High-sensitivity microwave microfluidic sensor based on improved split-ring resonator

A split resonant ring, high-sensitivity technology, applied in the microwave field to reduce equipment sensing costs, avoid errors, and reduce detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

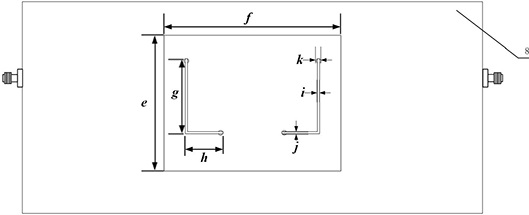

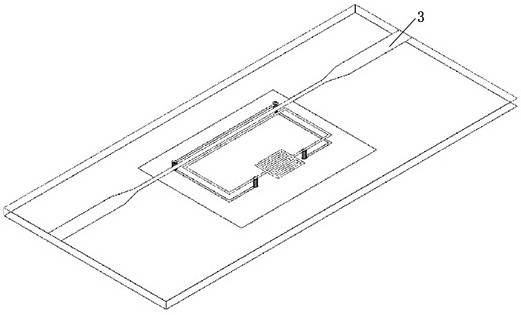

[0030] Example: such as Figure 1 to Figure 3 As shown, the high-sensitivity microwave microfluidic sensor based on the improved split resonant ring is a dual-port device; it has a three-layer structure with a top layer, a middle layer and a bottom layer; the SMA connector 2 on the top layer is welded to the main microstrip line 3 two Side, the side microstrip line 4 and the IDC-SRR structure 7 are coupled next to the main microstrip line 3 with a distance of 0.2 mm. The middle layer is a Rogers 4350 dielectric board 1 and four metal vias 6 . A rectangular area is etched in the metal sheet 8 at the bottom layer, and there are two microstrip lines in the area, each connecting two via holes to the side microstrip line 4 and the IDC-SRR structure 7 at the top layer. Place a PDMS on the area 5 with the maximum electric field strength, and a microfluidic channel is dug inside, and slowly inject 0%-100% ethanol in 10 times through a 100mL syringe at the water inlet of the channel w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com