Vacuum package flattening device for quick-frozen food processing

A vacuum packaging and quick-frozen food technology, applied in packaging, transportation and packaging, special packaging items, etc., can solve the problems that quick-frozen food cannot be evenly distributed, quick-frozen food is damaged, etc., to promote effective flattening, improve quality, and improve linkage sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

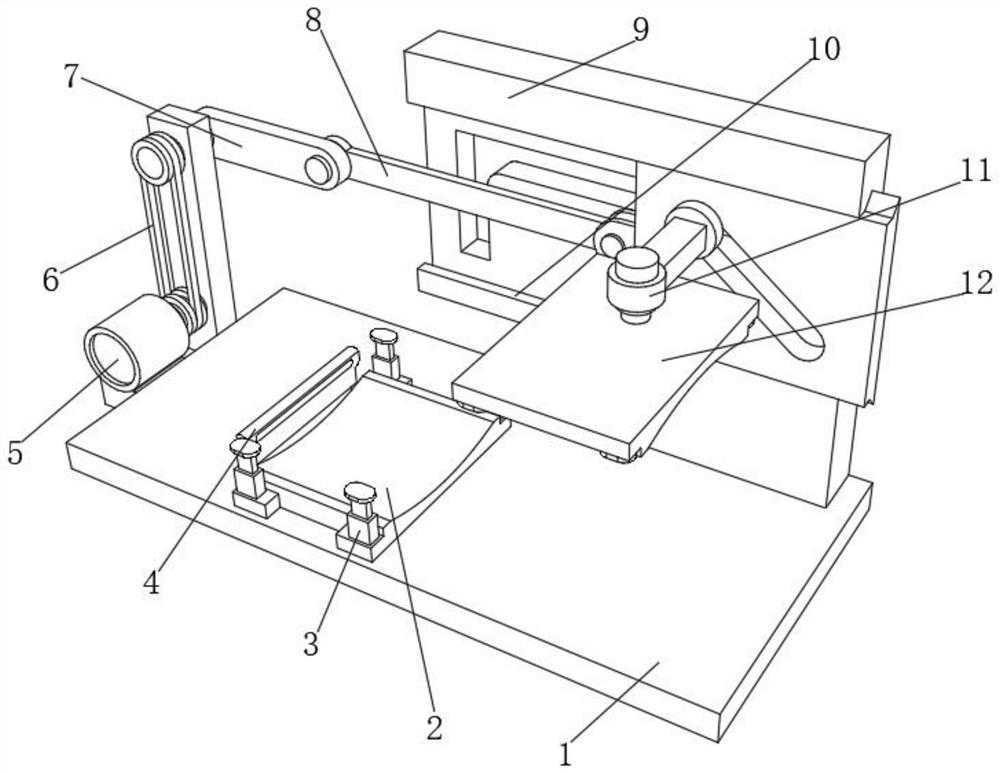

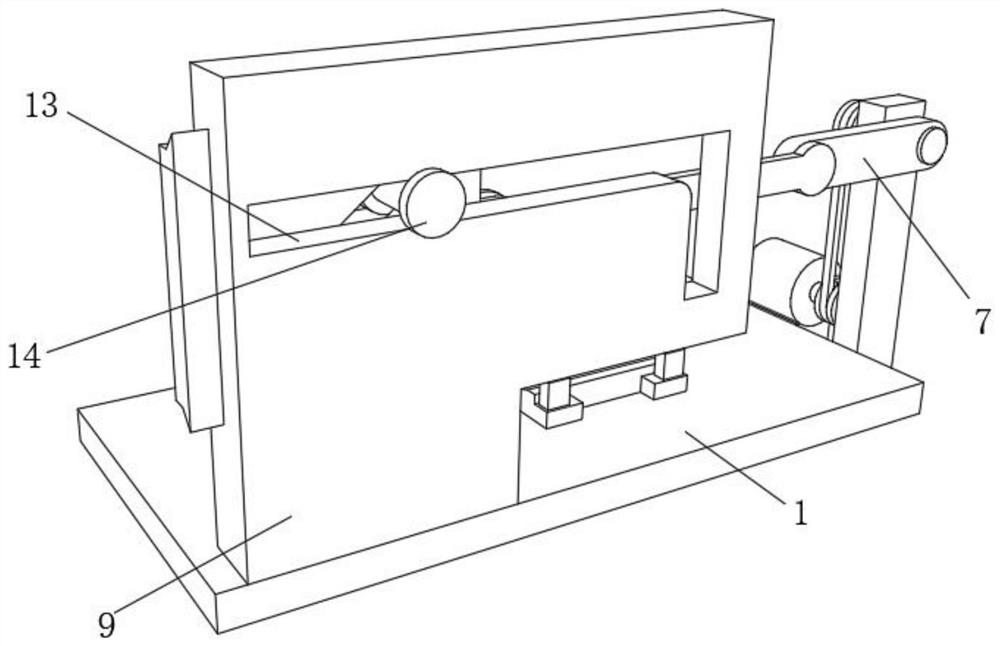

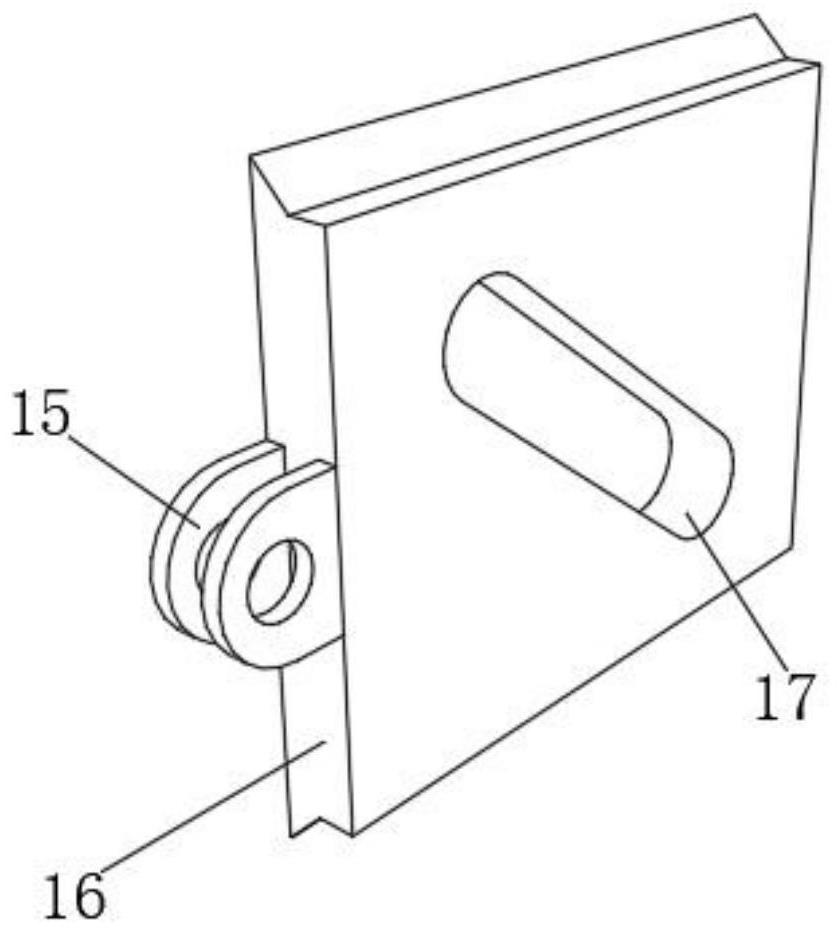

[0033] A vacuum packaging flattening device for quick-frozen food processing, such as Figure 1-4 As shown, it includes a base 1, the outer wall of one side of the base 1 is fixed with a motor 5 through a support block, and the outer wall of the base 1 close to the motor 5 is fixed with a bracket through bolts, and the output end of the motor 5 is connected with a guide shaft through a thread , and the guide shaft is connected to the bracket through the bearing, the top side of the bracket is fixed with the connecting shaft through the bearing, the outer circumference walls of the connecting shaft and the guide shaft are respectively sleeved with transmission wheels, and the circumference outer walls of the two transmission wheels are sleeved with With the same transmission chain 6, the top side of the base 1 is fixed with a support plate 9 by bolts, and the front side of the support plate 9 is provided with a chute 10, and a slide plate 16 is slidably connected in the chute 10...

Embodiment 2

[0040] A vacuum packaging flattening device for quick-frozen food processing, such as Figure 5 As shown, in order to press the uniformity of the quick-frozen food in the packaging bag; this embodiment makes the following improvements on the basis of embodiment 1: the bottom structure of the pressing plate 12 is an arc structure, and the bottom of the pressing plate 12 passes through the rotating shaft 22 respectively. It is connected with arc-shaped rubber blocks 23 distributed equidistantly; through multiple groups of arc-shaped rubber blocks 23, its bottom surface and the surface of the packaging bag are attached to each other, which ensures that when the quick-frozen food in the packaging bag is pressed by the pressing plate 12, each The uniformity of corner flattening improves the flattening quality of quick-frozen food.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com