Notebook binding device

A notebook and packaging technology, applied in the field of binding devices, can solve the problems of contaminating work space, contaminating glue liquid, retention, etc., and achieving the effects of improving neatness, avoiding accumulation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

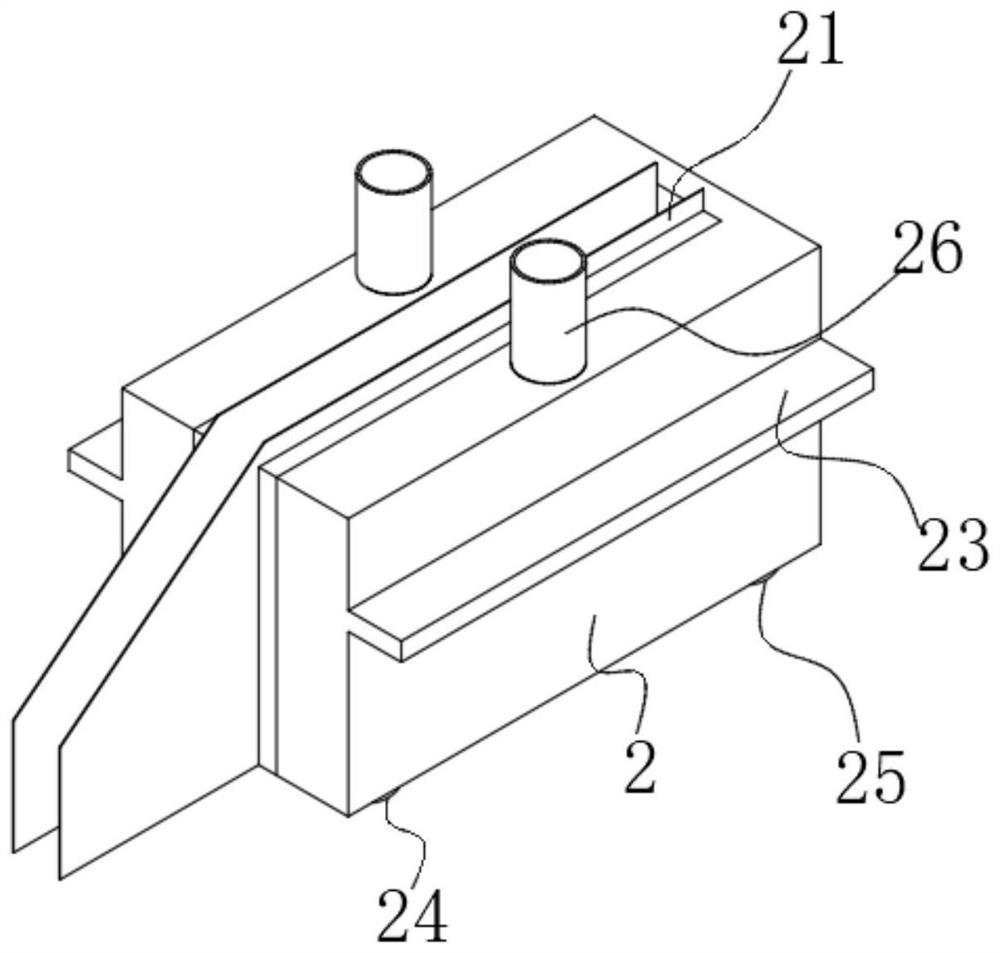

[0024] see Figure 1~2 , the present embodiment, a notebook binding device, including a machine base 1, a paper clamping slide 2, a paper milling wheel 3, a glue roller 8 and a cover packaging device 11, the paper clamping slide 2, the paper milling wheel 3, The gluing roller 8 and the cover packaging device 11 are sequentially arranged on the machine base 1 along the paper-feeding direction, the paper clamping slide table 2 is slidingly connected with the machine base 1 along the paper-feeding direction, and the milling wheel 3 is arranged to rotate along the vertical axis, The paper milling wheel 3 has two and is symmetrically arranged on both sides along the paper-feeding direction, and the base 1 is provided with a glue groove 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com