Vibration liquid level sensor

A liquid level sensor, No. 1 technology, applied in the field of sensors, can solve problems such as affecting the rise of the magnetic floating ball, and achieve the effect of avoiding waste and preventing corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] As an embodiment of the present invention, the No. 1 power unit 401 and the No. 2 power unit 12 are both motors.

[0053] During the use of the vibrating liquid level sensor, by setting the No. 1 power unit 401 and No. 2 power unit 12 as motors, they can be driven with a small amount of energy and can be precisely controlled to avoid energy waste.

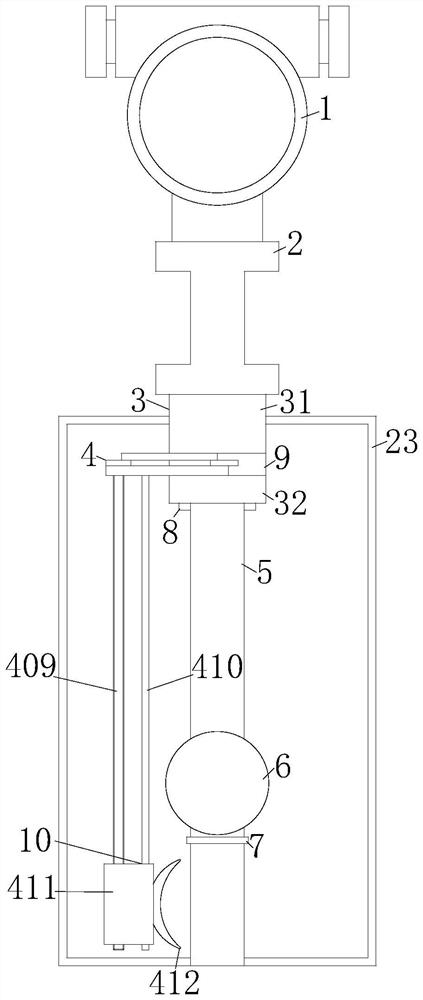

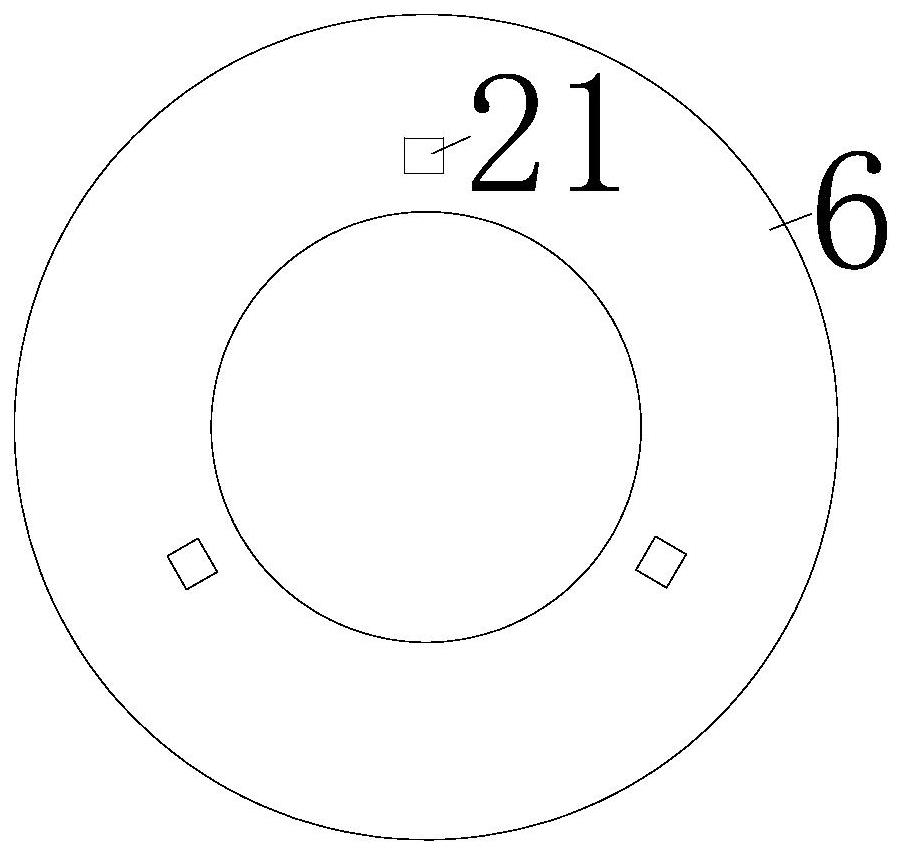

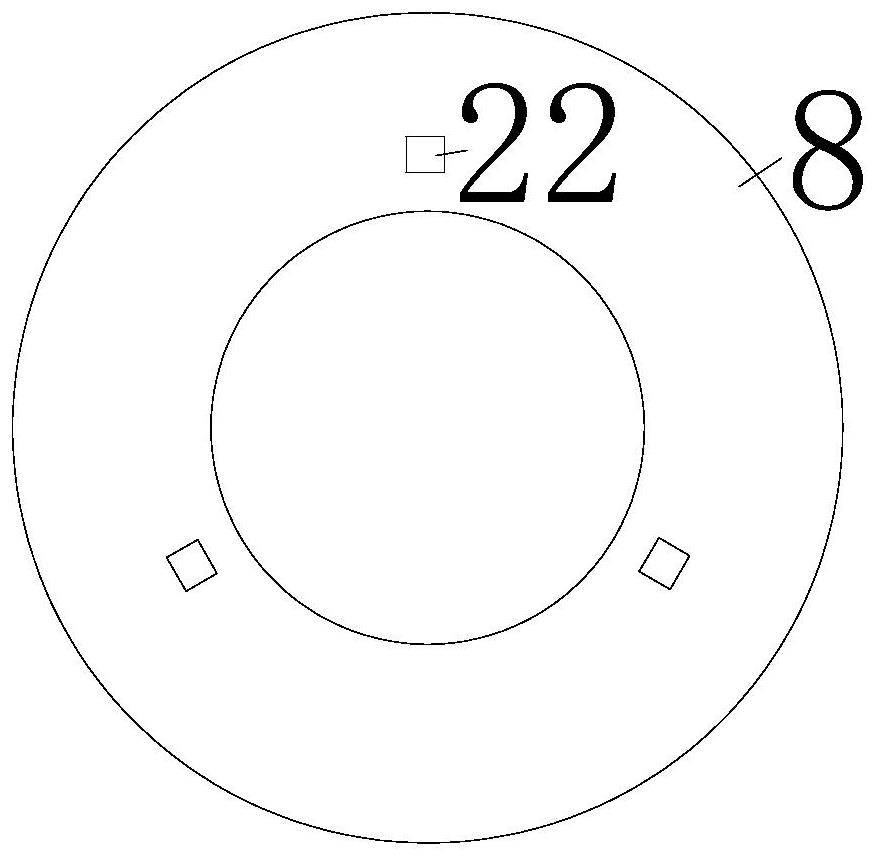

[0054] Working principle: when the present invention is installed, by setting the installation flange 2, the installation flange 2 is installed at the installation place, and the measuring rod 5 is submerged in the water to be measured. At this time, the magnetic floating ball 6 sinks and floats in the water, so that The magnetic induction electronic component 17 on the upper end of the electronic component circuit board 16 on the same horizontal line as the magnetic float 6 senses the magnetic induction line, and then different liquid level signals can be transmitted to different water levels, and the liquid level informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com