High-position non-jacking beam falling construction method

A construction method and beam drop technology, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of long beam drop time and many support points, and achieve the effects of short drop time, reduced procedures, and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

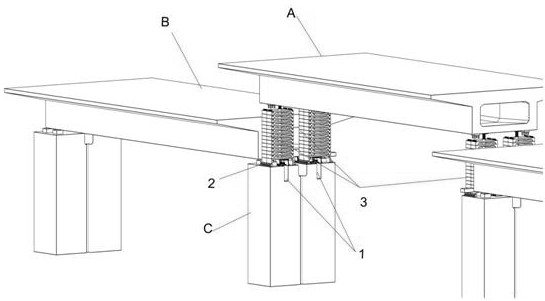

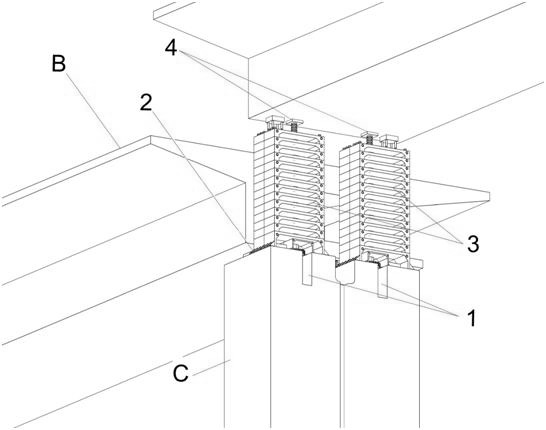

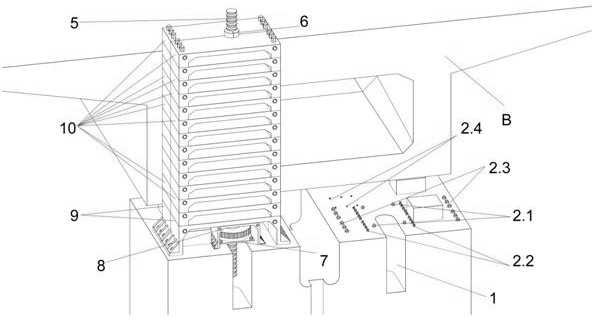

[0069] The structure of a high-level non-jacking and falling beam device is as follows:

[0070] as attached figure 1 ~ attached image 3 As shown, in the present invention, when pouring the pier C, the pier reserved groove 1 is placed directly below the support position of the box girder A to be dropped, the precision-rolled threaded steel system 2 is pre-embedded on the top surface of the pier C, and the box girder A to be dropped and Set up 4 sets of high-level falling beams without jacking up the falling beams device 3 between the piers C, pre-embed support plates at the bottom of the box girder 4, 4 sets of high-level falling beams without jacking up and falling beams devices 3 support the embedded support plates at the bottom of the box girder 4 below.

[0071] The pier reserved groove 1 is arranged on the inner side of the support pad, and the opening faces the other side of the poured beam section B, and the depth is greater than the segmental length of the set segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com