Toner cartridge capable of preventing cleaning scraper from overturning

A technology for cleaning scrapers and toner cartridges, which is applied to electrical recording technology using charge graphics, equipment for electrical recording technology using charge graphics, and electrography, etc. It can solve work efficiency reduction, scraper flipping defects, printer jams, etc. problems, to achieve the effect of improving product quality and eliminating flipping defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

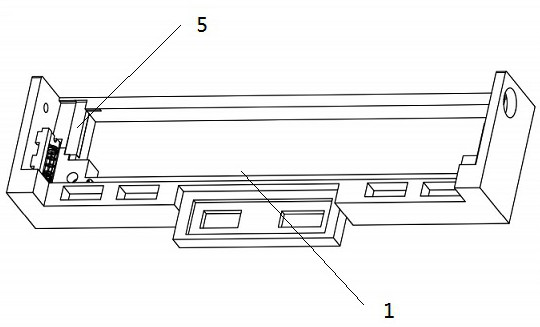

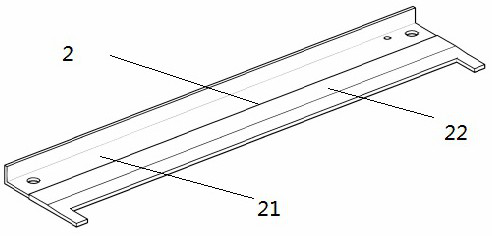

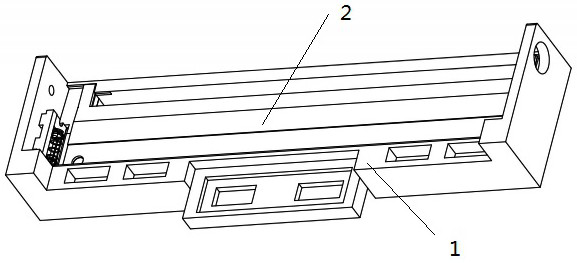

[0007] The present invention is described in detail below in conjunction with accompanying drawing: With reference to accompanying drawing, a kind of toner cartridge that prevents the cleaning blade from turning over includes a plastic shell 1, a photosensitive drum 4, a charging roller 3, a cleaning blade 2, a sealing sponge 5 and a sealing blade 6. The plastic shell 1 is a structural fixture of the toner cartridge; the photosensitive drum 4 is installed on the plastic shell, the charging roller 3 is installed on the plastic shell 1 in parallel with the photosensitive drum 4, and the surface of the charging roller 3 is in contact with the surface of the photosensitive drum 4 contact; the cleaning scraper 2 is composed of a metal bracket 21 and a polyurethane rubber strip 22, the rubber strip 22 is in a U-shaped structure, the bottom is fixedly connected with the metal bracket 21, and the cleaning scraper 2 is fixedly installed on the plastic shell 1 in parallel with the photose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com