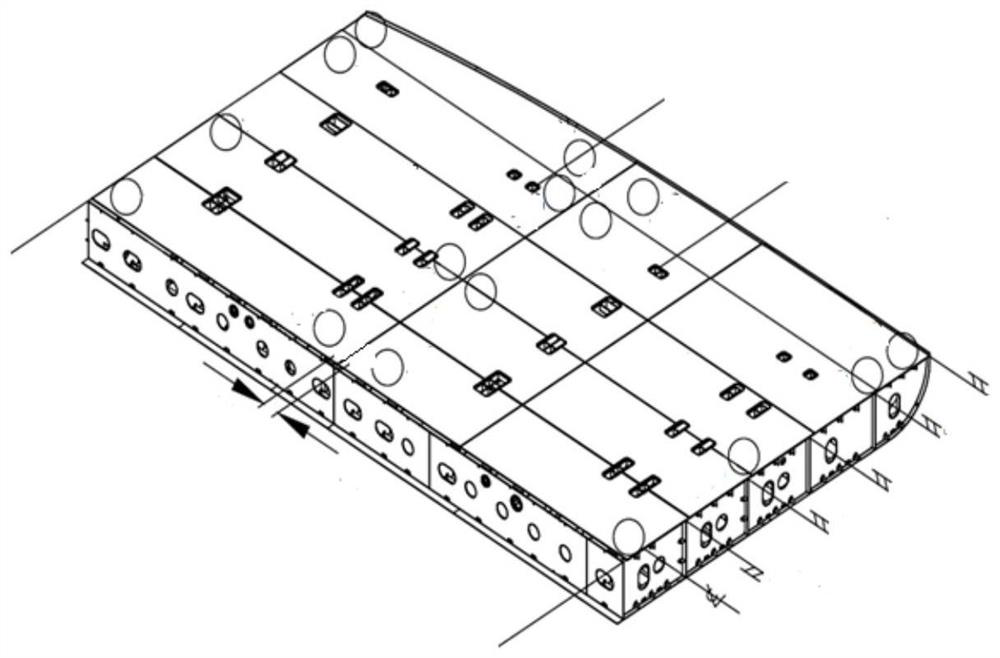

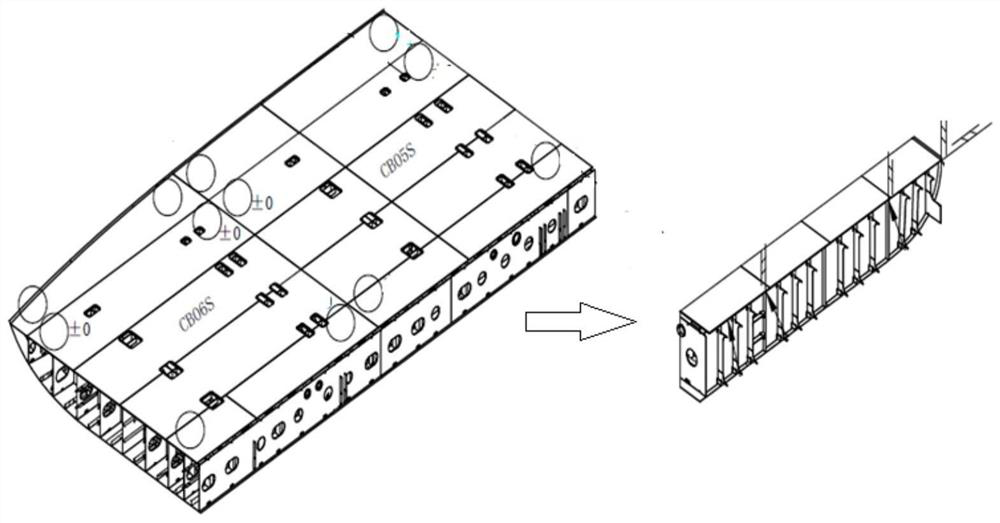

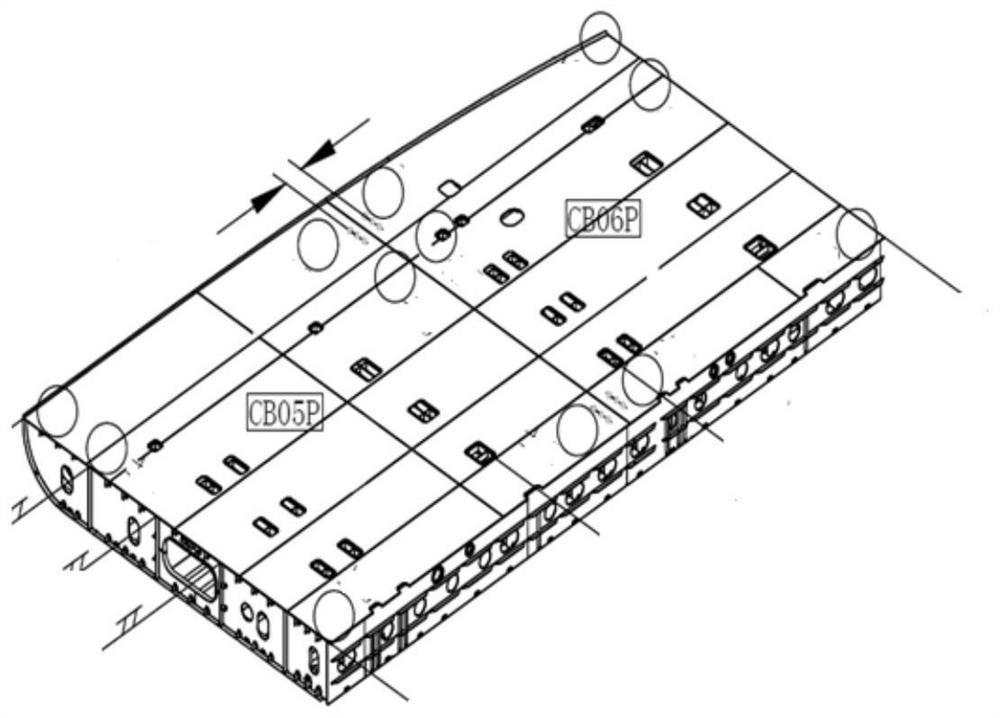

[0034] Such as Figure 1-Figure 5 As shown, the present invention is a positioning method for the upper bottom section and the side section of a heavy lift ship. The bottom section and the side section are arranged on the heavy lift ship, the bottom section is located at the bottom of the hull, and the side The side segments are arranged symmetrically on both sides of the hull, and the bottom of the side segments is connected to the bottom segment. The method of the present invention is mainly based on the utilization of the total station, and accurately adjusts the hoisting points of the upper bottom section and side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com