Wide-temperature-range multi-model bearing loading test platform

A test platform and multi-model technology, applied in the direction of mechanical bearing testing, etc., can solve problems such as the increase or decrease of the ambient temperature, the inability to meet the requirements of multiple models, and the complicated manual replacement of rotating shafts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] In order to make the purpose, content and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below.

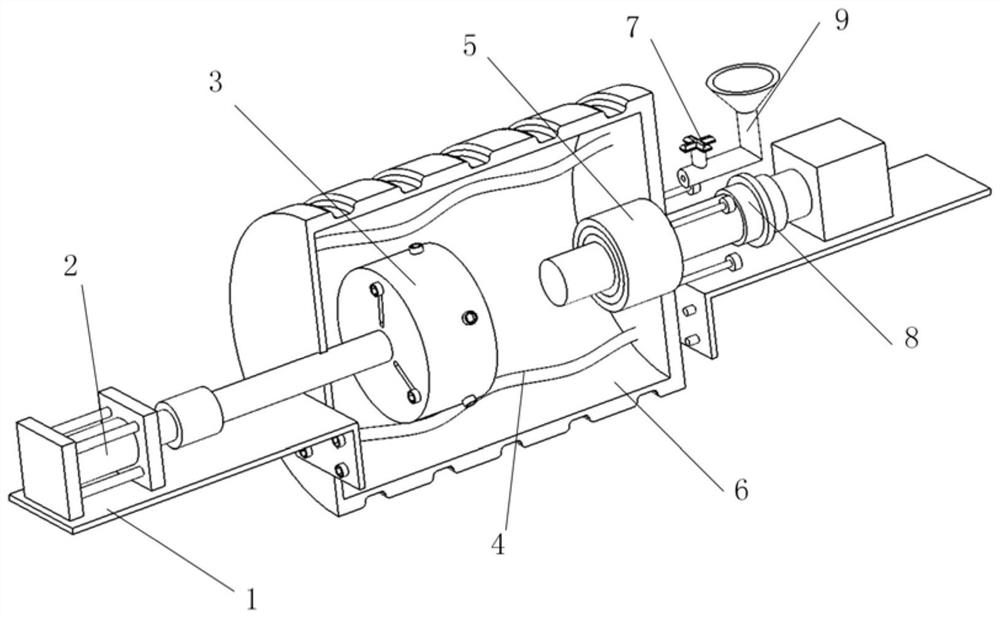

[0009] The invention proposes a multi-type bearing loading test platform in a wide temperature range, including a workbench 1, a bearing rotating device 2, a bearing outer ring fixing device 3, a bearing inner ring fixing device 5, a bearing system propulsion device 8; a bearing system propulsion device 8 and the bearing rotating device 2 are respectively fixed on the workbench 1, the bearing system propulsion device 8 is connected with the bearing inner ring fixing device 5 by a hydraulic cylinder, and the bearing system propulsion device 8 adopts the axial propulsion method of the hydraulic cylinder to realize axial movement and axial loading;

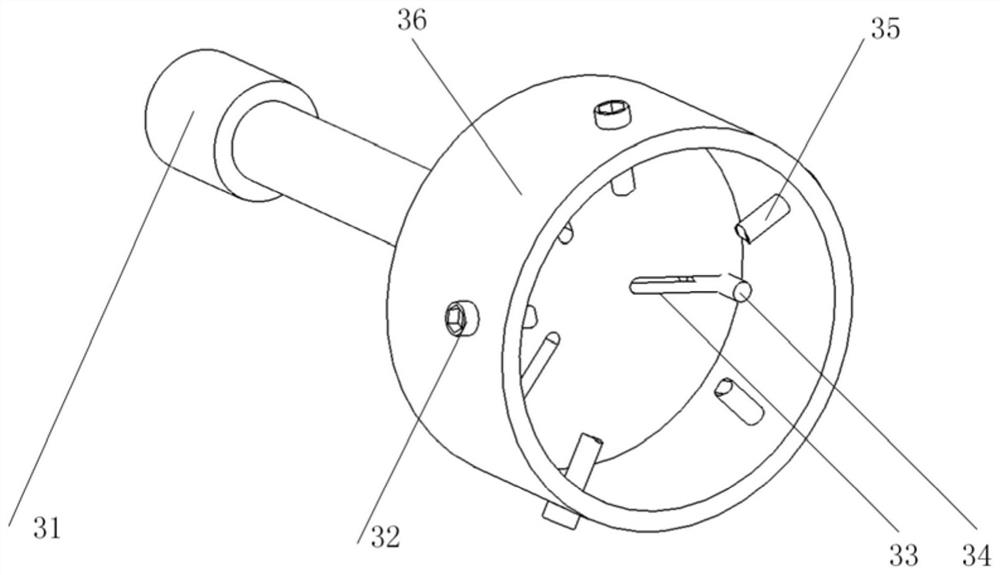

[0010] The bearing rotating device 2 is connected with one end of the bearing outer ring fixing device 3 to drive the bearing outer rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com