A kind of bridge accessories processing equipment

A technology for processing equipment and accessories, applied in the field of bridge accessories processing equipment, can solve the problems of increasing the workload of operators, unfavorable to assembly line production, limiting production efficiency, etc., to reduce the participation of manual operations, speed up draining efficiency, and ensure products quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

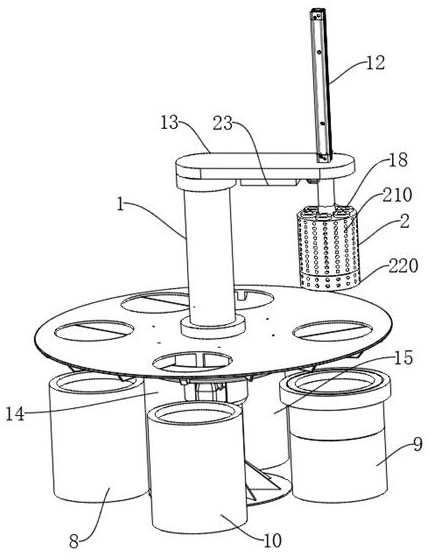

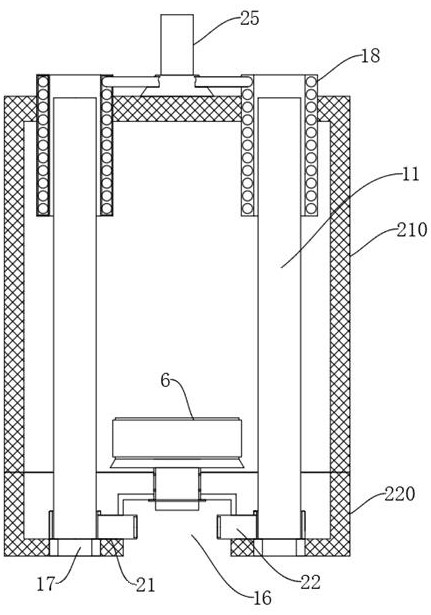

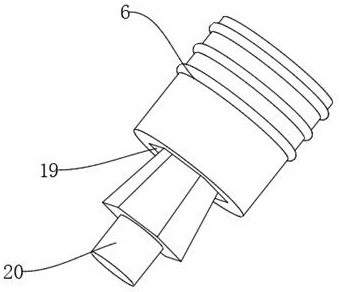

[0063] Such as Figure 1-Figure 8 As shown, a bridge accessories processing equipment includes a rotating frame 1 and a centralized processing cage 2 arranged relatively parallel to the rotating frame 1 through a connecting frame 13 and driven up and down by an electric telescopic rod 12. The screw parts 11 to be processed are inserted in the centralized processing There are 3 workpiece positions in the cage 2, and the rotating frame 1 is surrounded by an oil-removing soaking tank 10, a coating solution soaking tank 9, a draining tank 8, a heating and curing furnace 14, and a screw molding tank 15. The centralized processing cage 2 It is composed of a shield 210 and a base 220 that is clamped and fixed at the lower end of the shield 210, and the surfaces of the shield 210 and the base 220 are provided with a number of holes;

[0064] The middle part of the base 220 is provided with a circular recess 16, and the base 220 is provided with a plurality of workpiece positions 3 aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com