Multi-numerical control machine tool combined machining center of intelligent terminal camera ring

A technology of CNC machine tools and intelligent terminals, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing production costs, affecting the processing efficiency of camera rings, affecting the sales effect of finished camera rings, etc. The effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

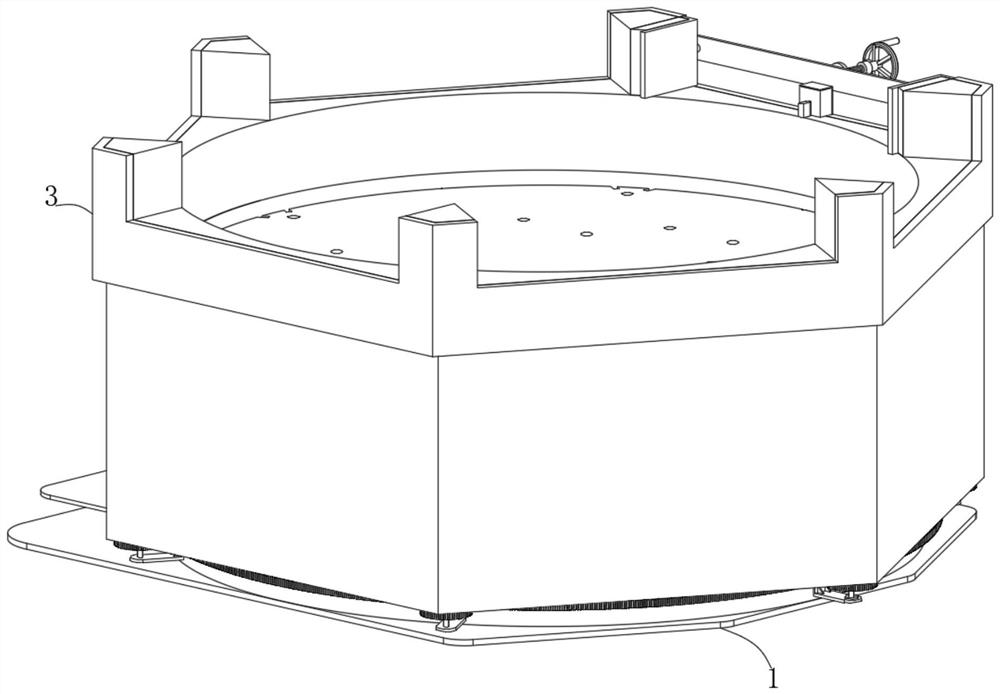

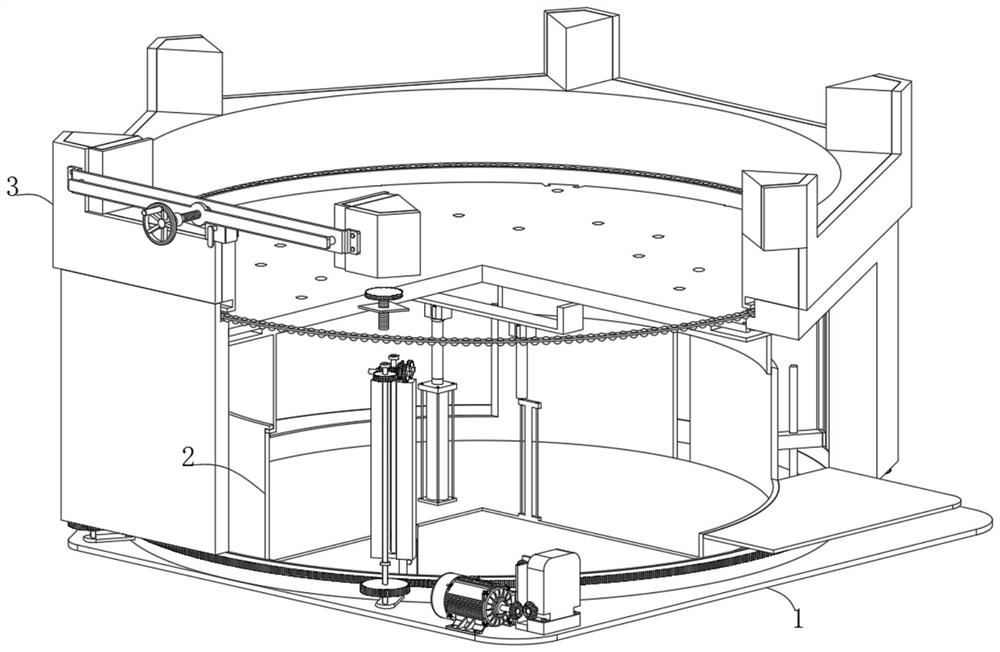

[0033] refer to Figure 1-Figure 10: A combined machining center of multiple CNC machine tools with an intelligent terminal camera ring, comprising: a limit mechanism 1, a support mechanism 2 and a positioning mechanism 3, the limit mechanism 1 includes a base 101, a driving part and a lifting part, and the base 101 is set up Provide the installation basis for setting other functional components of the equipment, and at the same time enable the equipment to be placed firmly in the designated use position. The outer surface of the base 101 is slidingly sleeved with a ring gear 110. The setting of the ring gear 110 cooperates with the first gear 109 so that the motor 103 can effectively drive the connecting gear. The moving shaft 111 rotates, and the bottom frame 102 is fixedly connected to the top of the base 101. The bottom frame 102 is set up to facilitate the installation and setting of other functional parts of the equipment. The top of the bottom frame 102 is equidistantly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com