Fly ash working condition specific resistance on-line monitoring device and method

A monitoring device, a technology of specific resistance, which is applied in the direction of measurement device, measurement of resistance/reactance/impedance, measurement of electrical variables, etc., can solve the problems of inability to accurately measure specific resistance under working conditions, inability to realize online measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

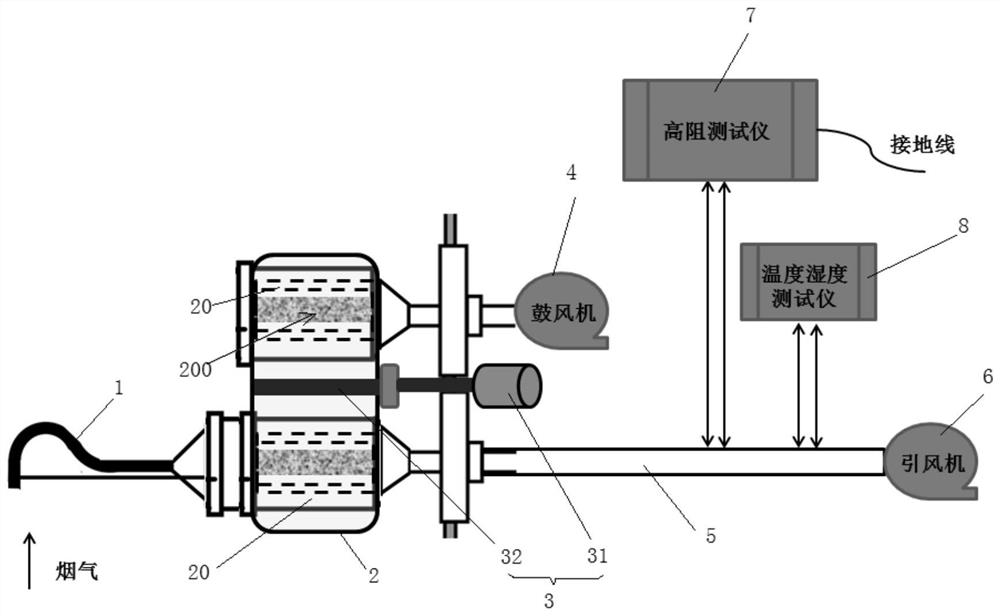

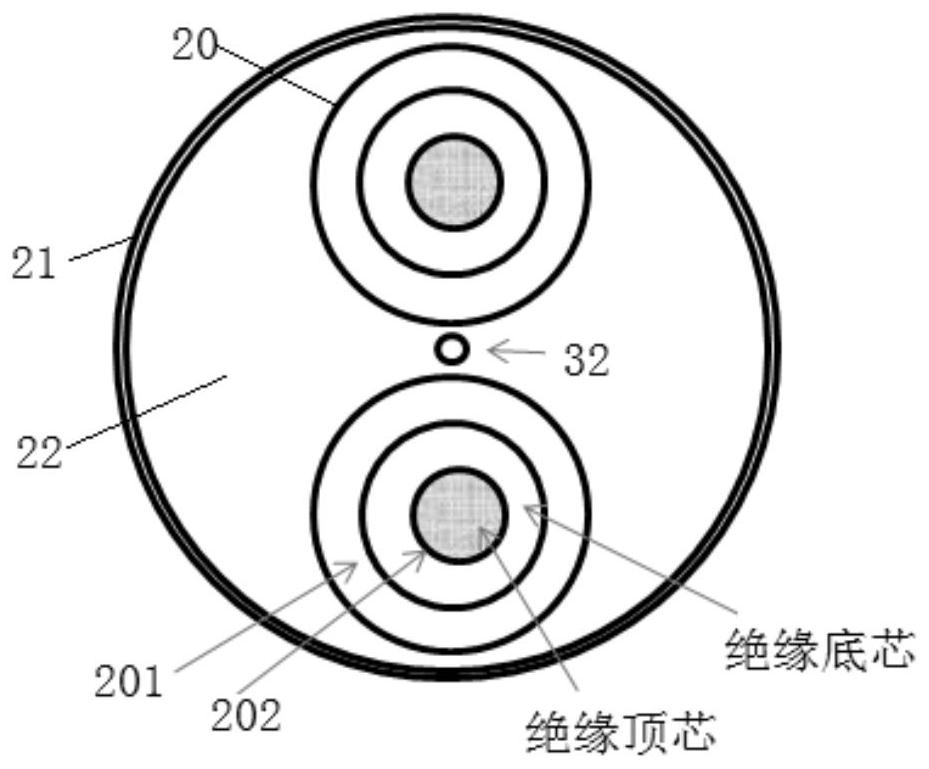

[0028] refer to Figure 1 to Figure 2 The present invention is an on-line monitoring device for specific resistance of fly ash working condition, which comprises intake elbow 1, fly ash collection bin 2, drive mechanism 3, blowback system 4, sampling gun 5, induced draft fan 6, high resistance tester 7 and A temperature and humidity tester 8, at least two movable electrodes 20 are arranged in the fly ash collection bin 2, and the drive mechanism 3 is connected to the fly ash collection bin 2 for driving each electrode in the fly ash collection bin 2. The position of the electrode 20 is switched, the first air intake end of the fly ash collection bin 2 is connected to the outlet of the intake elbow 1, the first air outlet end of the fly ash collection bin 2 is connected to the inlet of the sampling gun 5, and the outlet of the sampling gun 5 The outlet is connected to the induced draft fan 6, and the high-resistance tester 7 and the temperature and humidity tester 8 are all con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com