Plastic pipeline quick connecting pipe fitting and mounting method thereof

A technology of quick connection and plastic pipes, which is applied in the direction of pipe connection layout, pipe/pipe joint/fitting, clamp, etc., which can solve the disadvantages of fast installation, professional construction operation is difficult, and it is difficult to meet the use of light and fast installation Requirements and other issues to achieve the effect of improving the speed of pipeline connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

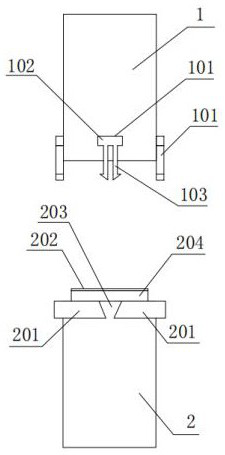

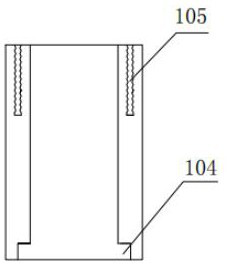

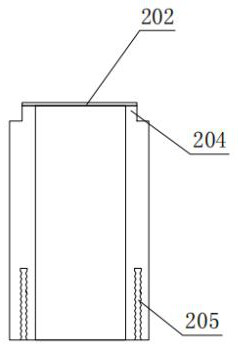

[0032] A quick-connect pipe fitting for a plastic pipe, comprising a pipe fitting A1 and a pipe fitting B2, four clamping sub-parts 101 are welded on the outer wall of one end of the pipe fitting A1, and four clamping female parts 201 are welded on the outer wall of one end of the pipe fitting B2, and A clamping gap 203 is provided between two adjacent clamping female parts 201 , and the clamping sub-component 101 is inserted into the clamping gap 203 between the pipe part A1 and the pipe part B2 for clamping and fixing.

[0033] The clamping sub-part 101 includes a fixed block 102 and two hooks 103, the fixed block 102 is fixed on the outer wall of the pipe A1, and the two hooks 103 are symmetrically arranged on the bottom of the fixed block 102; the clamping female part 201 includes a female The main body of the main body, the two sides of the main body of the female body are inclined, so that the clamping gap 203 between the clamping female components 201 gradually decreases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com