Bone screw

A technology of bone screw and screw rod, which is applied in the field of self-drilling and self-tapping bone screws, and can solve problems such as injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0017] Before the present invention is described in detail, it should be noted that in the following description, similar elements are denoted by the same numerals.

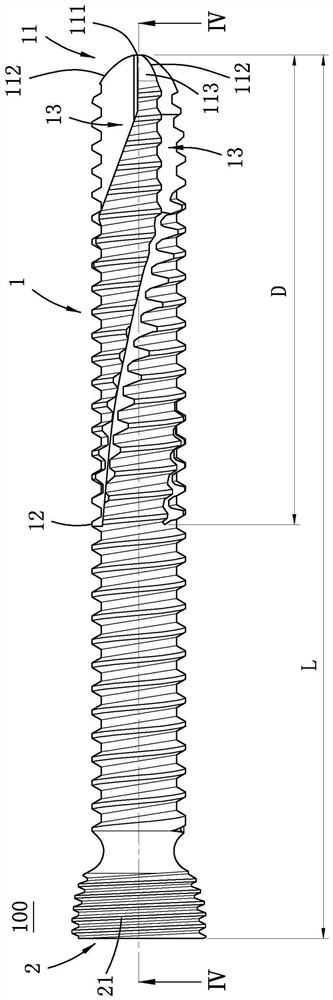

[0018] refer to figure 1 , an embodiment of the bone screw 100 of the present invention, the bone screw 100 is a self-drilling self-tapping bone screw and includes a screw shank 1 and a screw head 2 .

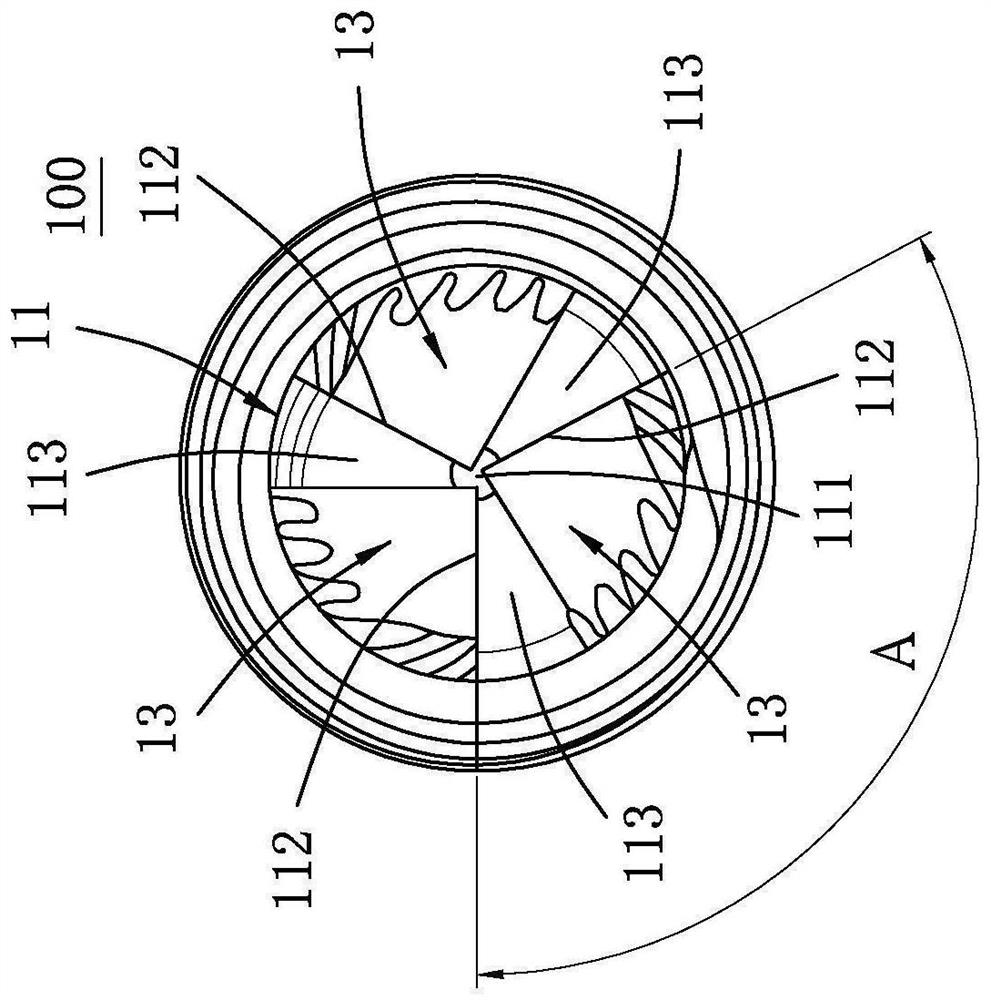

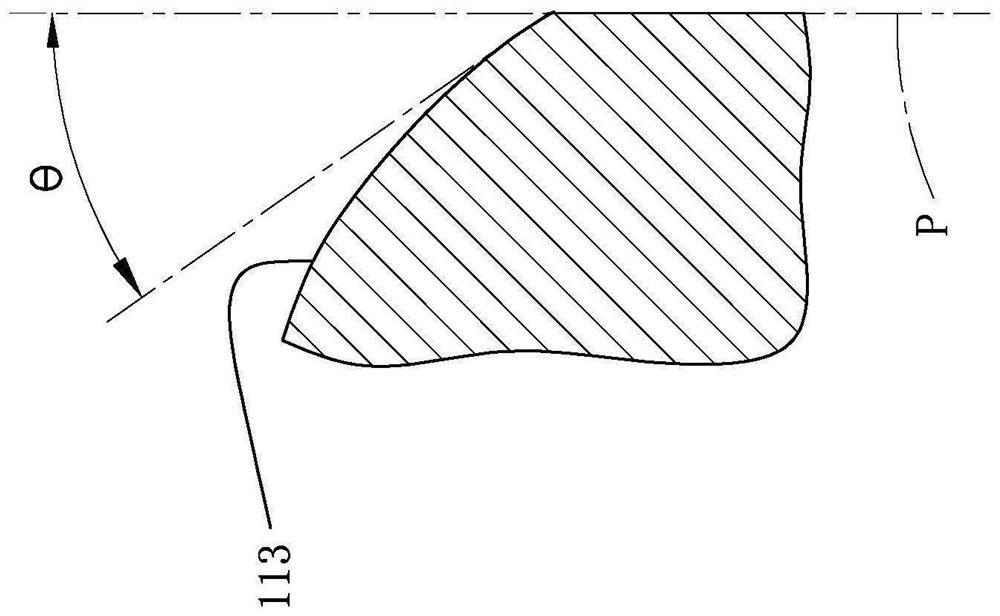

[0019] refer to figure 1 , figure 2 and image 3 , the nail shank 1 includes a tip section 11 and a first thread section 12 formed at one end of the tip section 11 . The tip segment 11 has an end portion 111 , a plurality of cutting edges 112 , and a plurality of relief surfaces 113 . The end portion 111 in this embodiment is a circular arc end face. The cutting edges 112 extend from the end portion 111 and are arranged at equiangular intervals. The number of the cutting edges 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com