Rocker arm type sprayer and sprinkling irrigation method

A technology of rocker-arm sprinklers and rocker-arm shafts, which is applied in spraying devices, sprinkler devices with movable outlets, etc., can solve the problems of irrigation intensity and radial water distribution uniformity, and the variation of radial water distribution of rocker-arm sprinklers , Affecting crop yield and quality and other issues, to achieve the effect of improving the uniformity of sprinkler irrigation, good atomization level, and good wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

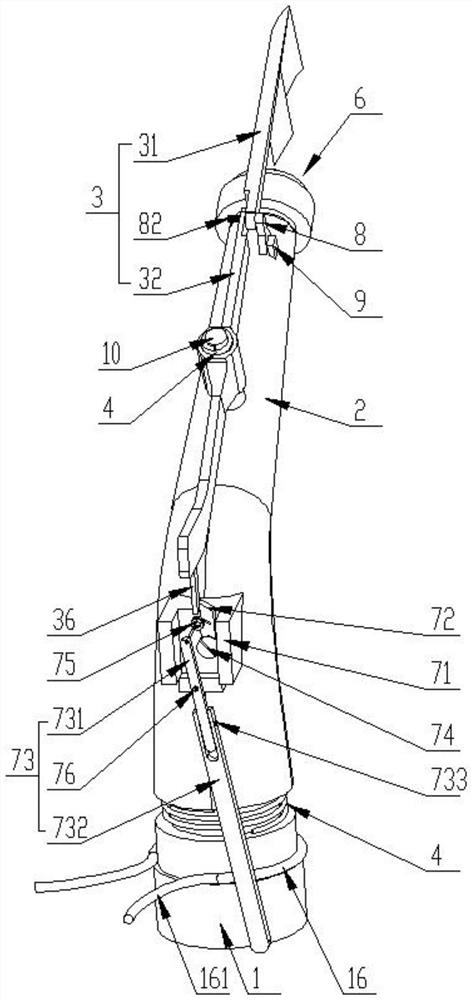

[0034] Figure 1-10 Shown is a preferred embodiment of the rocker spray head, the rocker spray head includes a hollow shaft 1, a nozzle 2, a rocker 3 and a rocker spring 4, the bottom of the nozzle 2 is connected to the hollow The shaft 1 is connected in rotation, the bottom of the spray pipe 2 side is provided with a sub-nozzle assembly 5, and the top end of the spray pipe 2 is provided with a main nozzle assembly 6 arranged on the same side as the sub-nozzle assembly 5, and the main nozzle assembly 6 and the sub-nozzle assembly 5 are both It includes a nozzle 561 that communicates with the nozzle 2 and can be rotated and adjusted relative to the nozzle 2;

[0035] The nozzle 2 is provided with a hit block 9 and a rocker shaft 10, and the rocker 3 includes a first arm 31 and a second arm 32 which can be adjusted and connected, and the rocker 3 is provided with the hit block 9. The impact block 8 with limited fit, the first arm 31 is provided with a deflector 33 and a deflect...

Embodiment 2

[0053] A sprinkling irrigation method, the method is to use the rocker type sprinkler head as described in the embodiment for sprinkling irrigation, adjust the elevation angle θ1 of the nozzle 561 of the main nozzle assembly 6 to 20°-35° according to the wind force and working pressure, and adjust the deflector plate 33 and the guide plate accordingly. The flow plate 34 corresponds to the main nozzle assembly 6 and adjusts the elevation angle of the nozzle 561 of the sub-nozzle assembly 5 .

[0054] Above-mentioned a kind of sprinkling irrigation method, preferably, specifically:

[0055] When the rocker sprinkler is at wind force ≤ 2 and rated working pressure -70% of the rated working pressure, adjust the elevation angle θ1 of the nozzle 561 of the main nozzle assembly 6 to 30°-35°, determine the elevation angle θ1 according to the maximum range, and reduce the sprinkling intensity. Simultaneously, in order to make the rocker arm 3 generate driving force, by adjusting the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com