Linear motor performance test method

A technology of linear motors and testing methods, applied in the direction of motor generator testing, machine/structural component testing, measuring devices, etc., can solve problems such as the inability to realize the correct use of linear motors and the inability to fully obtain the performance of linear motors, and achieve cost performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In order to set forth the technical content of the present invention more clearly, it will be described in detail in conjunction with specific examples and accompanying drawings. Obviously, the examples listed are only preferred implementations of the technical solution, and those skilled in the art can Other technical solutions obtained obviously from the content still belong to the protection scope of the present invention.

[0048] In the embodiment of the present invention, the linear motor is subjected to the following four tests: back electromotive force waveform detection, locked-rotor test, no-load test and thrust wave test.

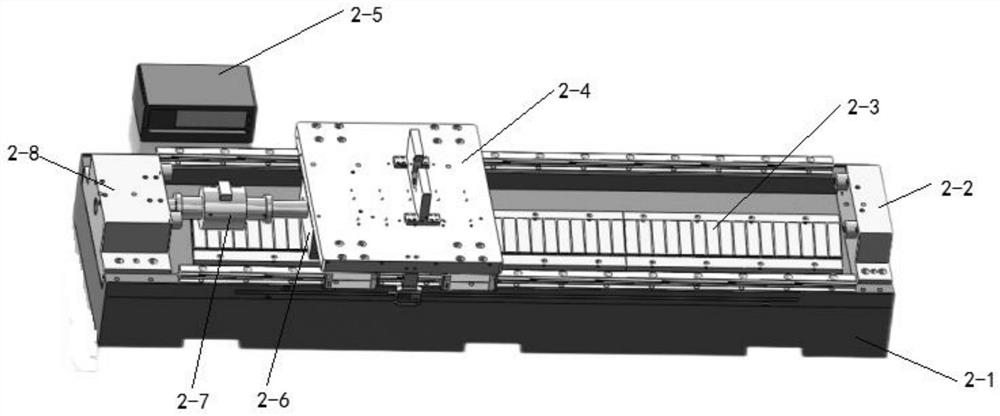

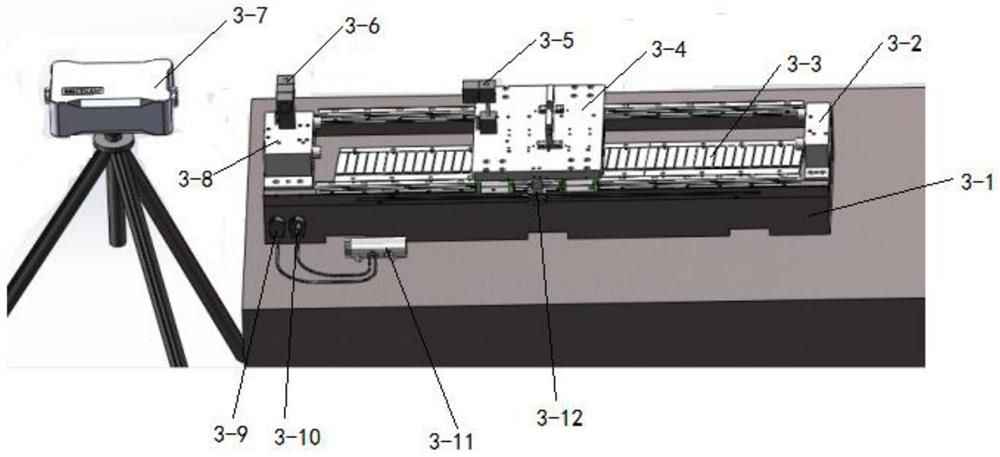

[0049] According to attached figure 1 Assemble the back electromotive force waveform test device to assemble the test device, specifically including the first linear motor, oscilloscope 1-7, screw rod 1-3, force sensor 1-4, first slide table 1-5, first base 1- 1. The first magnetic plate 1-2 and the auxiliary motor 1-6; the oscilloscope 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com