Automatic Pu'er tea turning device

A technology for automatic turning and Pu-erh tea, applied in the direction of tea processing before extraction, can solve the problems of uneven turning, affecting temperature, humidity, air circulation, affecting the quality of tea fermentation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

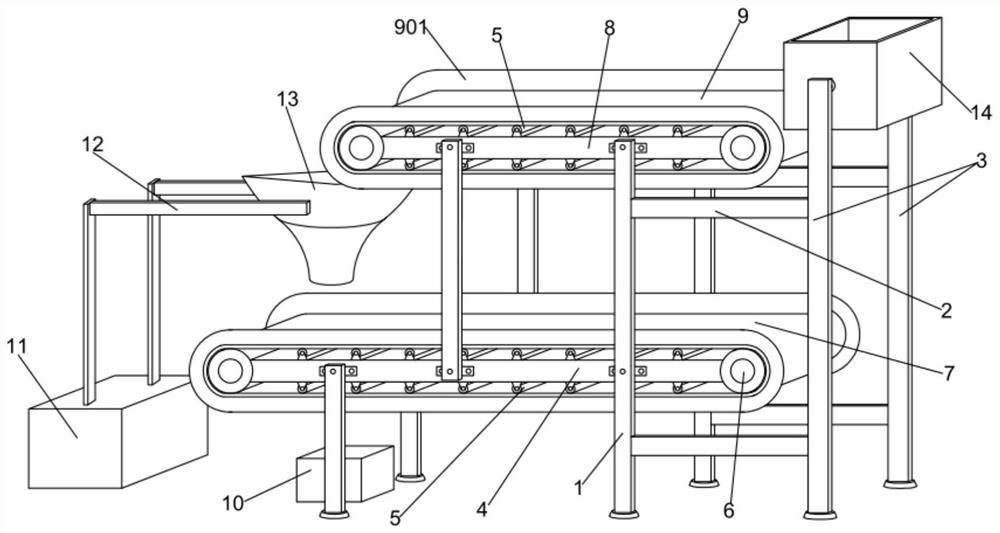

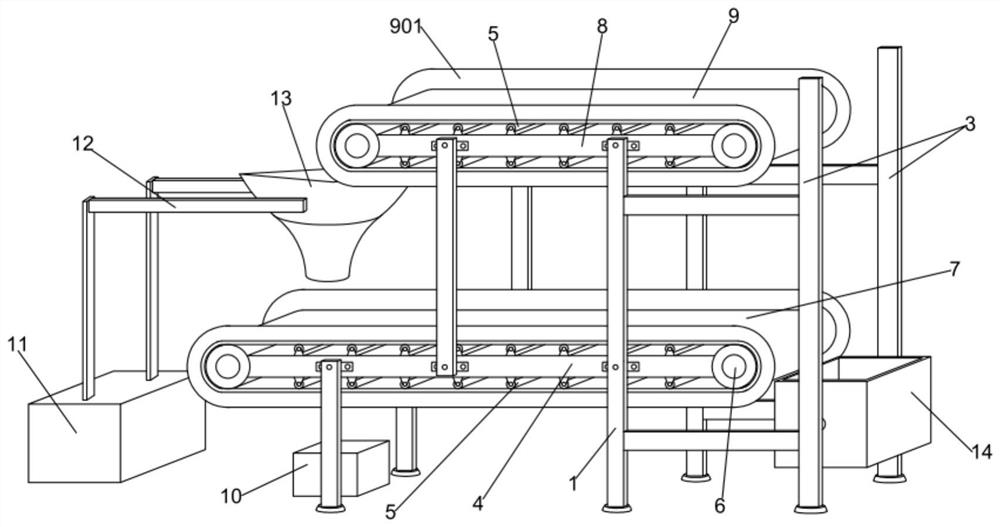

[0040] An automatic turning device for Pu'er tea, characterized in that it comprises: a vertical support bar 1, a horizontal bar 2, a transfer box support vertical bar 3, a lower conveyor belt disc 4, an auxiliary runner 5, a driving motor roller 6, a lower conveyor belt 7, Upper conveyor belt reel 8, upper conveyor belt 9, electromechanical module 10, dispersing frame base 11, dispersing frame 12, dispersing frame 13, transfer box 14;

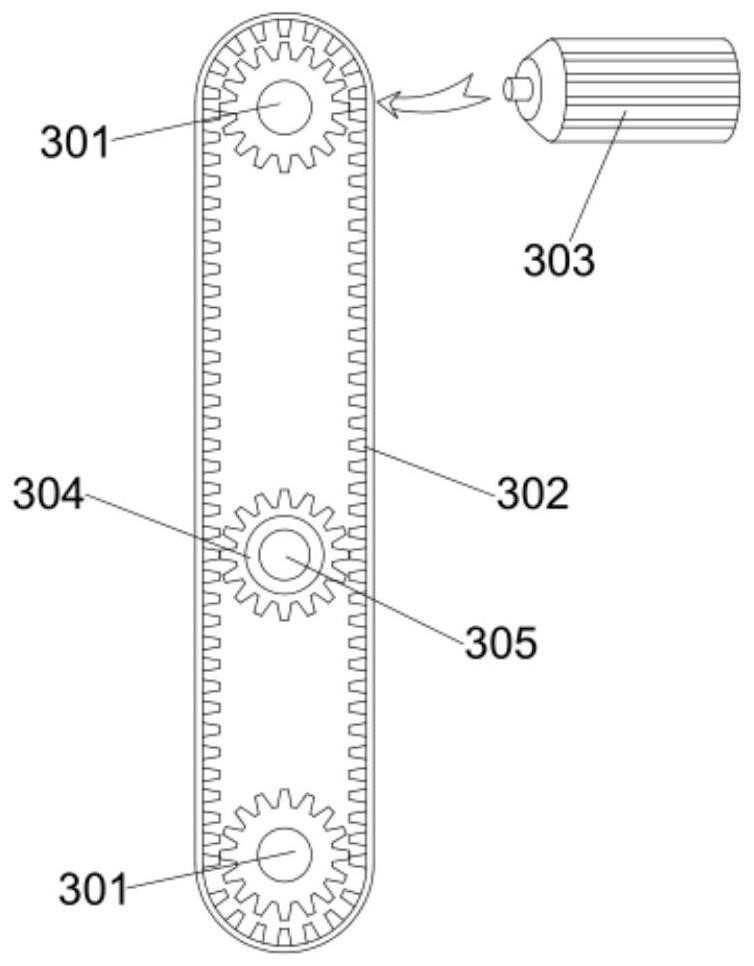

[0041] The transfer box support vertical bar 3 is connected to the horizontal bar 2 between the two longest vertical support bars 1, and the lower layer conveyor belt is fixedly connected between the two longest vertical support bars 1 and the two shortest vertical support bars 1 4. The upper and lower sides of the lower conveyor belt reel 4 are evenly connected with auxiliary runners 5, and each of the two ends of the lower conveyor belt reel 4 is connected with a drive motor roller 6; the drive motor roller 6 and the auxiliary runner 5 are co...

Embodiment 2

[0048] An automatic turning device for Pu'er tea, characterized in that it comprises: a vertical support bar 1, a horizontal bar 2, a transfer box support vertical bar 3, a lower conveyor belt disc 4, an auxiliary runner 5, a driving motor roller 6, a lower conveyor belt 7, Upper conveyor belt reel 8, upper conveyor belt 9, electromechanical module 10, dispersing frame base 11, dispersing frame 12, dispersing frame 13, transfer box 14;

[0049] The transfer box support vertical bar 3 is connected to the horizontal bar 2 between the two longest vertical support bars 1, and the lower layer conveyor belt is fixedly connected between the two longest vertical support bars 1 and the two shortest vertical support bars 1 4. The upper and lower sides of the lower conveyor belt reel 4 are evenly connected with auxiliary runners 5, and each of the two ends of the lower conveyor belt reel 4 is connected with a drive motor roller 6; the drive motor roller 6 and the auxiliary runner 5 are co...

Embodiment 3

[0056] Based on the structure of Example 1, when the tea leaves are transported on the conveyor belt, the tea leaves are prevented from spilling from the sides of the conveyor belt due to the side stop; absorbent layer for absorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com