Method for jointly treating open pit through waste rocks and dry tailings

An open pit and dry tail technology, applied in safety devices, mining devices, earthwork drilling and other directions, can solve problems such as secondary disasters on open slopes, and achieve the effects of optimizing resources, reducing environmental damage and avoiding safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

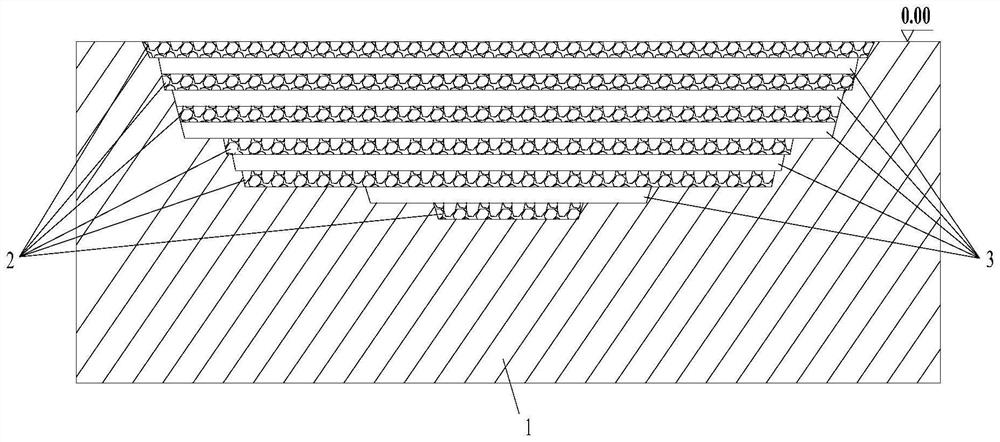

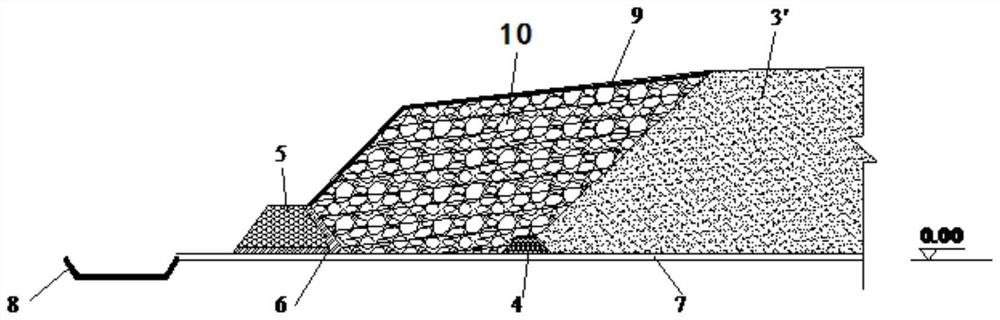

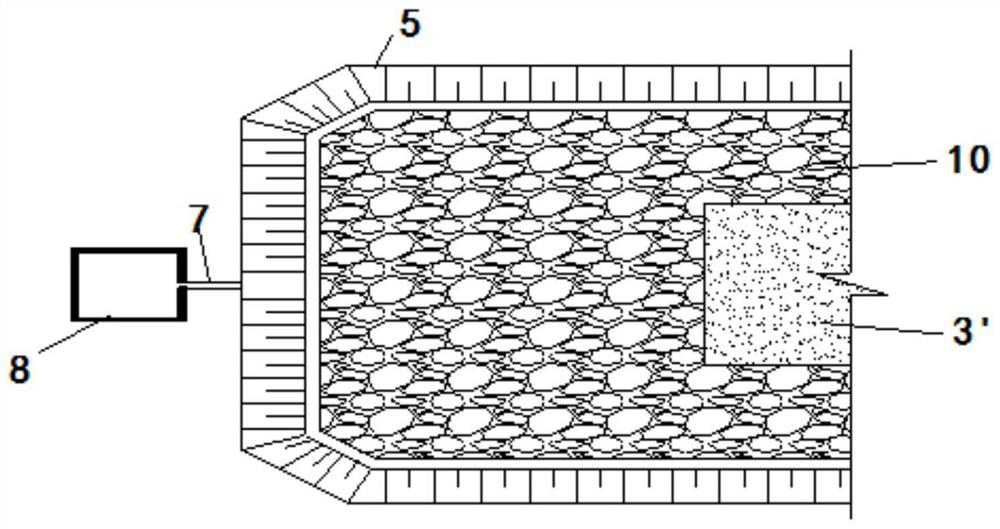

[0056] Taking the deep concave open pit as an example, the elevation of the closed circle on the surface is set to 0m. In the first phase of the disposal project, the bottom and slope of the open pit are cleaned first, and the hydraulic channels connecting the open pit and groundwater are blocked to prevent the backfill from polluting the underground and the water in the surrounding surrounding rocks.

[0057] Such as figure 1As shown, the waste rock 2 is discharged to the bottom of the open pit by a car or a belt conveyor, and a 5-8m thick waste rock layer is formed after being rolled by a road roller. Then, the dry tailings 3 after pressure filtration and dehydration are transported to the waste rock layer at the bottom by a belt conveyor and compacted to form a dry tailings layer, and the thickness of the dry tailings layer is controlled below 5m. Among them, the dry tailings 3 used for backfilling the open pit in the first phase of the disposal project is formed by dense ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com