Blanking screw sleeve hot drawing film forming square opening feeding structure

A technology of screw sleeve and hot drawing, which is applied in the direction of cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc., which can solve the problems of unsmooth feeding of powder materials and decreased measurement accuracy, so as to avoid clogging and ensure scraping The effect of removing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

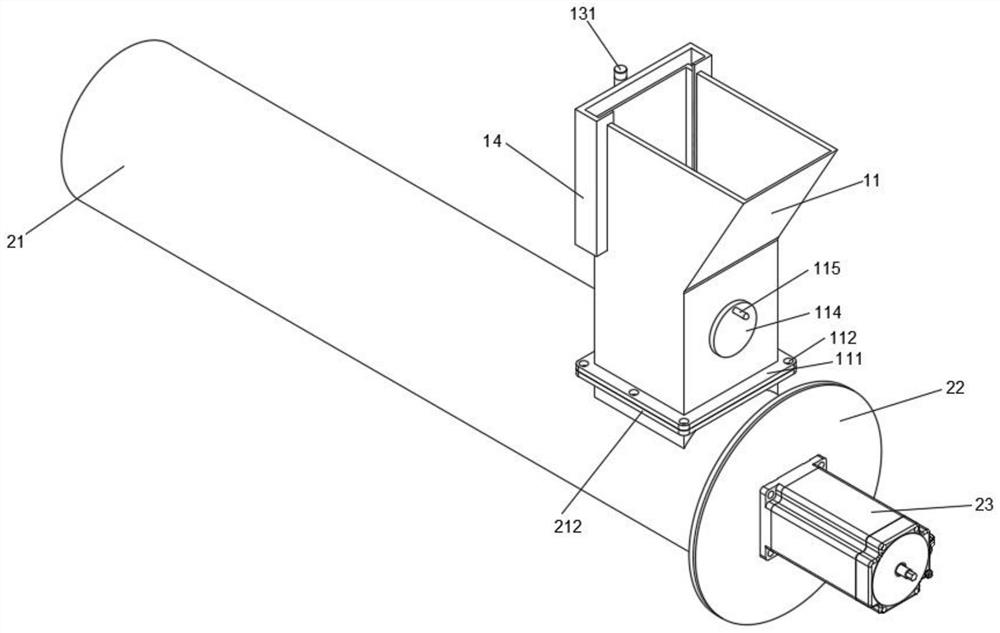

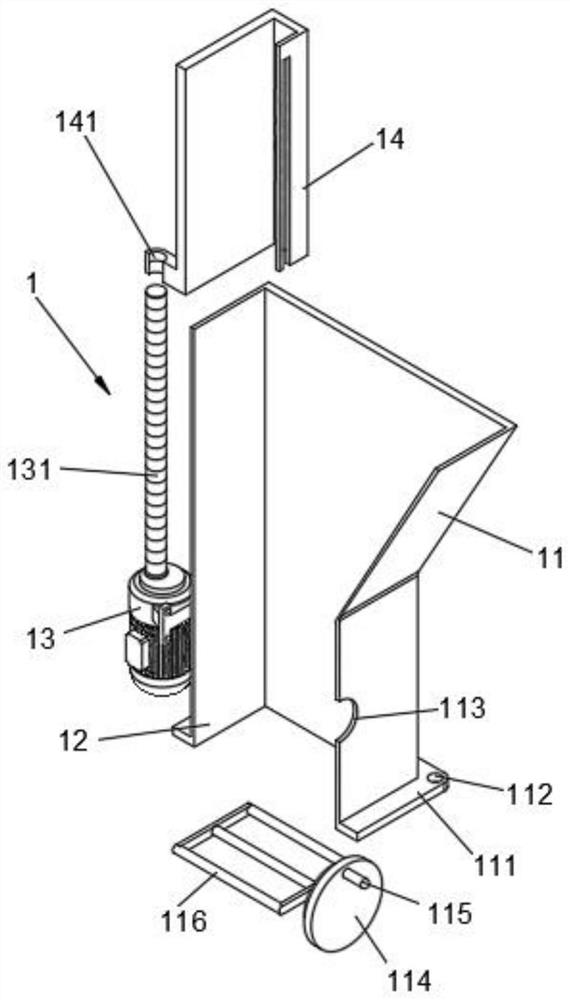

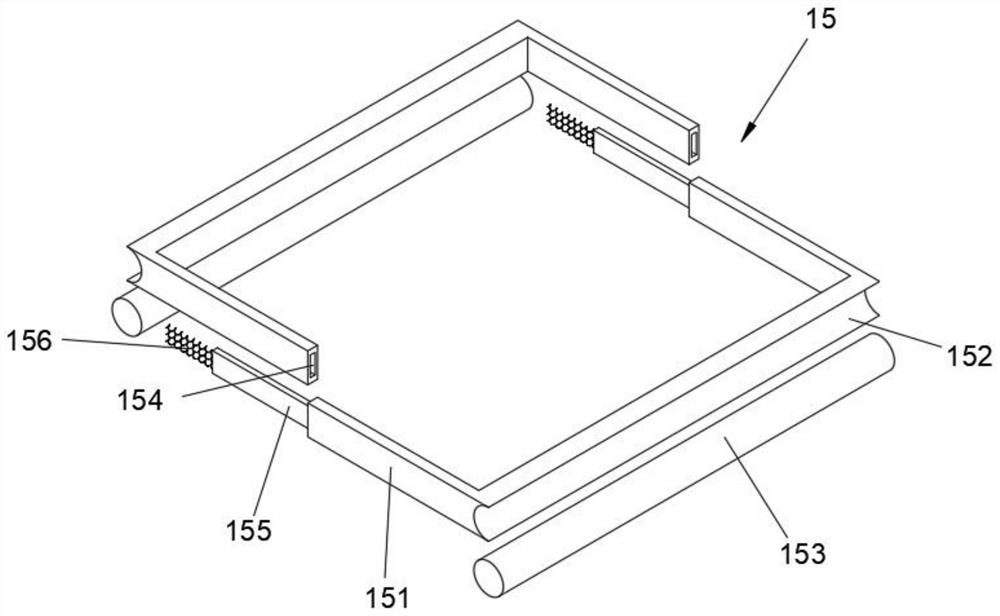

Embodiment 1

[0025] see Figure 1-Figure 4 As shown, this embodiment provides a feeding structure with a feeding screw sleeve hot-drawn film forming square opening, including a feed body 1 and a feed body 2 connected to the bottom of the feed body 1. The feed body 1 includes a hopper 11. Considering the traditional The material structure is prone to bridging phenomenon, which is not conducive to the discharge of powdery materials with small accumulation angle and poor flow rate. 12 is a square hole, and the feeding body 2 includes an outer cylinder 21 located at the bottom of the hopper 11. The outer cylinder 21 is provided with an outer opening 211, and the outer cylinder 21 is provided with an inner cylinder 22. The inner cylinder 22 is provided with an inner opening 222, and the inner opening 222 Located in the outer port 211, the top of the inner port 222 is connected to the bottom of the material port 12. By setting the connected material port 12 and the inner port 222, the material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com