Semi-automatic forming device for watercolor packaging

A forming device and semi-automatic technology, which is applied to the types of packaging items, packaging, transportation packaging, etc., can solve problems such as long time and unable to meet the requirements of the construction period, and achieve the effect of convenient winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

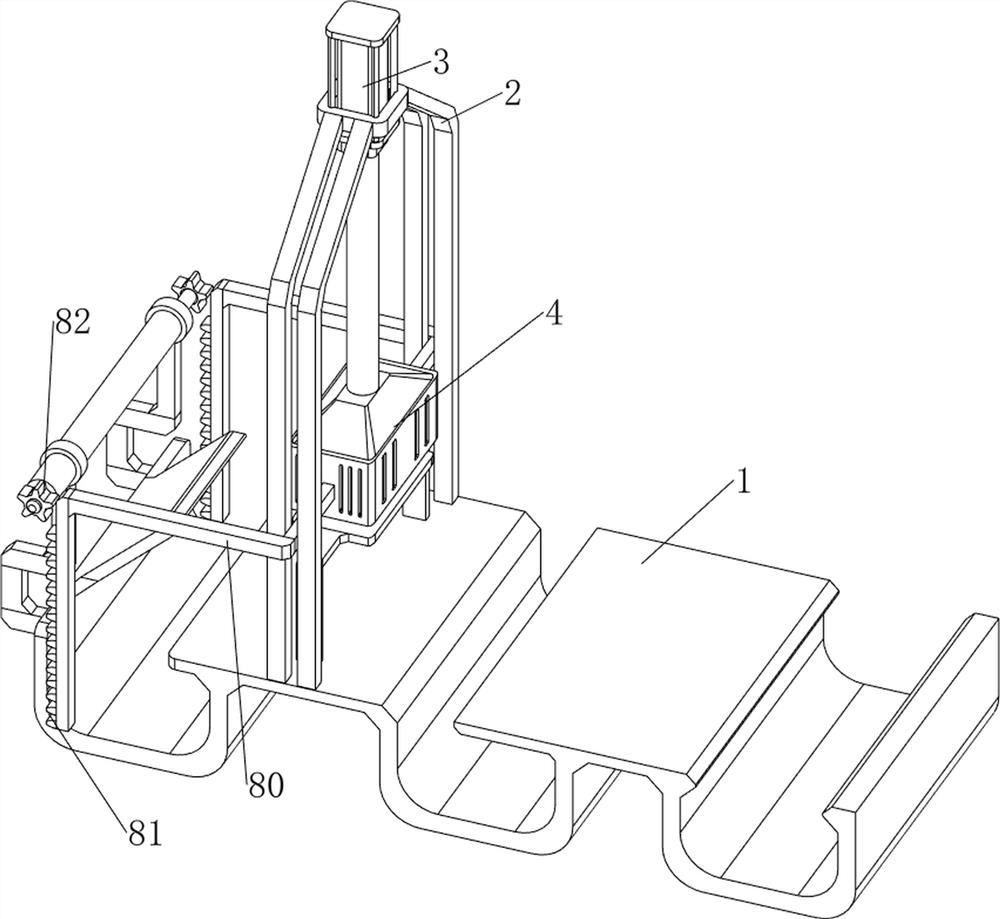

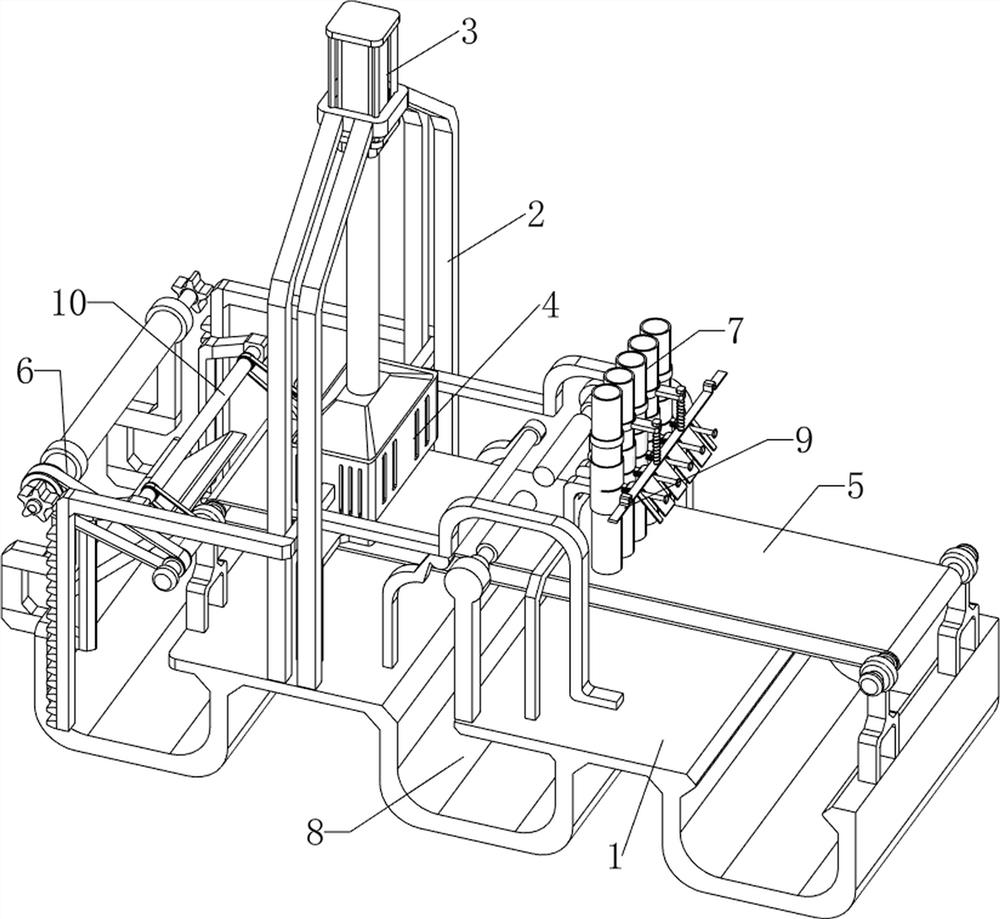

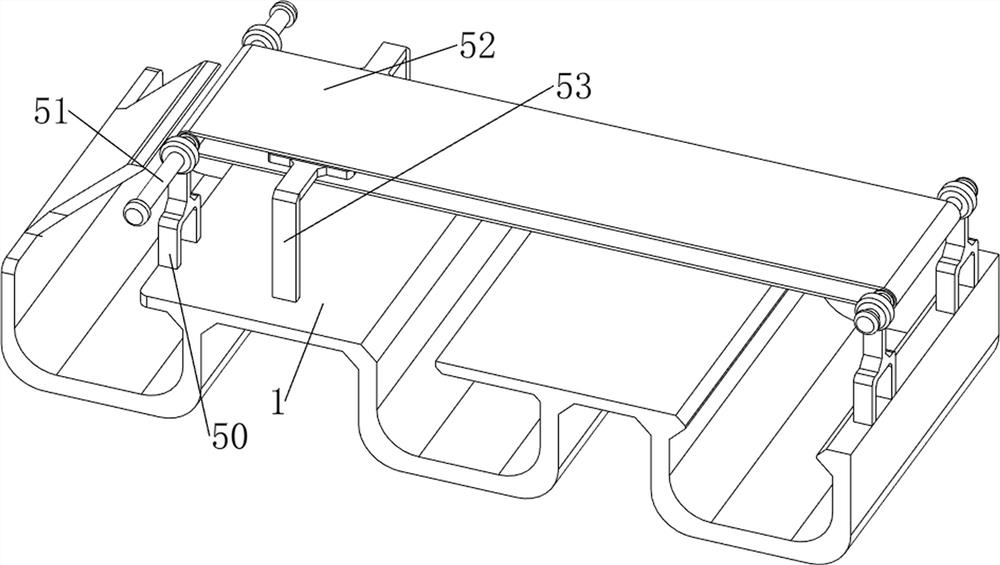

[0060] A semi-automatic forming device for watercolor packaging, such as Figure 1-5 As shown, it includes a bottom plate 1, a support frame 2, a cylinder 3, a lower pressure block 4, a transmission mechanism 5, a transmission mechanism 6 and a manual unloading mechanism 7. There is a cylinder 3, and the telescopic rod of the cylinder 3 is equipped with a lower pressing block 4, and the bottom of the lower pressing block 4 is provided with a heating wire, which can better seal the tin foil. The side is provided with a transmission mechanism 6, and the right side of the bottom plate 1 top is provided with a manual unloading mechanism 7, and the manual unloading mechanism 7 is located on the left side of the transmission mechanism 5.

[0061]When the watercolor needs to be packaged, first people put the formed watercolor into the manual unloading mechanism 7, and at the same time place the packaging shell for the watercolor on the top of the transmission mechanism 5, and people ...

Embodiment 2

[0069] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 and Figure 8 As shown, a rotating mechanism 8 is also included. The rotating mechanism 8 includes a first connecting plate 80, a rack 81 and a one-way gear 82. The front and rear sides of the lower pressing block 4 are provided with a first connecting plate 80, and two second connecting plates 80 are provided. A rack 81 is provided on the left side of the connecting plate 80 , and a one-way gear 82 is provided on the front and rear sides of the second rotating shaft 61 , and the one-way gear 82 meshes with the rack 81 .

[0070] When the lower pressing block 4 moves downward, the lower pressing block 4 drives the first connecting plate 80 to move downward, and the first connecting plate 80 drives the rack 81 to move downward, and the rack 81 moves downward and one-way The gear 82 touches and does not react, and then the lower pressing block 4 drives the first connecting plate 80 to move upward, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com