Excitation electronic retarder

A retarder and excitation technology, applied in electric vehicles, electrical components, circuit devices, etc., can solve problems such as increasing vehicle fuel consumption, not setting a reverse gear, increasing the burden on vehicle generators, and reducing the probability of sideslip, The effect of reducing power consumption and reducing braking distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings. But not as any limitation basis of the present invention:

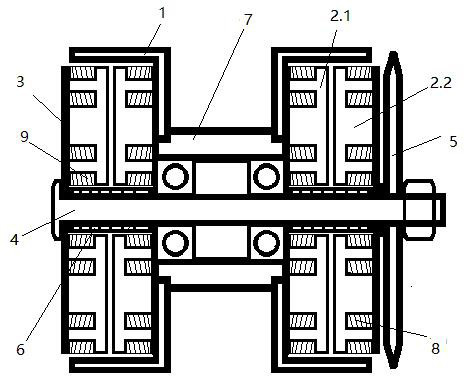

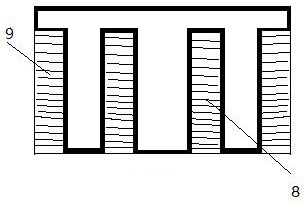

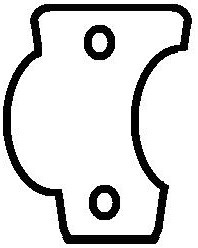

[0033] The excitation electronic retarder includes a cover plate 1, a first electromagnet core 2.1, a second electromagnet core 2.2, an iron core fixing plate 3, a central shaft 4, a sprocket 5, and a permanent magnet core 10. It is characterized in that: the excitation The electronic retarder also includes a sliding electrode 6, a connecting seat 7, a primary coil 8, and a secondary coil 9;

[0034] What is claimed: the first electromagnet core 2.1 and the second electromagnet core 2.2 are respectively provided with a primary coil 8 and a secondary coil 9 .

[0035] What is said: the primary coil 8 and the secondary coil 9 make the first electromagnet core 2.1 and the second electromagnet core 2.2, after the respective sliding electrodes 6 connected to it are energized alternately, can produce differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com