Full-automatic nozzle cap film sealing system and film sealing method thereof

A fully automatic, mouth cover technology, applied in packaging sealing/fastening, transportation packaging, packaging, etc., can solve problems such as labor, sealing film is not very efficient, product damage, etc., and achieve the effect of easy cutting and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

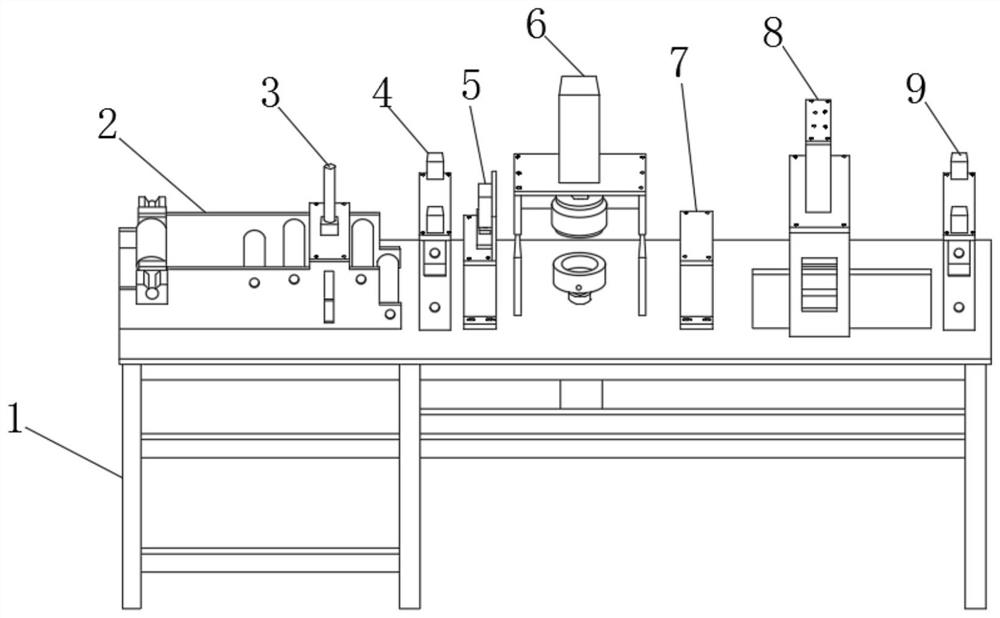

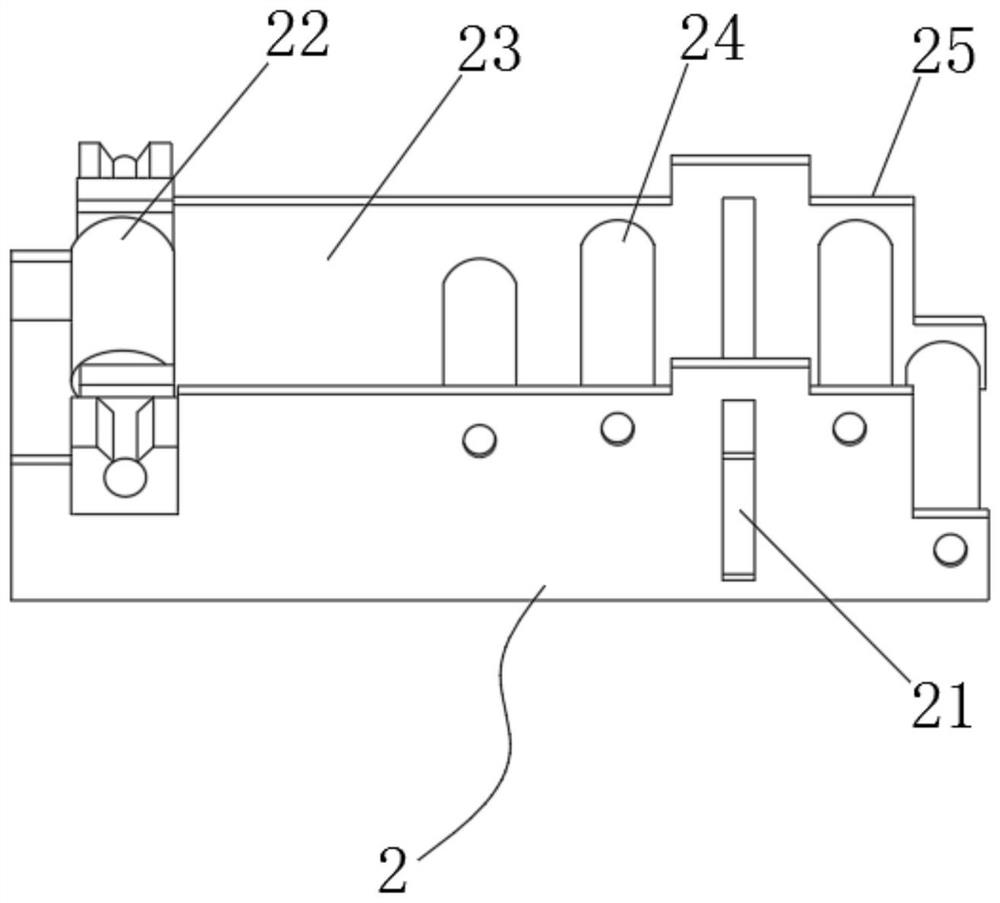

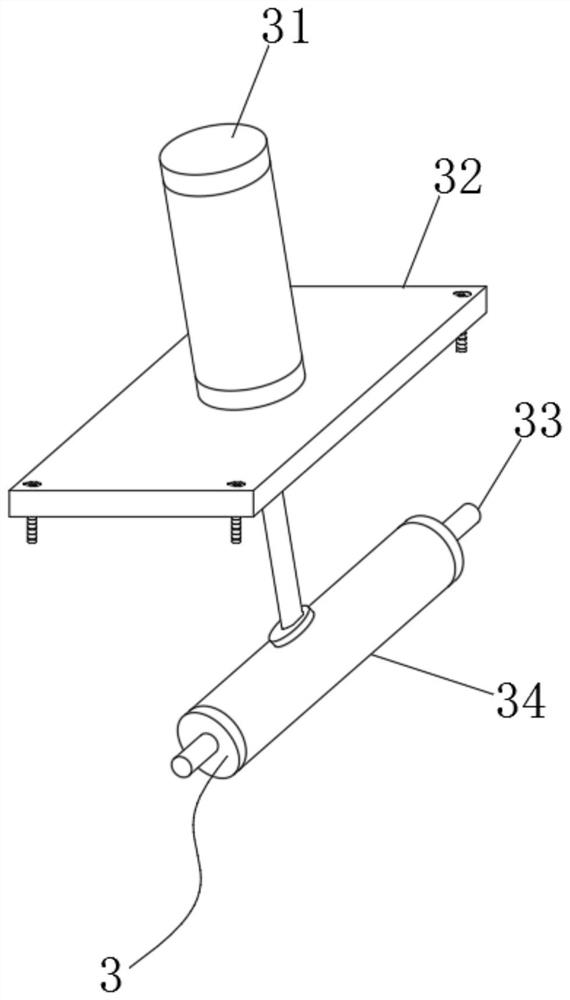

[0037] see Figure 1-Figure 3, the present invention provides a technical solution: a fully automatic mouth cap sealing film system, comprising a bottom metal frame 1 and a discharge film frame 2, the discharge film frame 2 is installed and fixed on the upper left side of the bottom metal frame 1, and the discharge The inside of the right end of the film frame 2 is provided with an adjustment presser 3, and the right side of the unwinding film frame 2 is located at the bottom. The metal frame 1 is provided with a first limit roller frame 4, and the right side of the first limit roller frame 4 is located at the bottom. The metal frame 1 is provided with a second limit roller frame 5, and the right side of the second limit roller frame 5 is located at the bottom. The metal frame 1 is provided with a mouth cover sealer 6, and the right side of the mouth cover film sealer 6 is located at the bottom. The metal frame 1 is provided with a third limit roller frame 7, the right side of...

Embodiment 2

[0041] Such as figure 1 , Figure 4 with Figure 5 , the first limit roller stand 4 includes a movable block 41, a small cylinder 42, a limit adjustment frame 43, an upper side round roller 44 and a fixed round roller 45, and the inner side of the bottom end of the limit adjustment frame 43 is provided with a fixed round roller 45, The grooves on both sides of the limit adjustment frame 43 are provided with movable squares 41, between the two movable squares 41, upper side round rollers 44 are arranged above the fixed round rollers 45, and the upper end of the movable squares 41 is provided with small-sized cylinders 42. The position adjustment frame 43 is installed and connected on the bottom metal frame 1, and the limit adjustment frame 43 of the first limit roller frame 4 is welded and installed on the bottom metal frame 1, so that the limit adjustment frame 43 is convenient for stable adjustment. When in use, Due to the small cylinder 42 on the upper end of the limit adj...

Embodiment 3

[0044] Such as figure 1 , Image 6 with Figure 7 The mouth cover sealer 6 includes a film sealing end 61, a film sealing cylinder 62, a limit frame 63, a side opening 64 and a mouth cover cover seat 65, and the inside of both ends of the limit frame 63 is provided with a side opening 64, The middle of the upper end of the limit frame 63 is provided with a sealing film cylinder 62, the lower end of the telescopic rod of the sealing film cylinder 62 is provided with a sealing film terminal 61, and the vertical lower part of the sealing film terminal 61 is provided with a mouth cover sleeve seat 65, and the mouth cover cover seat 65 and the limit frame 63 are installed and connected on the bottom metal frame 1, and the limit frame 63 of the mouth cover film sealer 6 is welded and installed on the bottom metal frame 1, so that the limit frame 63 is convenient for stable support and use, and the limit frame 63 Because of the area of the side opening 64, the film is convenient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com