Intelligent control system and device for pneumatic conveying of powder pipeline

An intelligent control system and pipeline gas technology, applied in conveyors, transportation and packaging, conveying bulk materials, etc., can solve the problems of inconvenient operation, inconvenient operation of operators, low degree of intelligence, etc., to achieve convenient disassembly and cleaning, improve Ease of maintenance, easy and quick disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

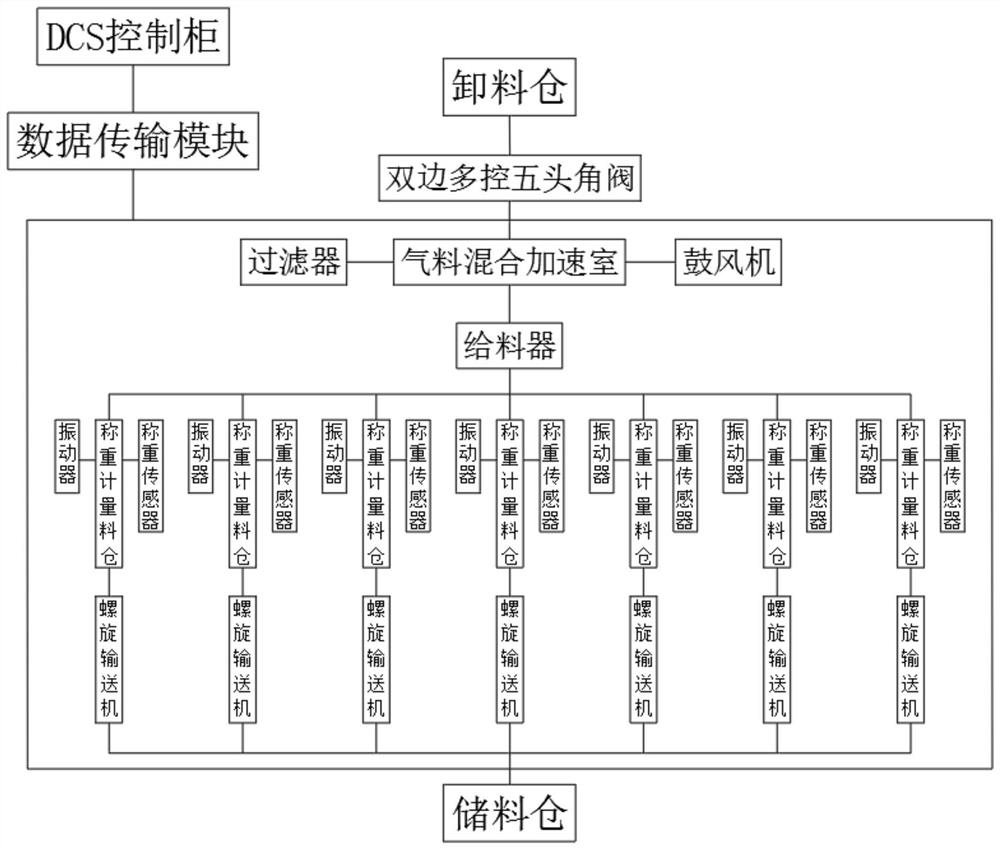

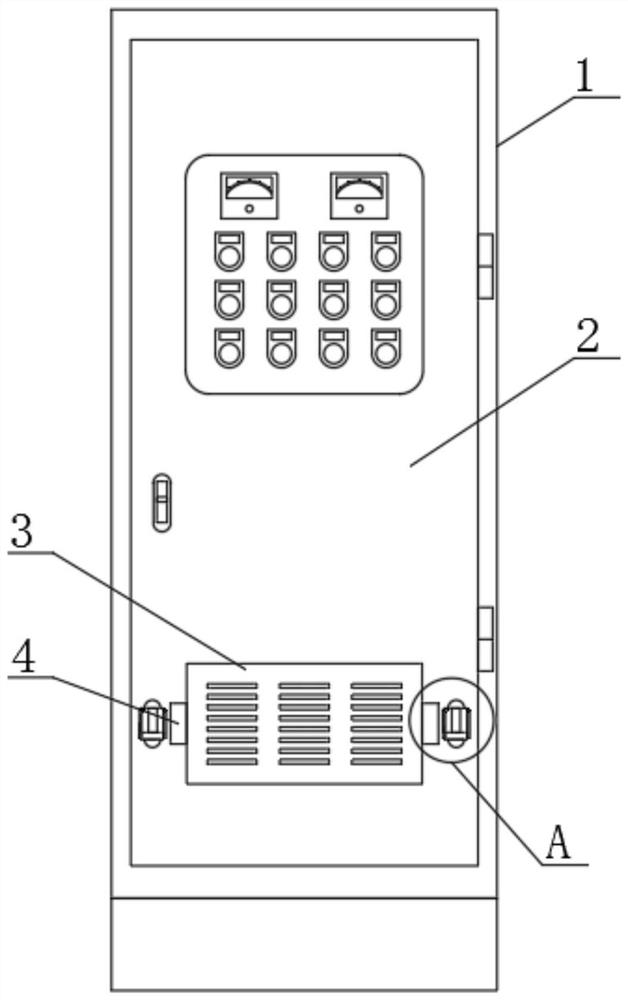

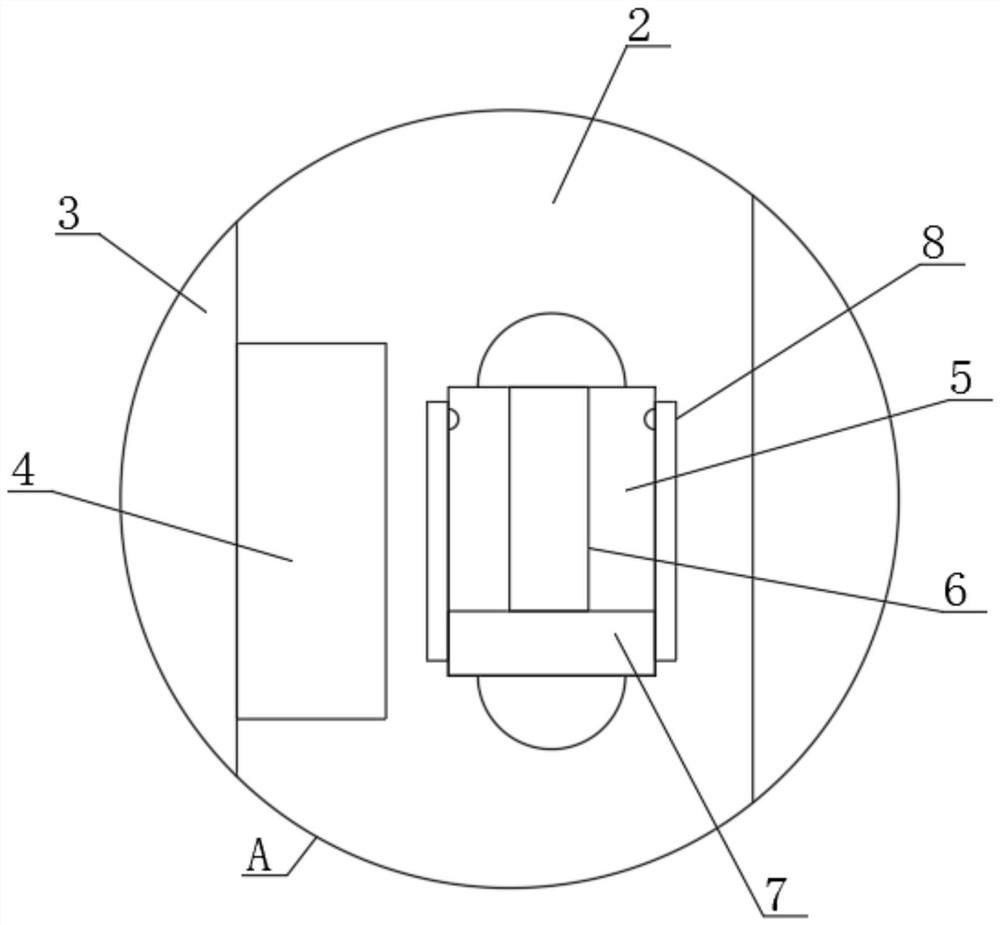

[0023] see Figure 1 to Figure 5 , the present invention provides a technical solution: an intelligent control system for powder pipeline air delivery, including a DCS control cabinet, a data transmission module, a storage bin, a plurality of screw conveyors, a plurality of weighing and measuring bins, and a feeder , gas-material mixing acceleration chamber, filter, blower, double-sided multi-control five-head angle valve and unloading bin. The storage bin is connected to multiple screw conveyors through the conveying pipeline, and each screw conveyor is connected to a weighing machine through the conveying pipeline. The weighing silo is used to convey the material to the weighing and measuring silo. Each weighing and measuring silo is equipped with a vibrator and a weighing sensor. The weighing sensor can sense the material in the weighing and measuring silo in real time. When the weight of the material reaches the set value, it will send a signal to the DCS control cabinet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com