Combustion device and gas stove

A technology for a combustion device and a gas stove, which is applied to heating fuels, household stoves/stoves, gaseous heating fuels, etc., and can solve problems such as the influence of the service life of gas stoves and the easy damage of ignition needles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

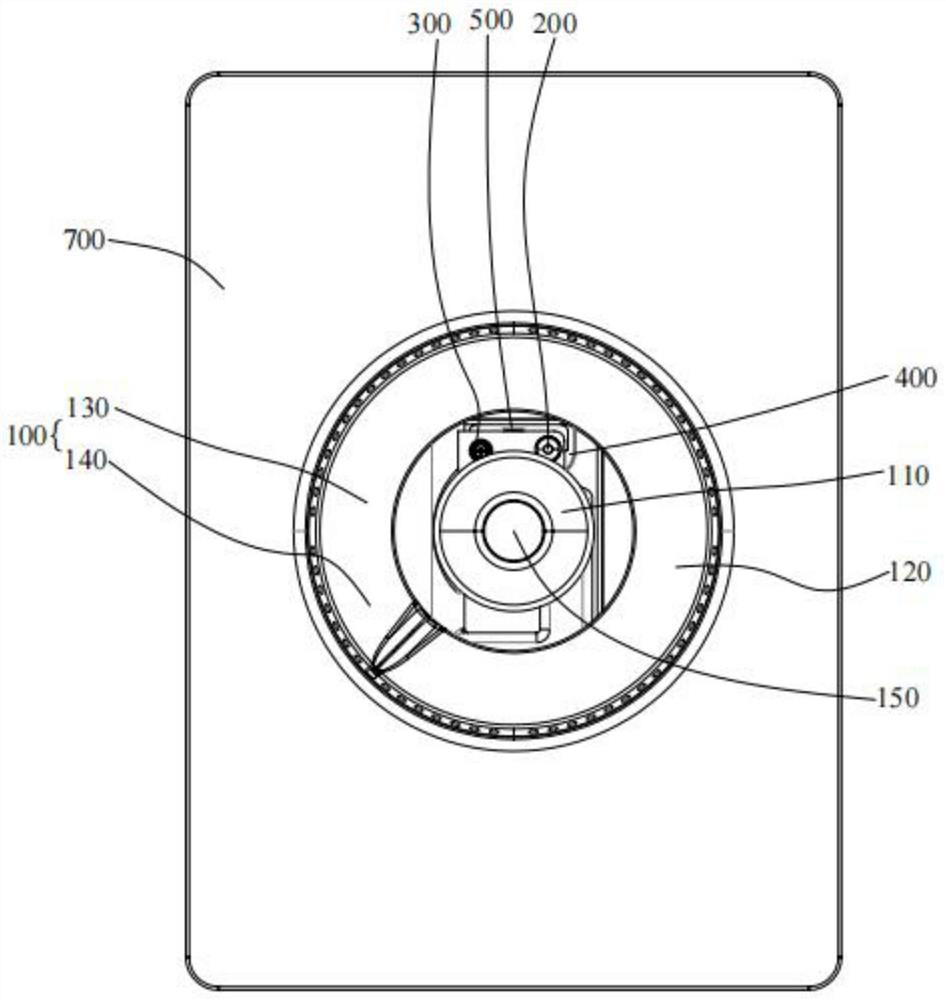

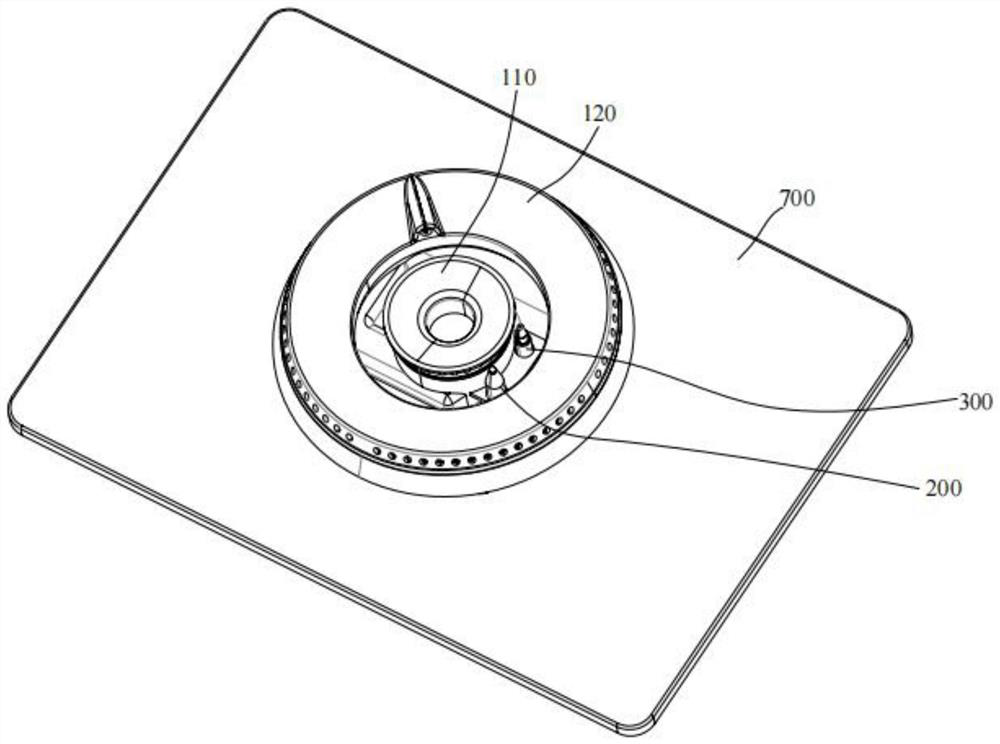

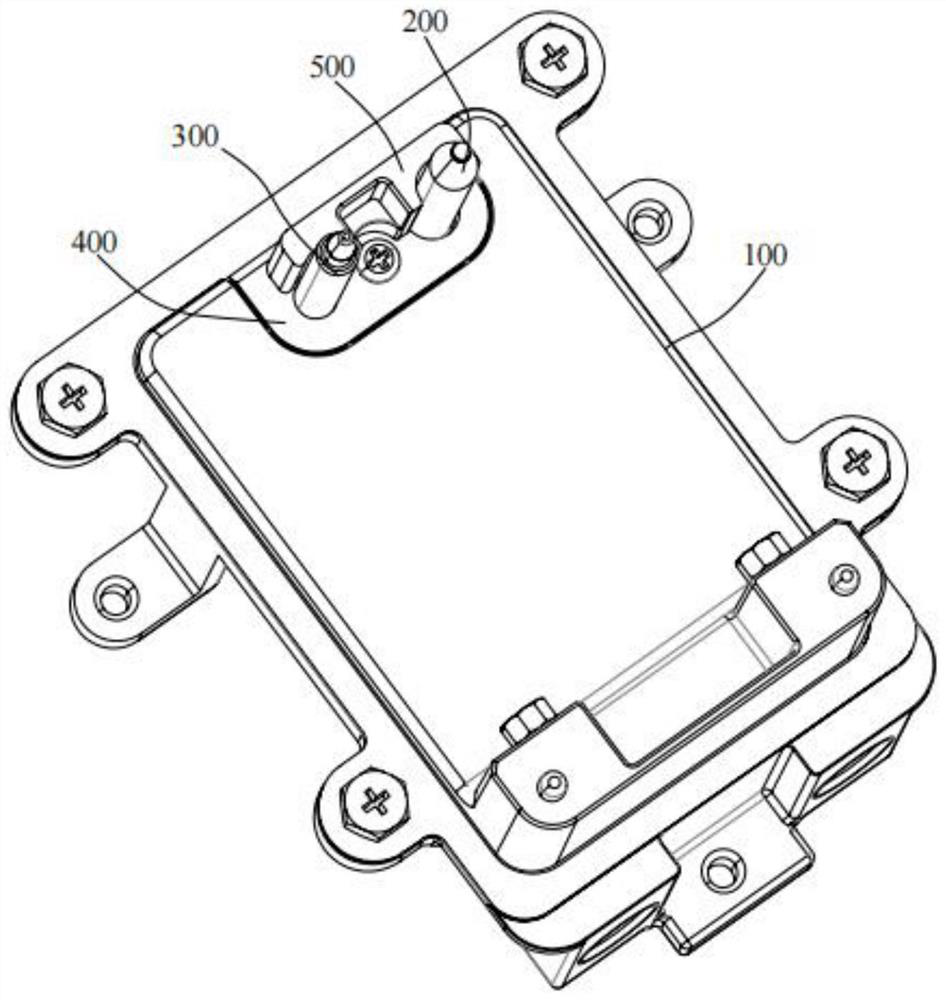

[0058] Please refer to Figure 1 to Figure 9 , the embodiment of the present application discloses a combustion device, including a furnace body 100, an ignition needle 200, a thermocouple 300, a baffle plate 500 and at least one side plate. The combustion device can be a gas cooker or other combustion equipment using gas as a raw material.

[0059] Wherein, the furnace body 100 is the basic component of the combustion device of the present application, and the furnace body 100 can provide an installation basis for at least some other components of the combustion device. Because the gas burner can generate high-temperature flames, the furnace body 100 can be made of high-temperature-resistant metal materials, specifically cast iron materials. The furnace body 100 can communicate with the gas pipeline, and the gas can be input into the furnace body 100 through the gas pipeline, and the external air can also enter the furnace body 100, and mix with the gas entering the furnace ...

Embodiment 2

[0099] Based on the above combustion device, an embodiment of the present application further proposes a gas stove, which includes the above combustion device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com