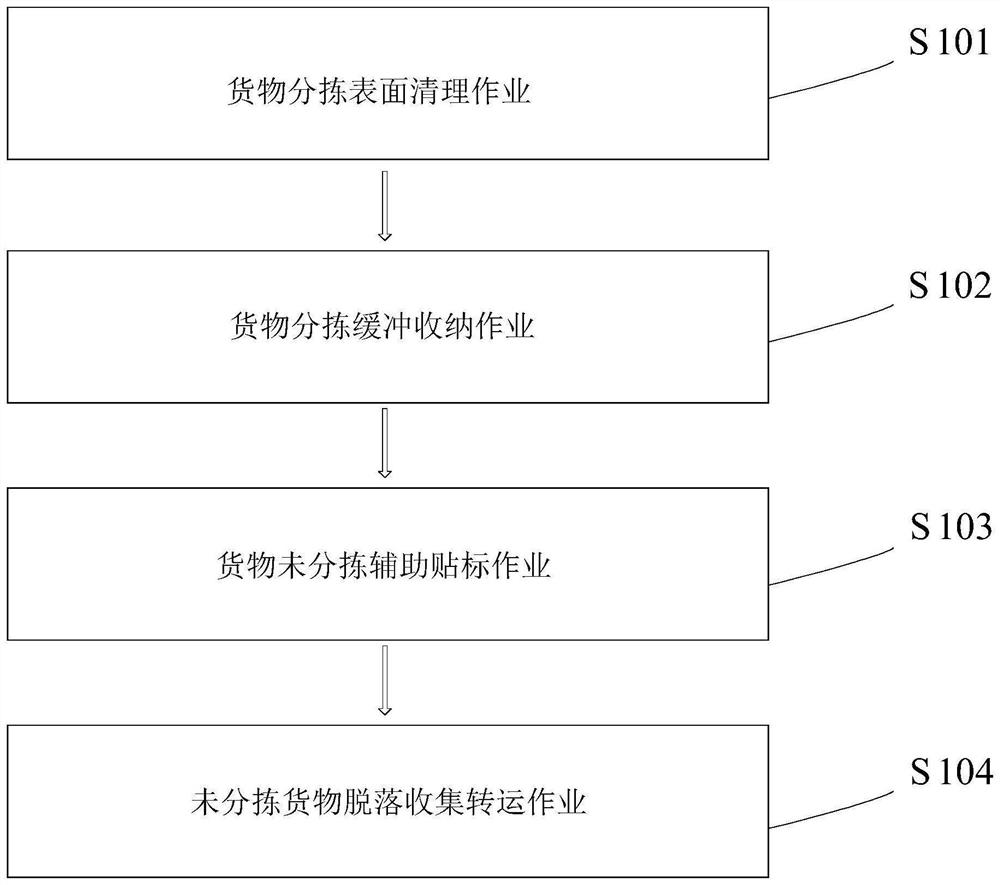

Full-automatic logistics sorting system and sorting method

A sorting system, fully automatic technology, applied in sorting, chemical instruments and methods, cleaning methods and utensils, etc., can solve the problems of affecting the sorting effect, inconvenient to collect fallen items, and not having the function of cleaning dust, etc. Ensure support stability, ensure sorting efficiency, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

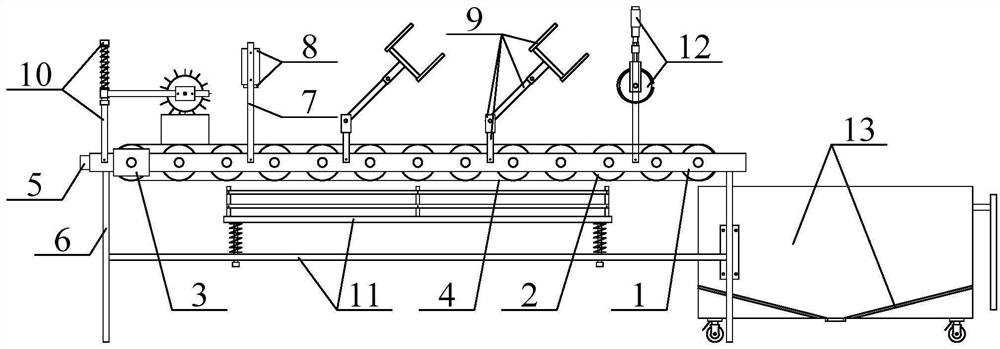

[0028] The present invention will be further described below in conjunction with accompanying drawing:

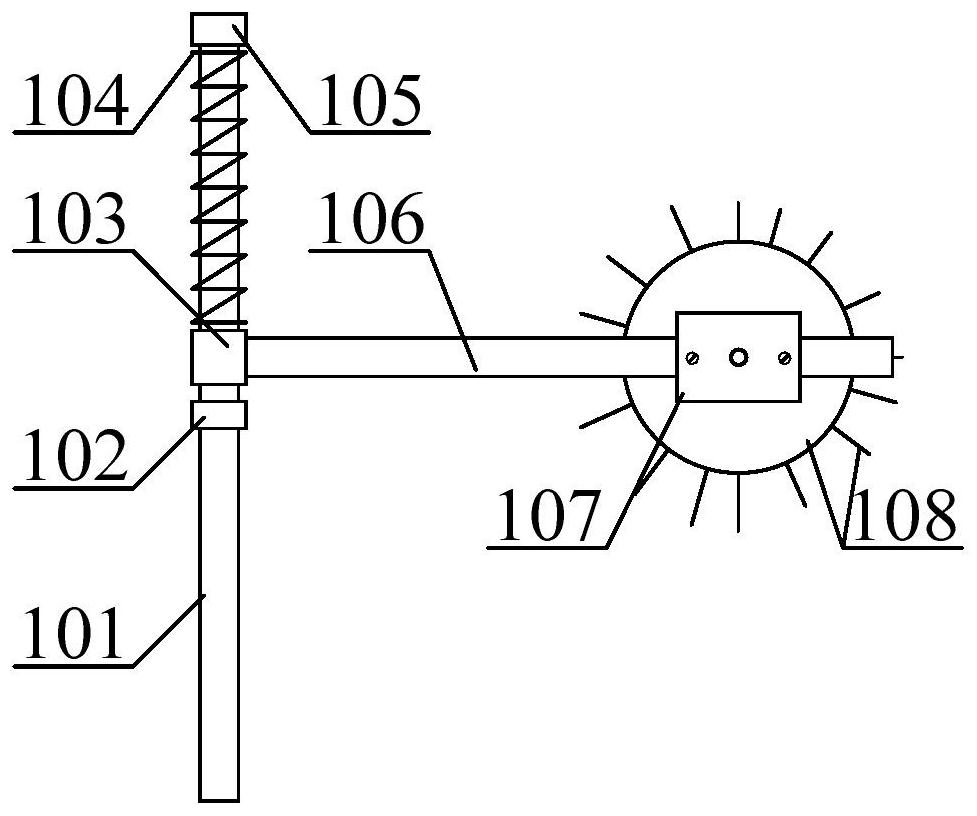

[0029] as attached figure 2 To attach Figure 6 As shown, the automatic logistics sorting system of the present invention includes a fully automatic logistics sorting system, including a sorting frame 1, a conveying wheel 2, a sorting conveying motor 3, a conveyor belt 4, a controller 5, and supporting legs 6. Support frame 7, high-definition sorting camera 8, electric sorting gripper 9, self-buffering cargo surface cleaning wheel structure 10, buffer protection frame structure 11 for sorting items, automatic labeling roller structure 12 and unsorted cargo falling off The collection box structure 13, the inside of the sorting frame 1 is pivotally connected with the conveying wheel 2 from left to right; the left side bolt of the front part of the sorting frame 1 is connected with the sorting and conveying motor 3; The output shaft of the sorting and conveying motor 3 runs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com