Large thread automatic assembling equipment and assembling method

An automatic assembly and threading technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low assembly accuracy, inability to guarantee the screwing depth of the thread, etc., and achieve the effect of consistent depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

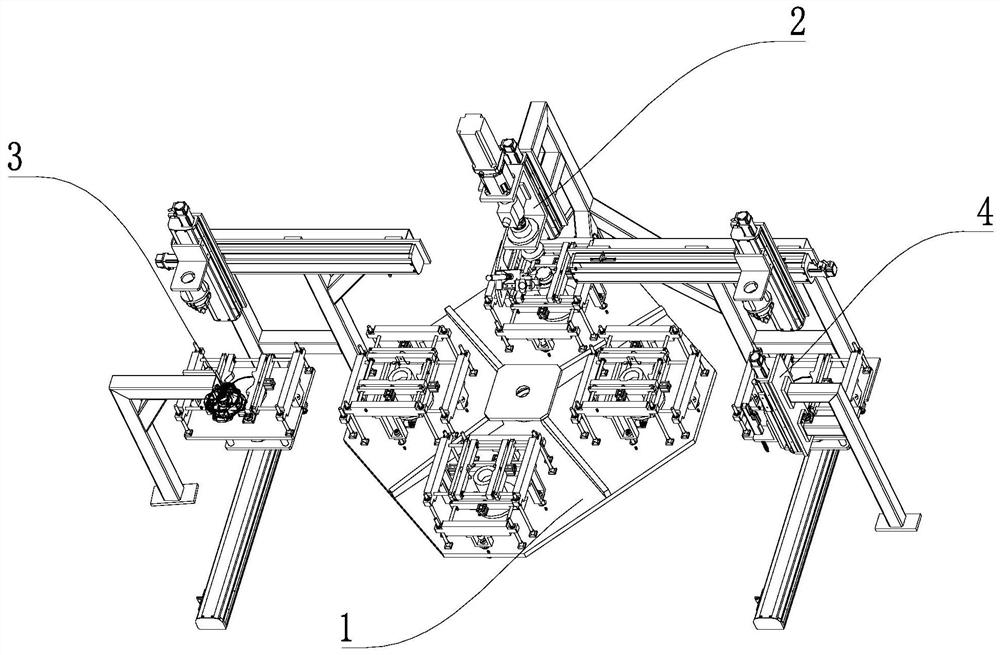

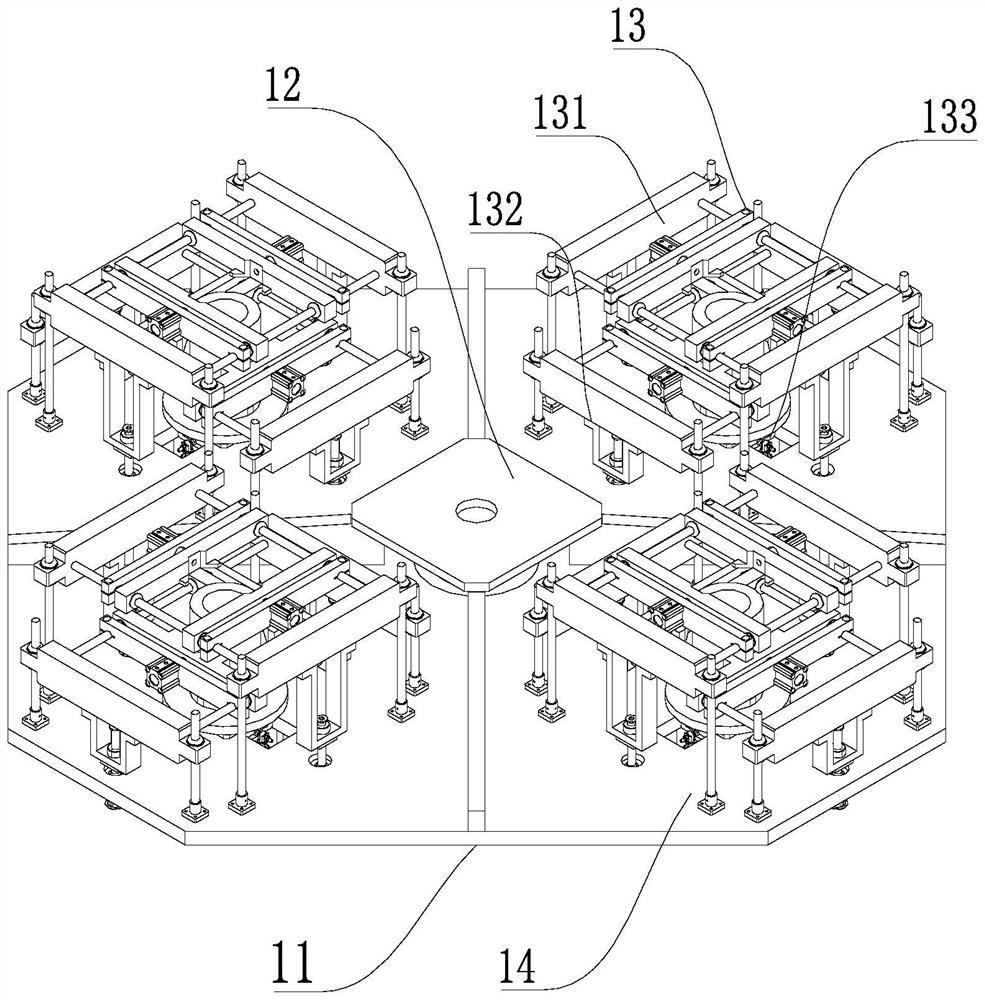

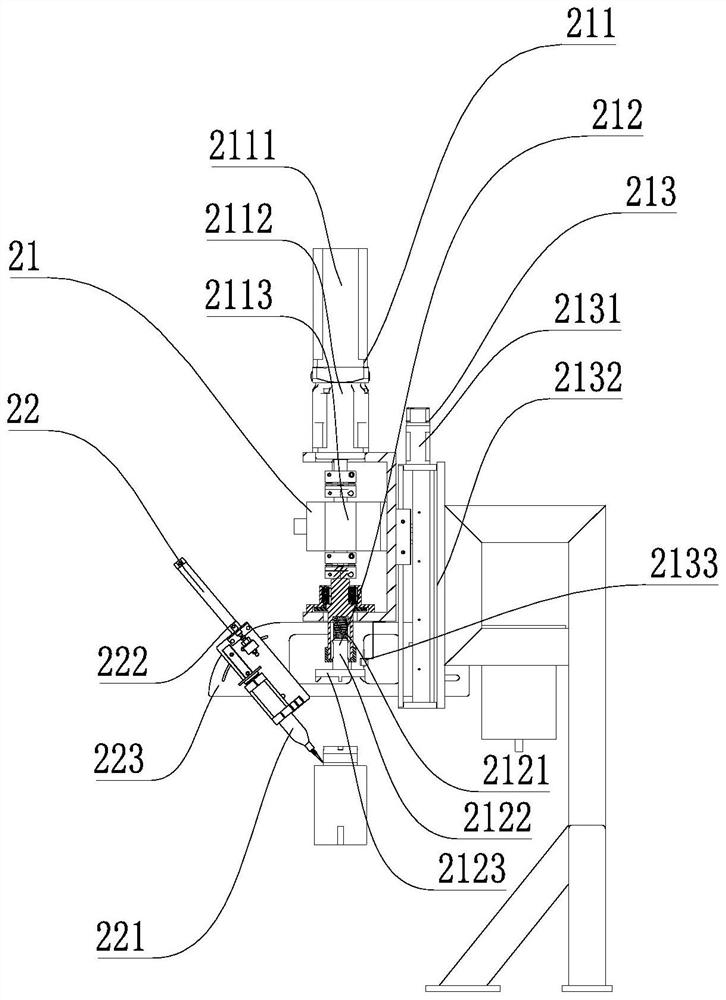

[0035] refer to Figure 1 to Figure 2 As shown, it includes a turntable device 1 , a gluing and tightening device 2 , a visual deviation correction device 3 and a depth detection device 4 .

[0036] Specifically, the turntable device 1 includes a turntable 11 provided with a plurality of stations 14 and a turntable drive mechanism 12. The turntable drive mechanism 12 is connected to the turntable, and the turntable drive mechanism 12 is used to drive the turntable 11 to rotate. A plurality of parts positioning fixtures 13 for the base and external threads, and the plurality of parts positioning fixtures 13 are arranged in cooperation with a plurality of stations 14 on the turntable 11. material station; the gluing and tightening device 2 is set on the side of the gluing and tightening station, which is used for gluing the external thread and tightening the external thread and the internal thread base; the visual deviation correction device 3 is set on the side of the external ...

specific Embodiment 2

[0057] The difference between the large thread automatic assembly equipment in this embodiment and the above-mentioned specific embodiment 1 is that the turntable 11 in this embodiment is divided into four stations at equal intervals: the inner thread base feeding station, the outer thread feeding station, Glue tightening station and finished product unloading station.

[0058] Large screw thread automatic assembly method of the present invention:

[0059] 1) The manipulator takes out the internal thread base from the feeding tray, places it on the part positioning fixture 13 of the turntable 11, cooperates with the internal thread base positioning clamping mechanism 132 and the second quick-change chuck 133, and places the internal thread base on Centering and clamping; the manipulator takes out the external thread from the feeding tray and places it on the micro-motion platform 33 of the visual deviation correction device 3, the centering clamping mechanism 32 centers the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com