Vertical dryer capable of drying more uniformly

A vertical dryer, a uniform technology, applied in the direction of dryers, drying, partial agitation dryers, etc., can solve the problems of high moisture content of materials, affecting quality, leakage of materials, etc., to achieve uniform discharge volume, easy Precise control and improvement of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

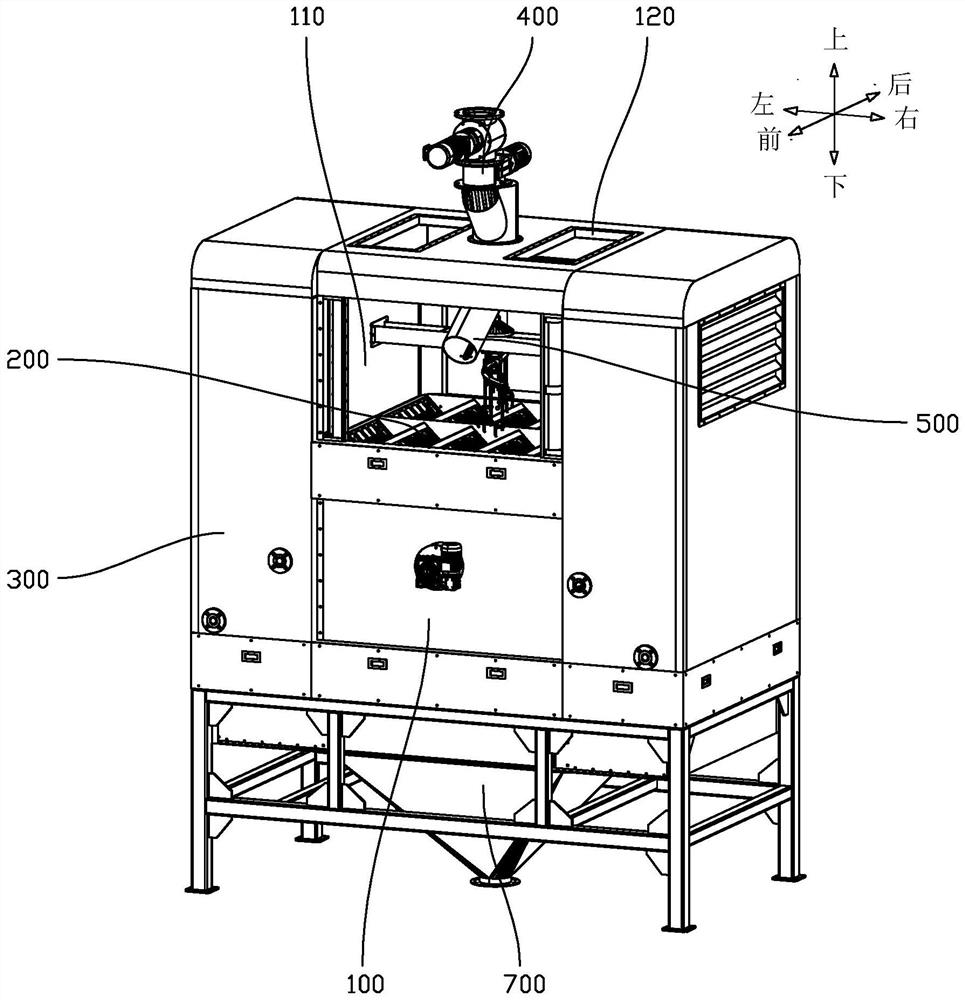

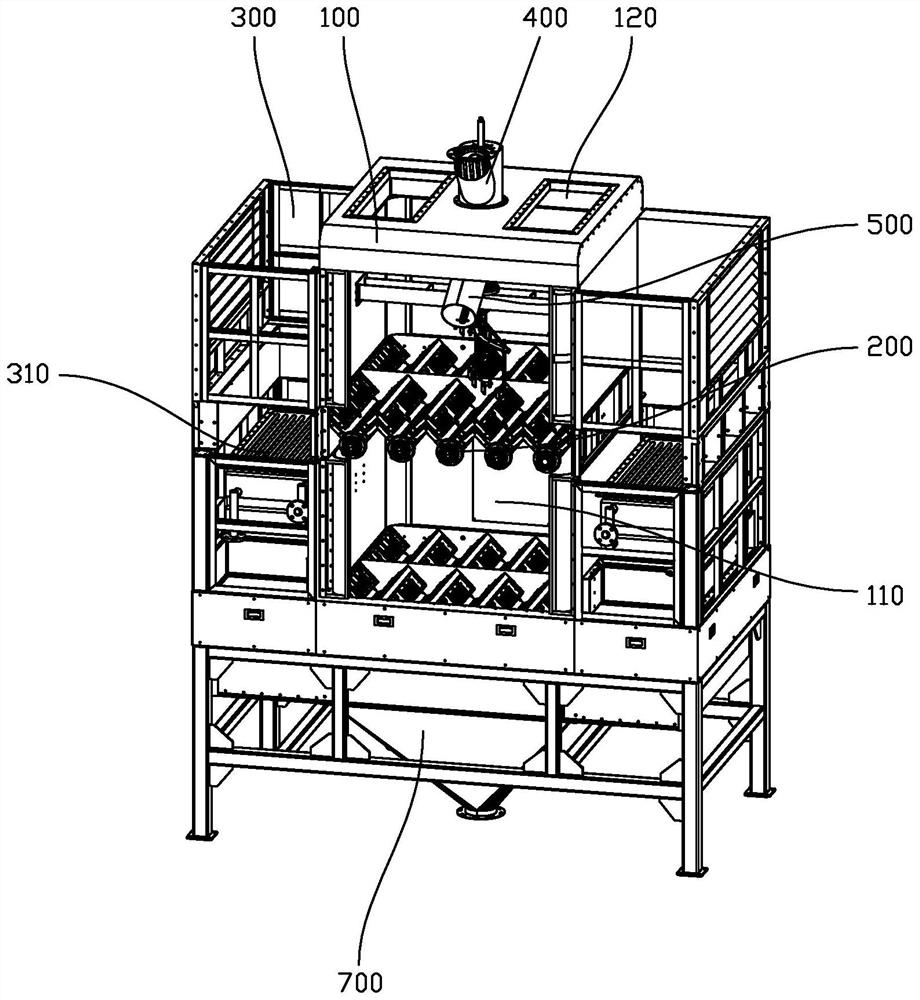

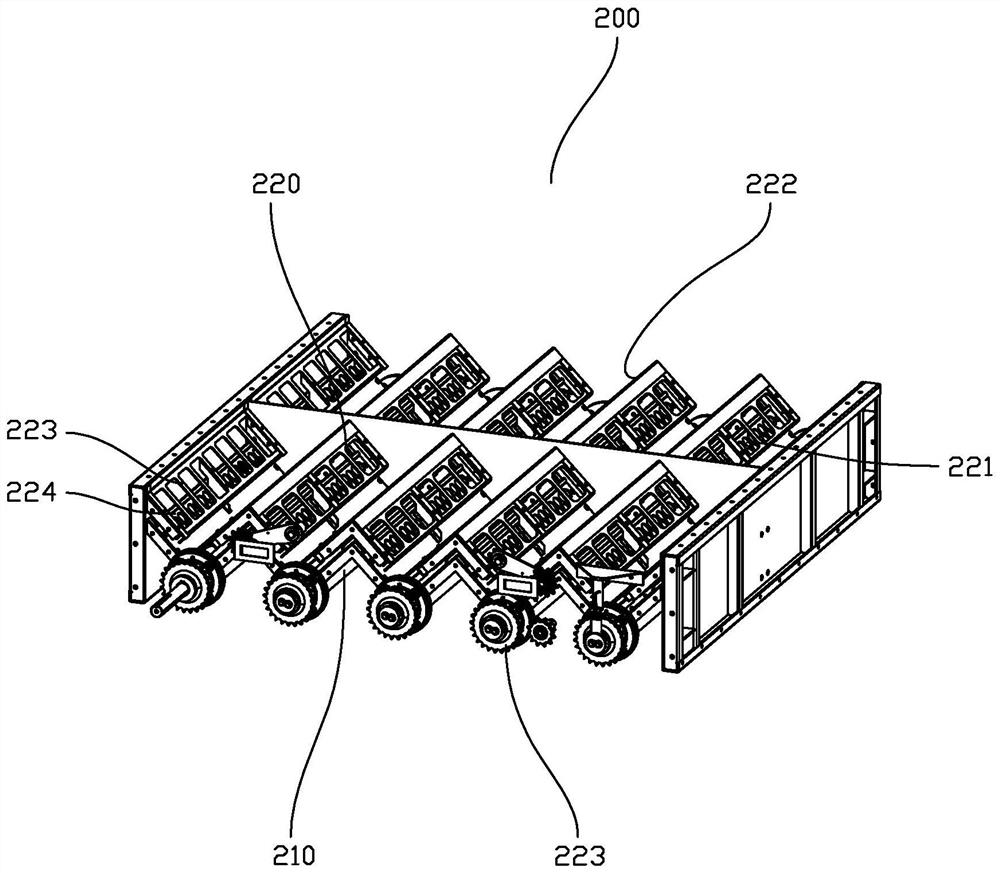

[0029] In order to make the purpose, technical solution and advantages of the present application clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. In the ensuing description some specific details are referred to for a thorough understanding of the present invention. While the present invention may be practiced without these specific details, the description and representations herein can be used by those skilled in the art to more effectively convey the substance of their work to others skilled in the art.

[0030] In addition, it should be noted that the terms "front side", "rear side", "left side", "right side", "upper side" and "lower side" used in the following description refer to directions in the drawings The words "inside" and "outside" respectively refer to directions toward or away from the geometric center of a specific component, and those skilled in the art who make simple and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com