Articulated system test method, system, medium and equipment

A technology of articulation system and test method, which is applied in the direction of elasticity test, vehicle test, design optimization/simulation, etc., can solve the problems of complex structure, no test method and high cost, so as to improve the test accuracy and improve the test accuracy. and test convenience, the effect of less input parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

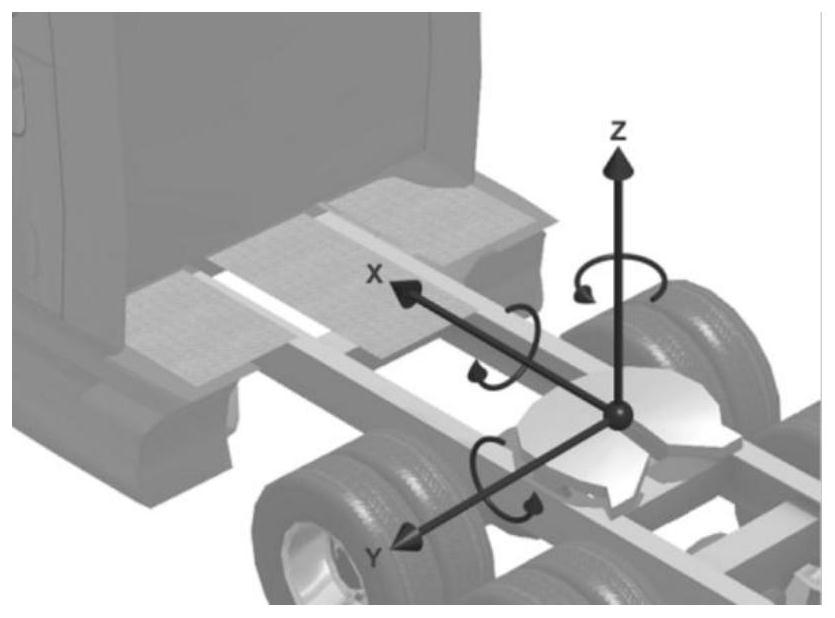

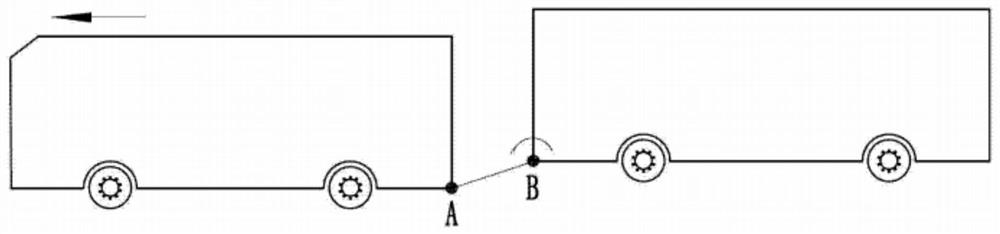

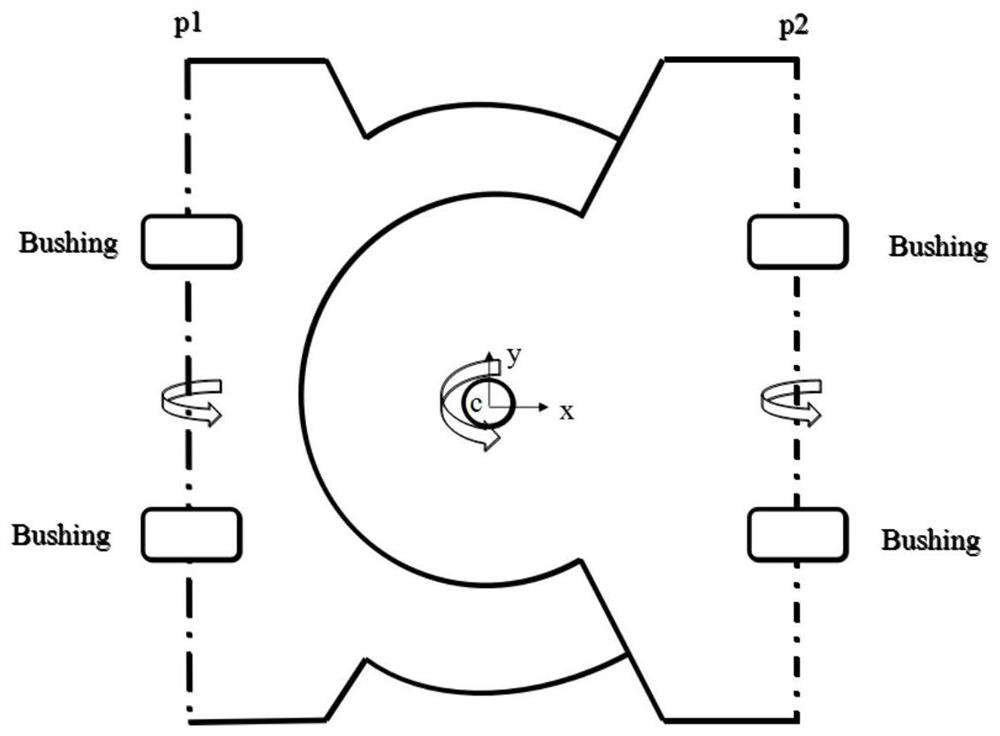

[0058] First of all, the structure of the hinge system of the present invention is as follows: Figure 3-4 As shown, an articulated vehicle with this articulation system such as Figure 5-6 shown. Figure 3-4 Medium P 1 ,P 2 represent V respectively 1 vehicle, V 2 The pitch axis of the vehicle relative to the articulated system, point c is the center of the yaw motion of the vehicle relative to the articulated system.

[0059] Such as Figure 10 As shown, the hinged system test method of the present embodiment comprises steps:

[0060] Establish a dynamic virtual test bench; where the dynamic virtual test bench includes V 1 vehicle, V 2 Vehicle body dynamics model and articulated system dynamics model;

[0061] Calculate the equivalent stiffness of the hinged system: failure of all subsystems related to damping characteristics in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com