System and method for detecting service life of filter element of water purifier

A filter life, water purifier technology, applied in chemical instruments and methods, osmosis/dialysis water/sewage treatment, semi-permeable membrane separation, etc., can solve the problems of filter clogging, differences in use, and filter life differences, etc. , to achieve the effect of avoiding waste and utilizing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

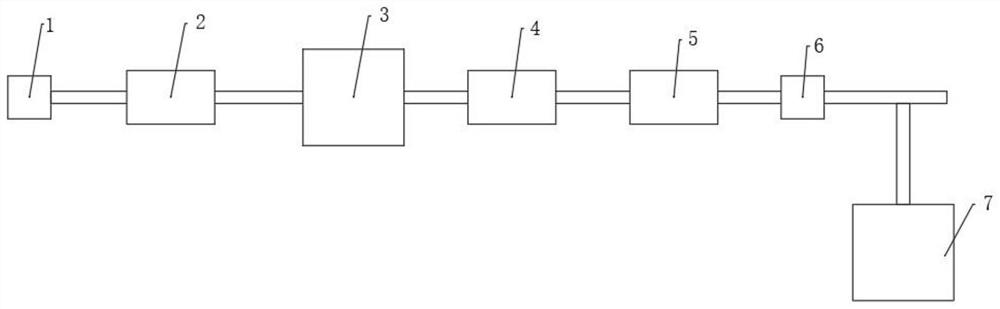

[0036] Such as Figure 1-3 As shown, the embodiment of the present invention provides a system for detecting the life of a filter element of a water purifier. The system includes a low pressure switch 1, a filter membrane device 2, a booster pump 3, an RO reverse osmosis membrane device 4, a flow meter 5, a high pressure switch 6 and Pressure tank 7, low pressure switch 1, filter membrane device 2, booster pump 3, RO reverse osmosis membrane device 4, flow meter 5, high pressure switch 6 and pressure tank 7 are connected through pipelines in sequence;

[0037] The low-pressure switch 1 is used for water shortage protection of the whole machine. When the tap water pressure reaches the set value, the low-pressure switch 1 is closed, the water making circuit is connected, and the pure water machine works normally. When the water is cut off or the water pressure is lower than the set value, the low-pressure switch 1 The switch 1 is disconnected, the water making circuit is cut off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com