Adsorption type intelligent hoisting system for warehouse logistics

A storage logistics and adsorption technology, which is applied in the field of intelligent hoisting systems for adsorption storage and logistics, can solve the problems of single hoisting gripper, single grip, poor stability, etc., and achieves accurate grasping of objects, increased stability, The effect of good mechanism dynamic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

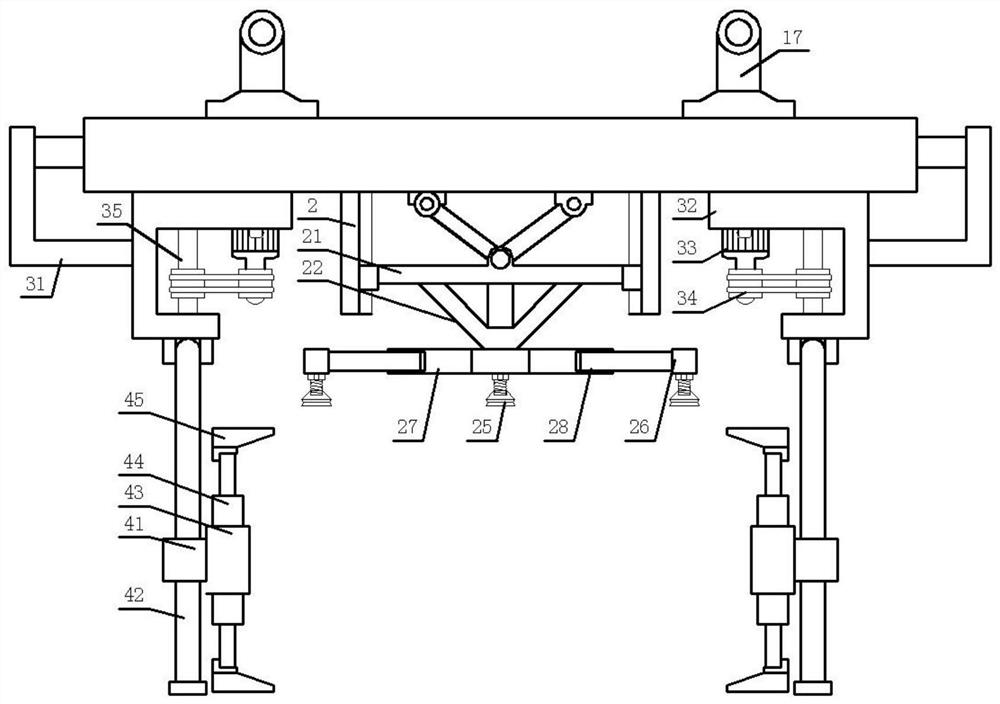

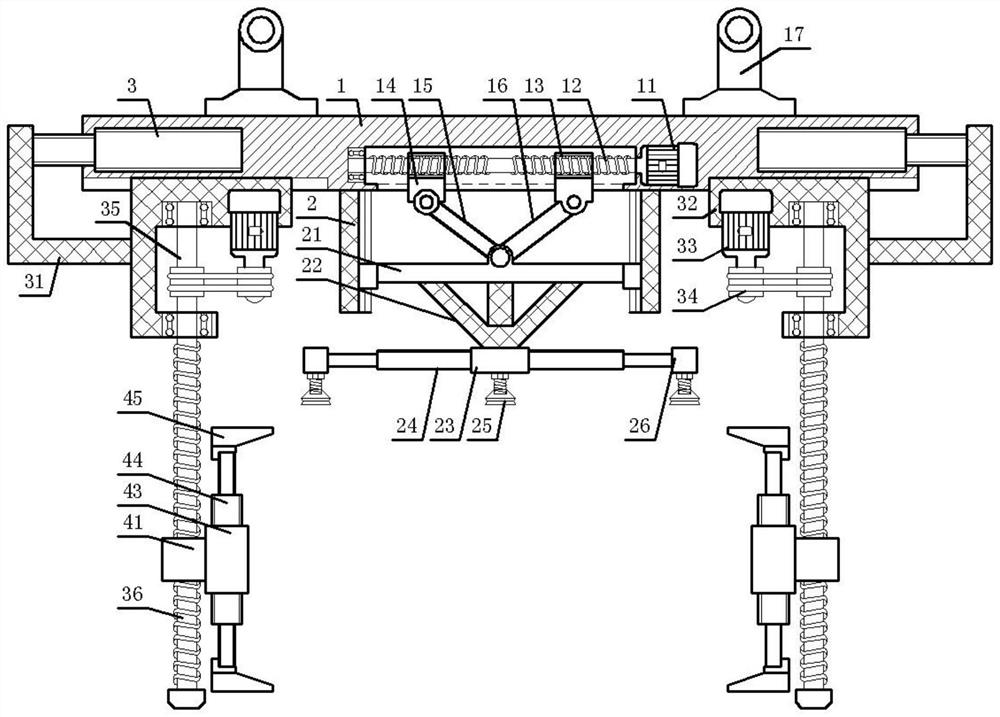

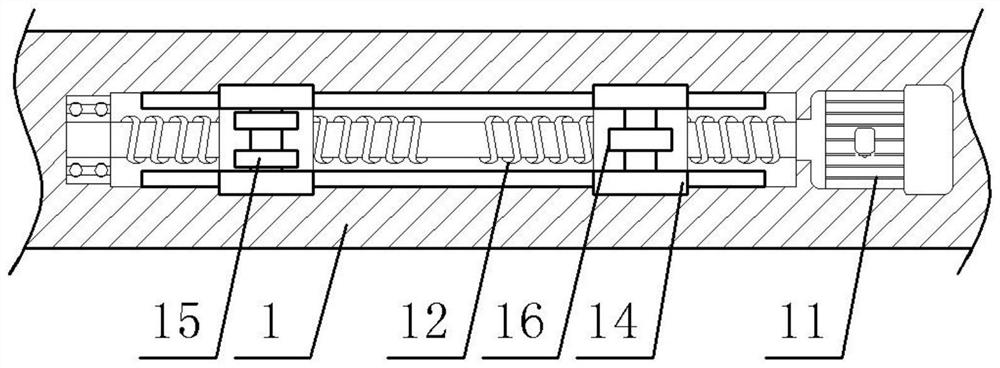

[0030] Embodiment 1: In order to solve the problem that the current hoisting gripper is relatively single and has poor stability, this embodiment provides an intelligent hoisting system for adsorption storage and logistics. See Figure 1-7 Specifically, it includes a bottom plate 1, a screw mechanism, a sucker mechanism, a driving mechanism, and a clamping mechanism. The bottom plate 1 is a rectangular plate placed horizontally and horizontally, and the middle part of the bottom plate 1 is horizontally recessed. A screw mechanism is installed inside, and a pair of vertically fixed side plates 2 are arranged on the bottom surface of the bottom plate 1 on both sides of the rectangular groove, and a horizontally placed lifting plate 21 is arranged between the pair of side plates 2, and the lifting plate 21 A suction cup mechanism is installed on the bottom surface of the base plate 1; a pair of U-shaped plates 32 slidingly connected are provided on both sides of the bottom surface...

Embodiment 2

[0035] Embodiment 2: In Embodiment 1, there is still the problem that the clamping direction cannot be changed according to the width distance of the side of the goods. Therefore, on the basis of Embodiment 1, this embodiment also includes:

[0036] In the present invention, the driving mechanism includes a linkage shaft 35, a lead screw 36, a driving motor 33, and a driving belt 34. Positioning bearings are recessed at the upper and lower ends of the U-shaped plate 32, and between the two positioning bearings A vertically placed linkage shaft 35 is provided, and the two ends of the linkage shaft 35 are respectively penetrated and inserted in the corresponding positioning bearings. Connected lead screw 36 is coaxially connected, and the bottom end of the lead screw 36 is provided with a lead screw stopper; the inner side of the top surface of the U-shaped plate 32 is recessed with a motor groove, and a drive motor 33 is installed in the motor groove , the model of the drive mo...

Embodiment 3

[0038] Embodiment 3: In this embodiment, the present invention also proposes a grabbing method for an intelligent hoisting system for adsorption storage logistics, including the following steps:

[0039] Step 1, the hoisting ring is connected to the crane through the steel wire rope of the crane, and the screw motor 11, the miniature telescopic cylinder 24, the electric push cylinder, the drive motor 33, and the double-axis telescopic cylinder 44 are respectively electrically connected to the external power supply through the power line, and the The suction cup 25 communicates with the external control air source through the air pipe, and drives the bottom plate 1 to move to the top of the goods to be transported through the crane control crane wire rope;

[0040] Step 2, according to the size of the top surface area of the goods, the expansion and contraction of the telescopic rod of the miniature telescopic cylinder 24 is controlled. With the cooperation of the hinge action...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com