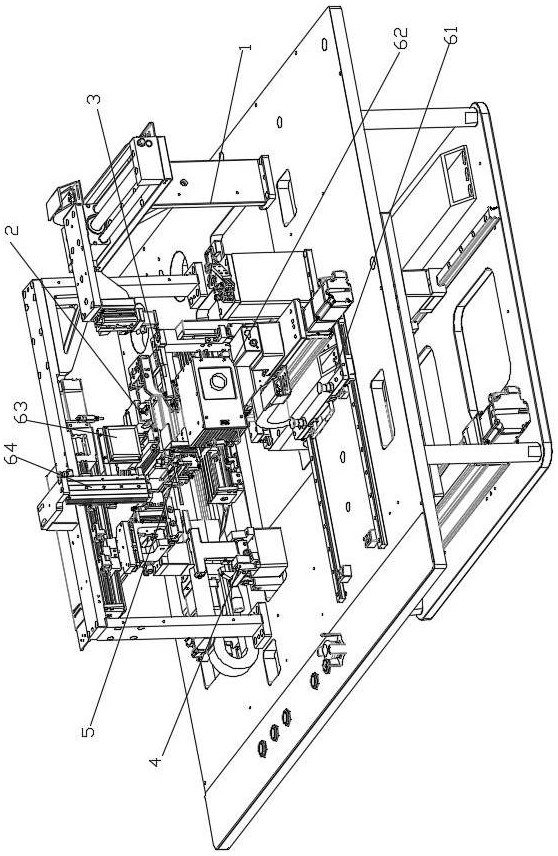

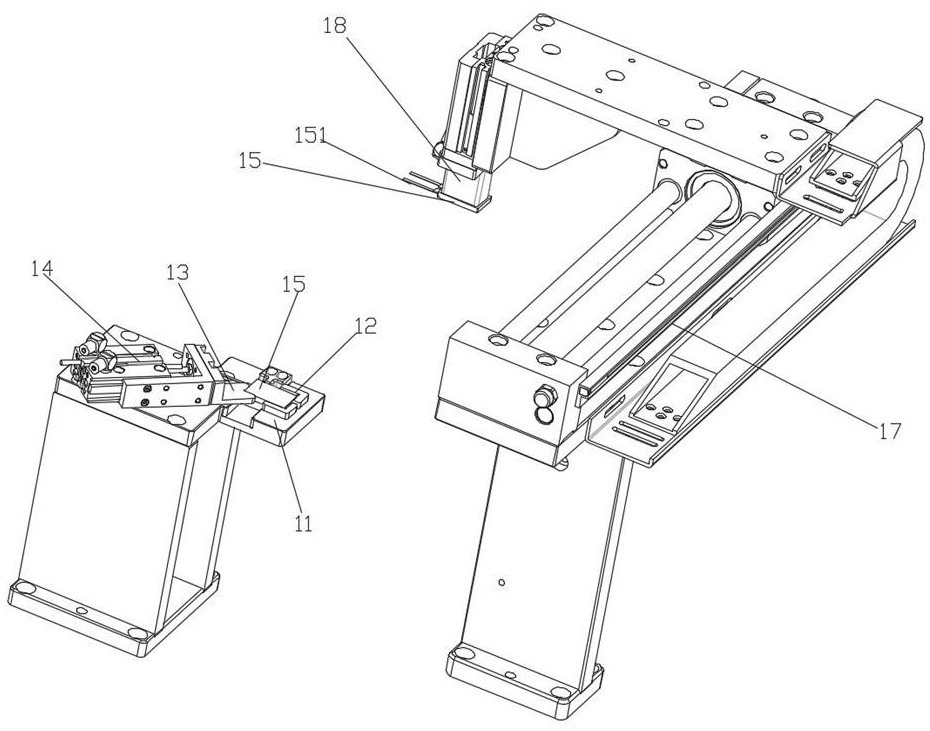

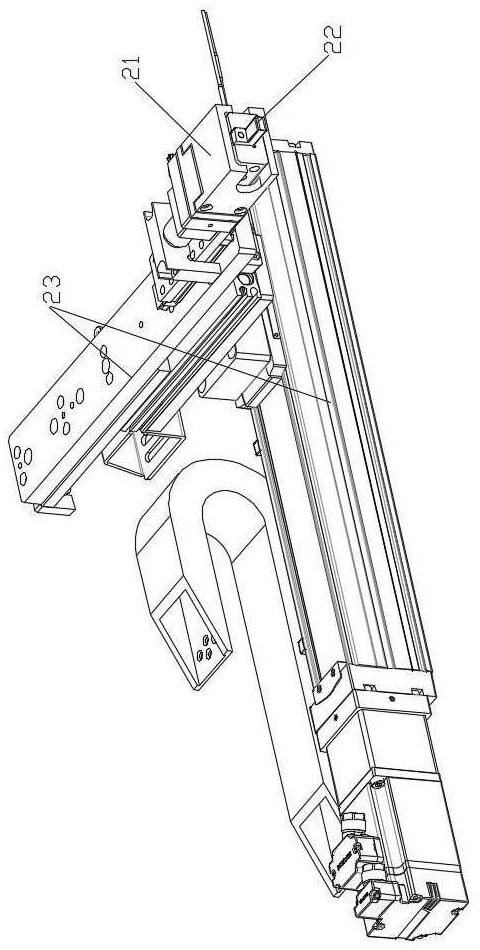

Battery film winding process and equipment

A battery and film winding technology, which is applied to battery pack components, circuits, electrical components, etc., can solve the problems of low processing efficiency, affecting the appearance of the battery cell, and affecting the electrochemical performance of the battery cell, so as to avoid wrinkles and improve the winding film Accuracy, the effect of ensuring the quality of the winding film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0035] refer to Figure 10 As shown, a battery winding process includes the following steps:

[0036] Obtain the center line in the length direction of the battery and the center line in the length direction of the protective film, and place the center line in the length direction of the battery and the center line in the length direction of the protective film in an overlapping manner;

[0037] Hot press one end of the protective film on the starting end of the first side of the battery, and leave a length of starting film, pull the protective film so that the protective film is attached to the lead side and the second side of the battery in sequence, heat the protective film pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com