Flatness detection equipment for constructional engineering and use method of flatness detection equipment

A technology for flatness detection and construction engineering, applied in measuring devices, instruments, etc., can solve the problems of time-consuming, labor-intensive, inconvenient recording, low efficiency, etc., and achieve the effect of improving detection efficiency and reducing work burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

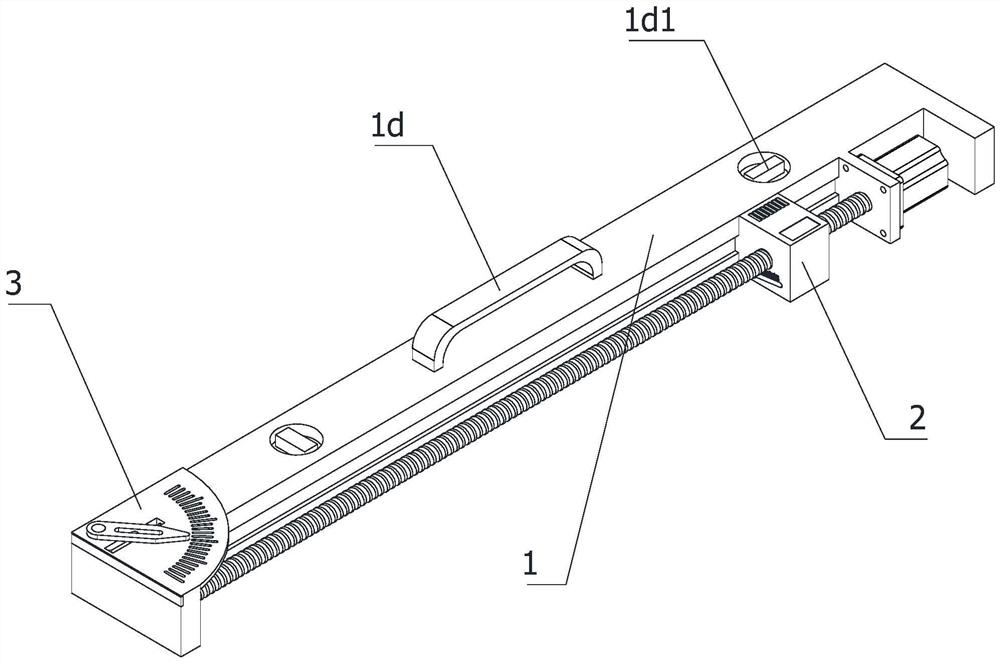

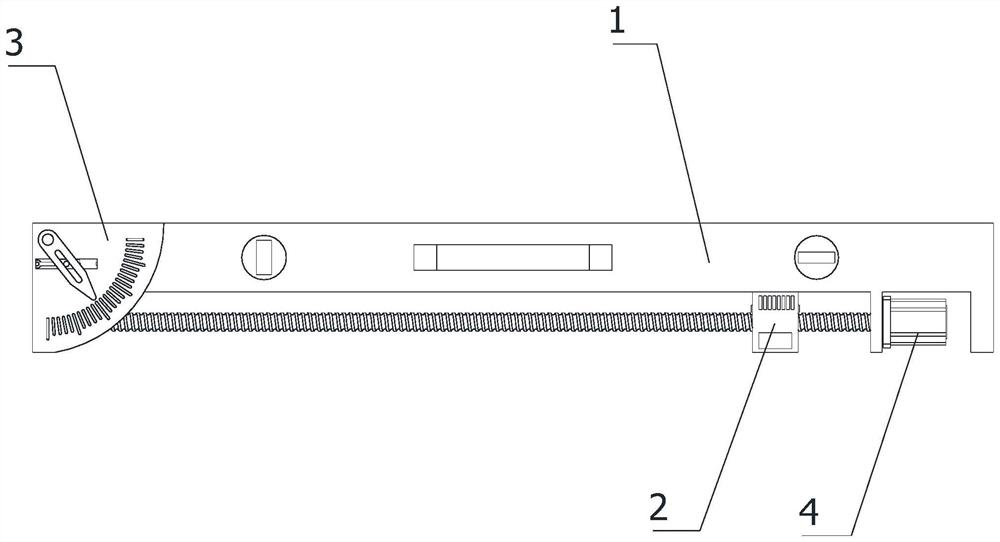

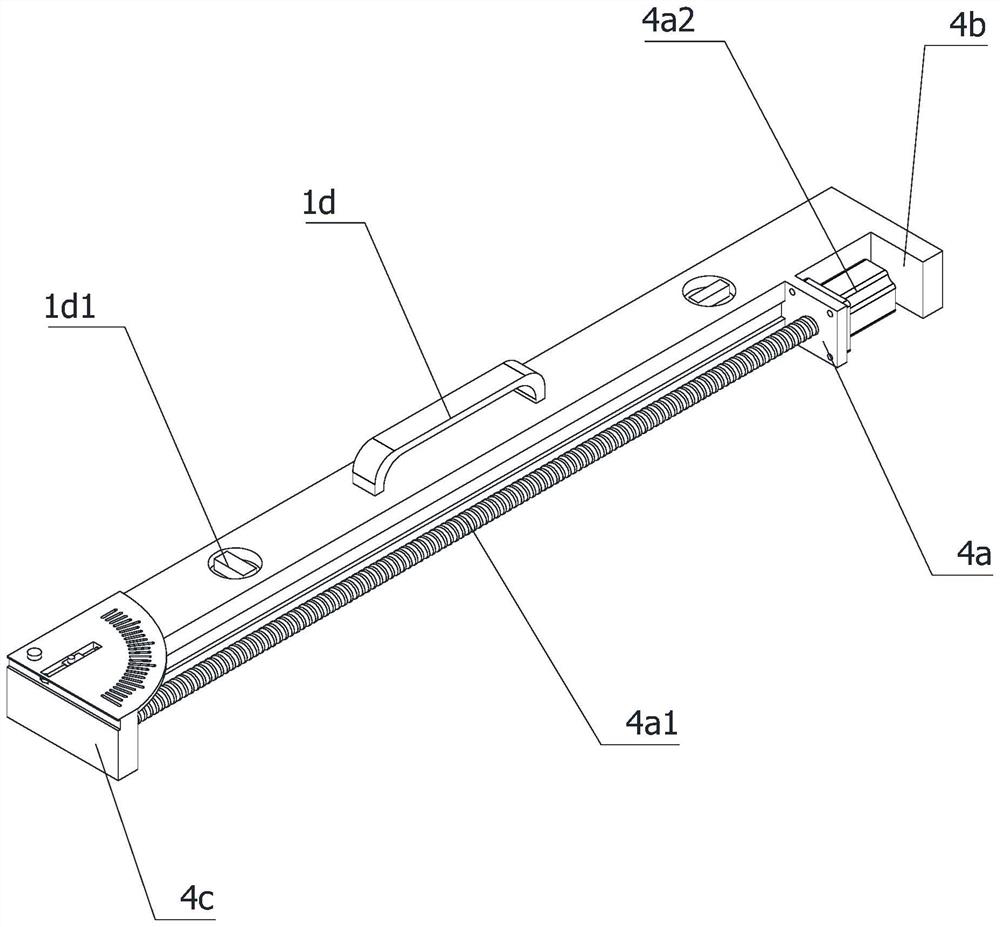

[0044] In order to further understand the features, technical means, and the specific purposes, functions achieved, which will be described in further detail below with reference to the accompanying drawings.

[0045] Such as Figure 1-12 Looking:

[0046] A planar detecting device for construction engineering, including measuring ruler 1 and a first measuring head 2 for measuring the planarity of the building wall or ground, and a first detection surface 1a is also provided on the measurement ruler 1. The second detection surface 1b, the first slide rail 1c, the first slide 3a and the second measuring head 3 for measuring the angle of the building wall or the ground, and the first detecting surface 1a is located at the bottom of the measuring ruler 1. The second detecting surface 1b is located one of the ends of the width direction of the measuring ruler 1, and the first slide rail 1c is disposed in the longitudinal direction of the measuring ruler 1, and the measuring ruler 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com