Dismounting device for motor maintenance and operation method

A technology for dismantling devices and motor bases, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of stator damage, winding removal time-consuming and labor-intensive, etc., and achieve the effects of balanced force, high cutting efficiency and stable cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

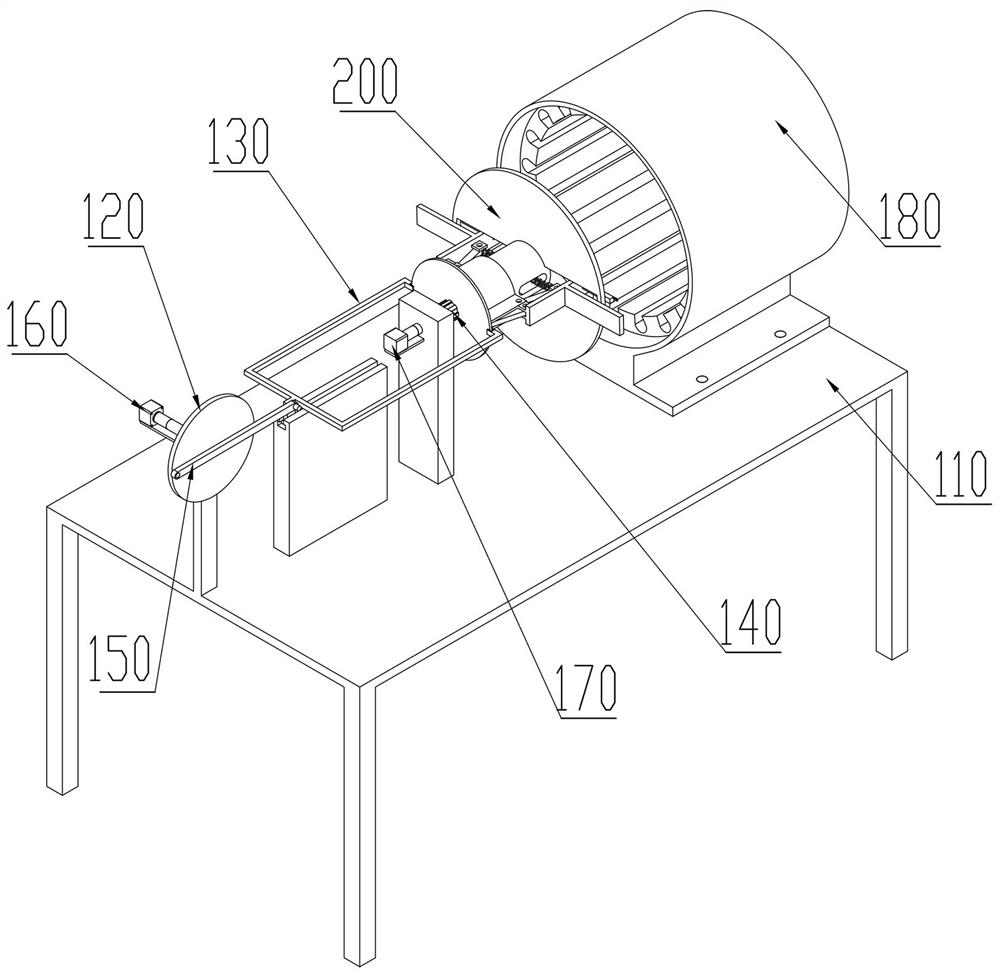

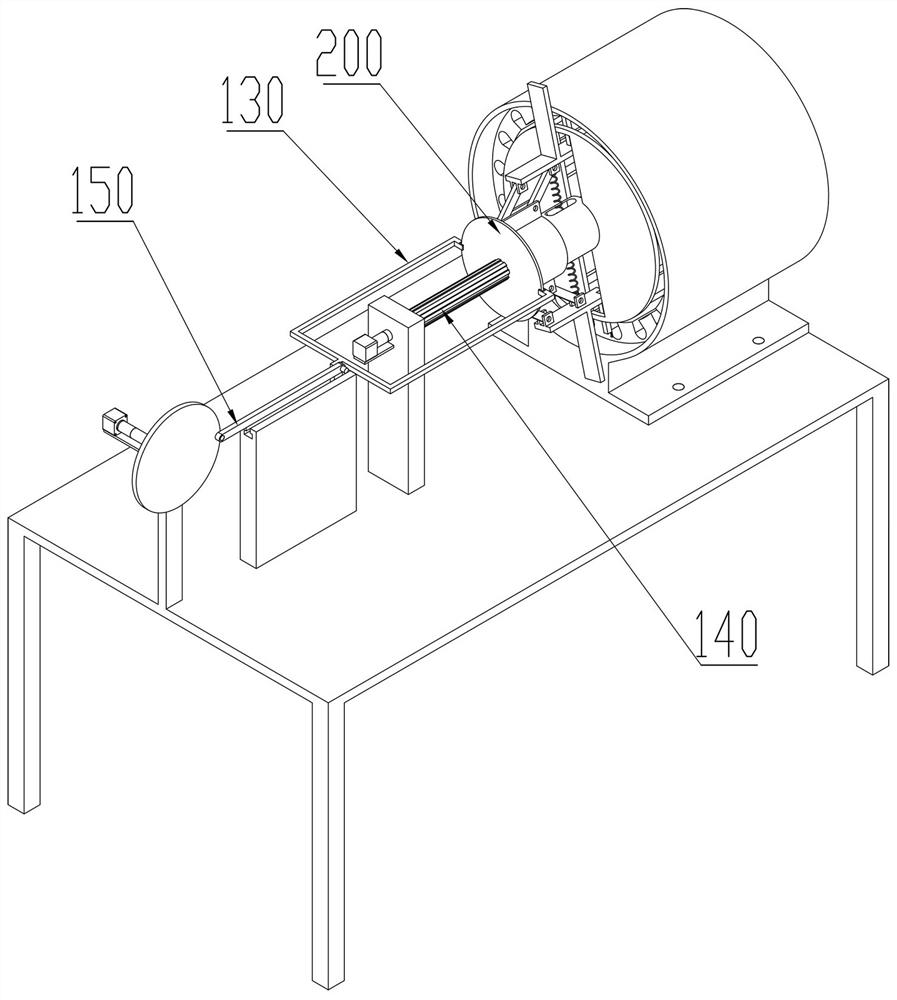

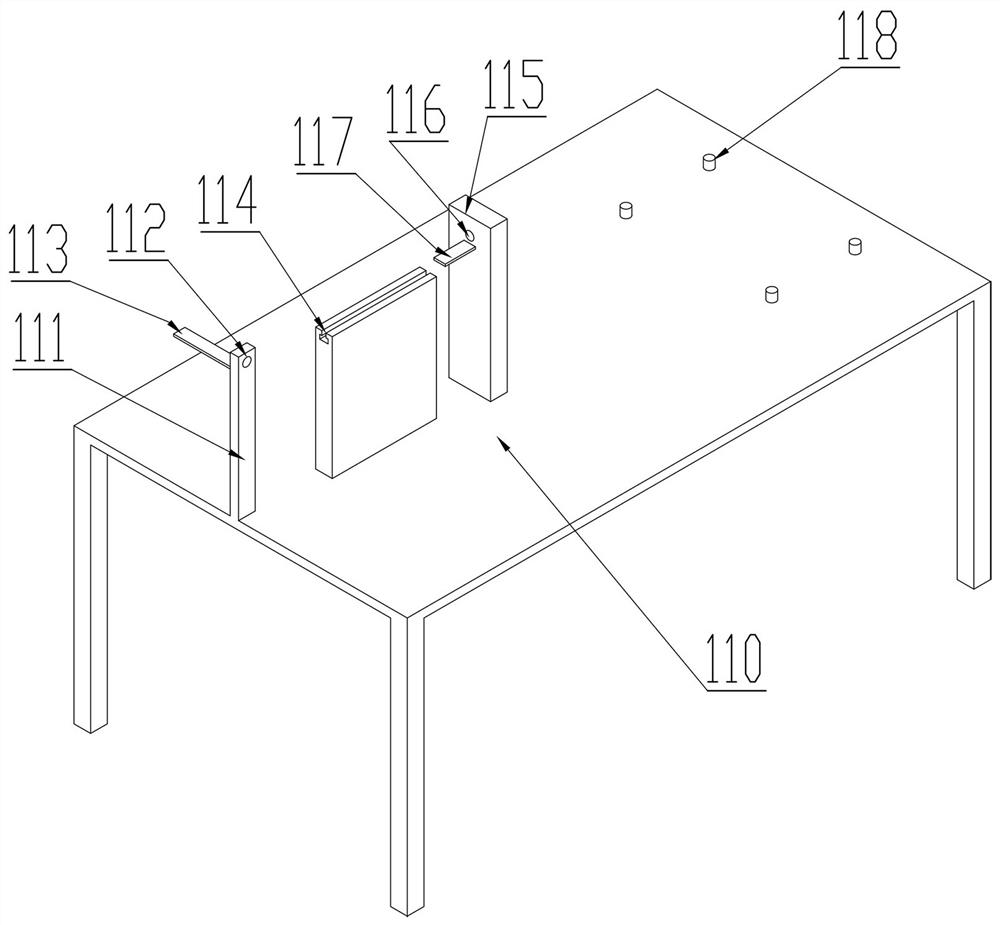

[0025] A dismantling device for motor maintenance, including a workbench 110, an eccentric wheel 120, a slider 130, a spline shaft 140, and a cutting device 200. The cutting device 200 includes a swivel seat 210, a sliding sleeve 220, and a bracket 230. The left side of the workbench 110 has a left support 111, the left support 111 top has a left support hole 112, the rear side of the left support hole 112 has a No. Support 115, right support 115 upper side has right support hole 116, right support hole 116 left side has No. There is an eccentric shaft 122 on the side of the wheel 120. The eccentric shaft 121 is connected to the left support hole 112 by rotation. The eccentric wheel 120 rotates in the left support hole 112. The eccentric shaft 121 passes through the left support hole 112. The eccentric shaft 121 is fixed to the output shaft of the No. 1 mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com