Chip stripping mechanism, stripping machine and stripping method

A peeling mechanism and peeling machine technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems of waste costs of chemicals, unsatisfactory production, strong chip damage, etc., to reduce chip damage rate, Reduction of tool replacement time and improvement of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

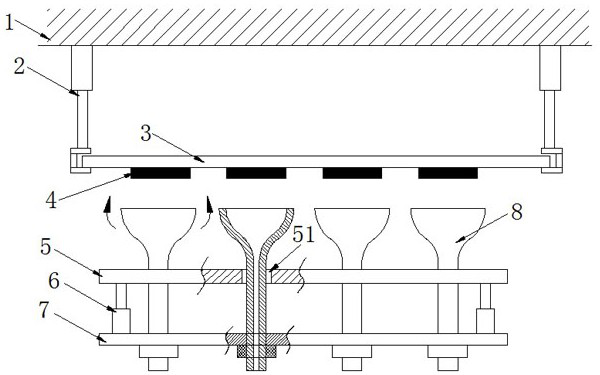

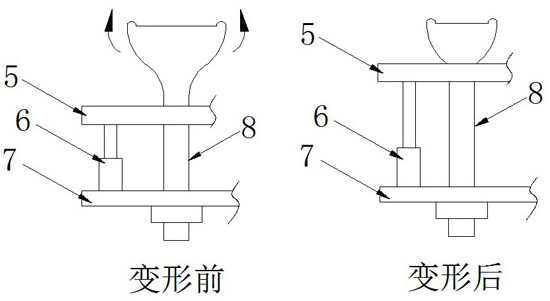

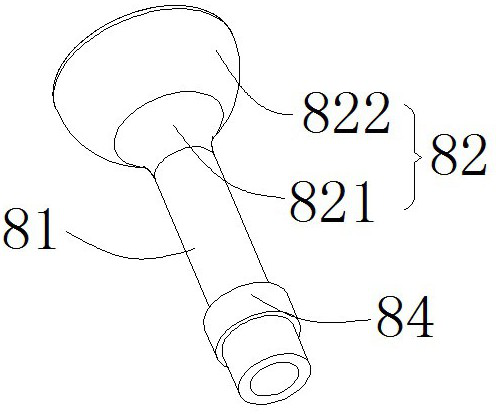

[0023] In order to better understand the purpose, structure and function of the present invention, below in conjunction with appendix Figure 1-5 , a chip stripping mechanism, stripping machine and stripping method proposed by the present invention will be further described in detail.

[0024] Conventional technology uses chemical and physical methods to separate the UV film from the chip 4 , but in actual production there are problems such as wasting the cost of dissolving chemicals and seriously damaging the chip 4 by peeling off. And a kind of chip stripping mechanism of the present invention, not only does not need degumming, can also reduce the damage rate of chip 4 when peeling off, and its structure comprises the telescopic manipulator 2 that will be installed with the carrier film 3 of chip 4 clamping position, can The telescopic manipulator 2 can be clamped and positioned by using a conventional industrial programming robot arm, mainly because it also includes the ads...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com