Automatic control method and device for dust collection pipeline of drilling machine

A technology of automatic control device and vacuum tube, which is applied in the fields of printed circuit manufacturing, printed circuit, metal processing, etc., can solve problems such as equipment misstarting and failure, and achieve the effect of reducing errors and realizing dust collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

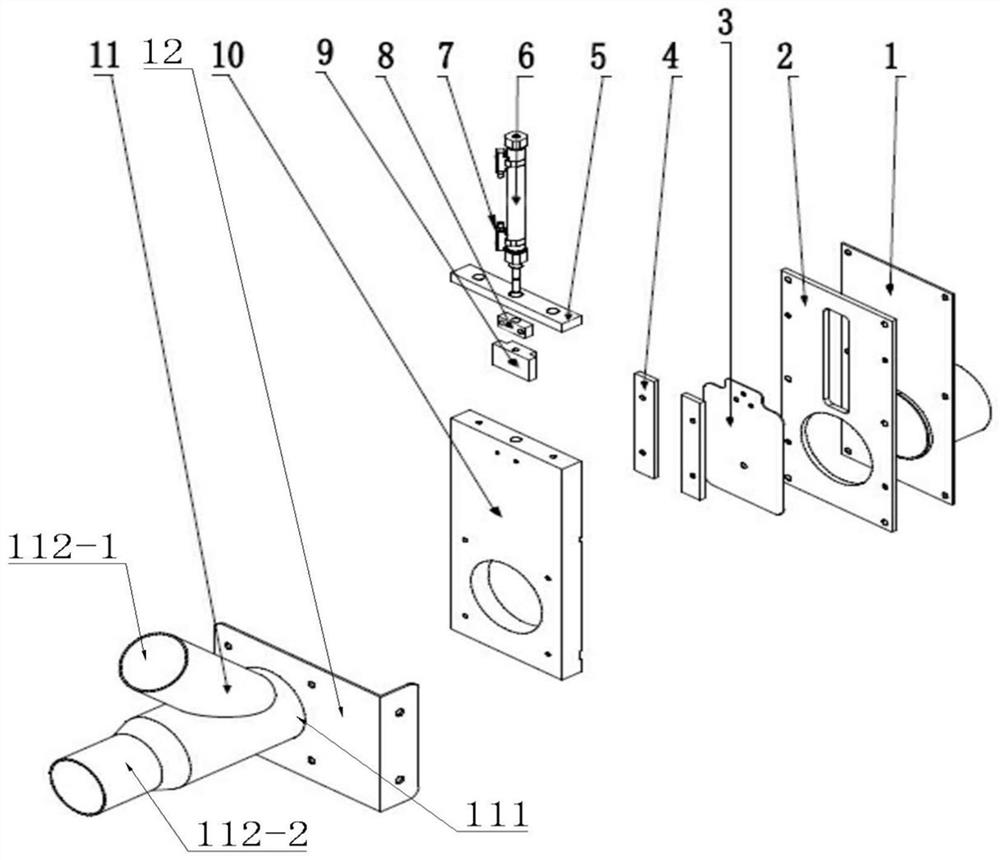

[0031] Now the present invention is further described in conjunction with description of drawings and embodiments:

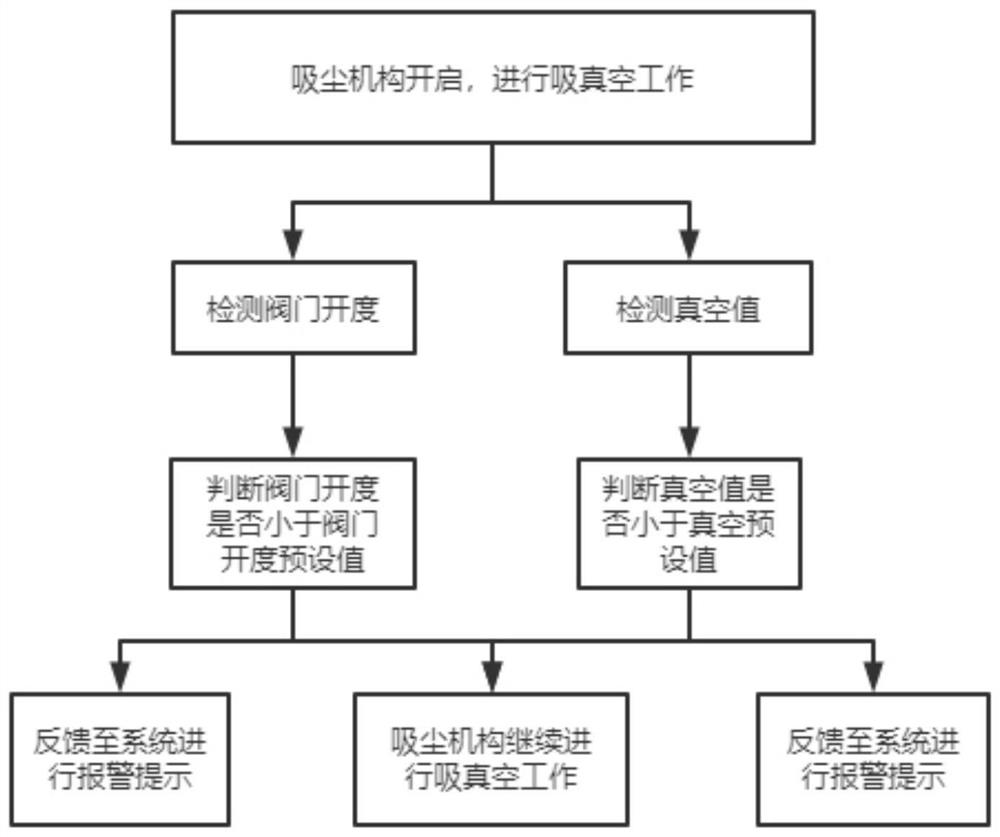

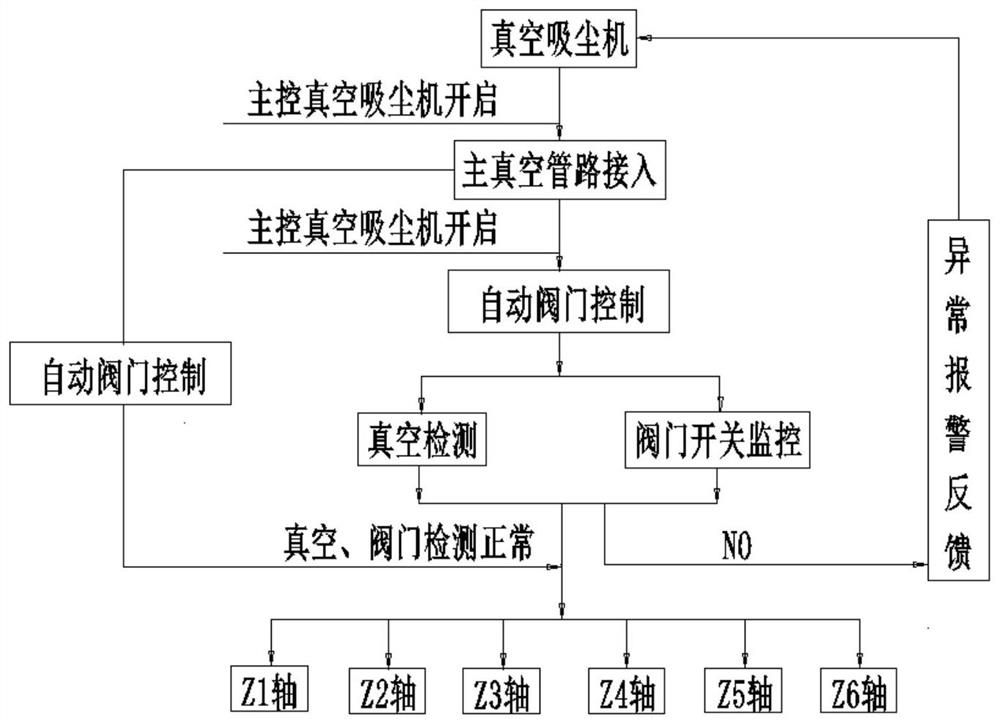

[0032] The present invention provides as attached Figure 1-2 A method for automatically controlling the vacuum pipeline of a drilling machine is shown, which includes:

[0033] The dust suction mechanism is controlled by monitoring the opening and closing of the valve to carry out the vacuum suction work, the vacuum degree is controlled by detecting and judging the vacuum value, and the automatic control device is used to centrally control several dust suction pipelines.

[0034] The present invention does not use a single dust-absorbing mechanism to vacuum a single drilling machine, but conducts long-term and centralized dust-absorbing work on several dust-absorbing pipelines through a centralized pipeline, and checks the opening and closing of the valve, the valve opening and The vacuum degree is detected and monitored and adjusted. The whole process is cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com