Quick-opening type manual feeding device for material bin

A technology of feeding device and material silo, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of mixing impurities into silo and dust pollution at the feeding port, so as to suppress dust, reduce the probability of dust pollution, and reduce The effect of the probability of the problem of poor feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

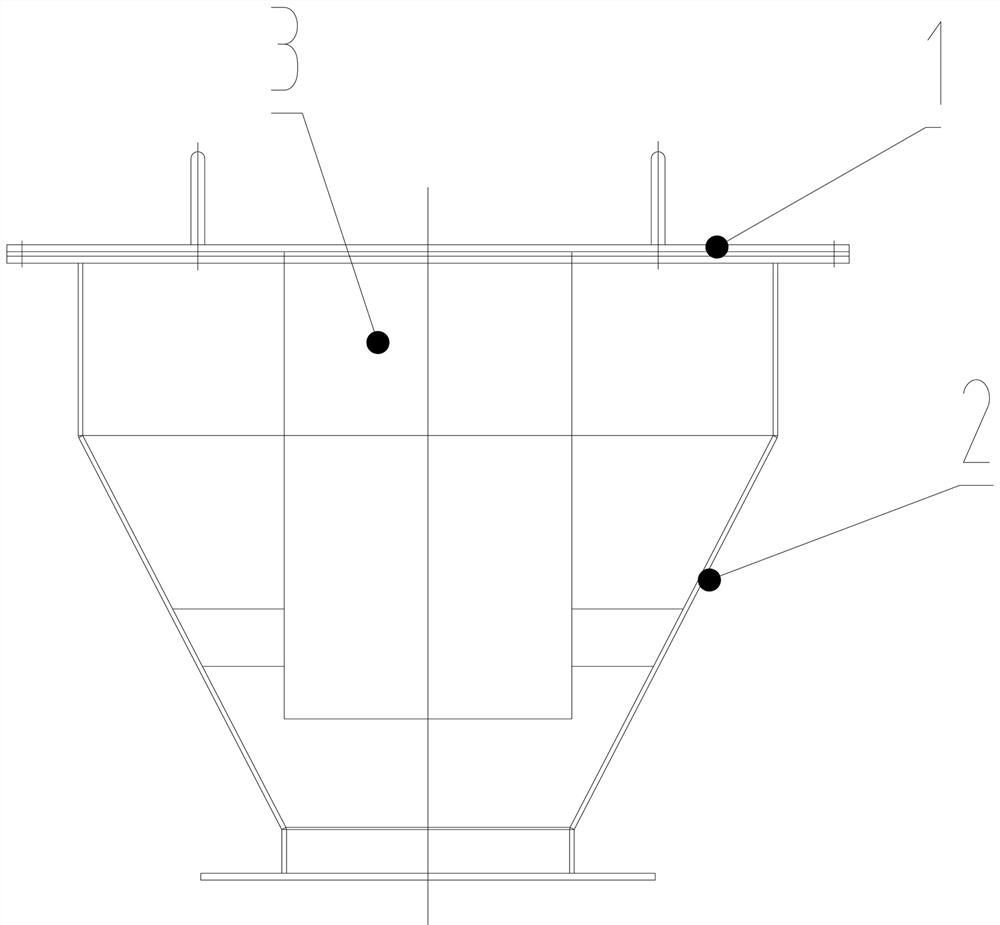

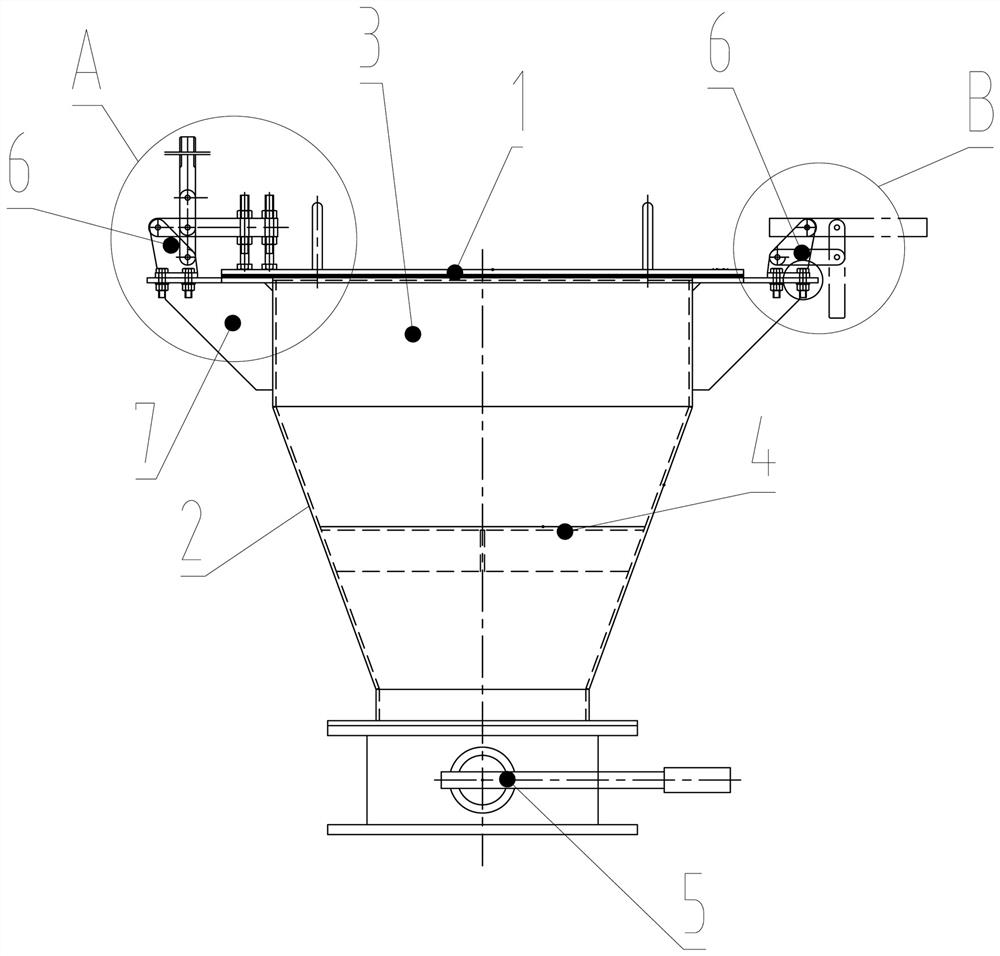

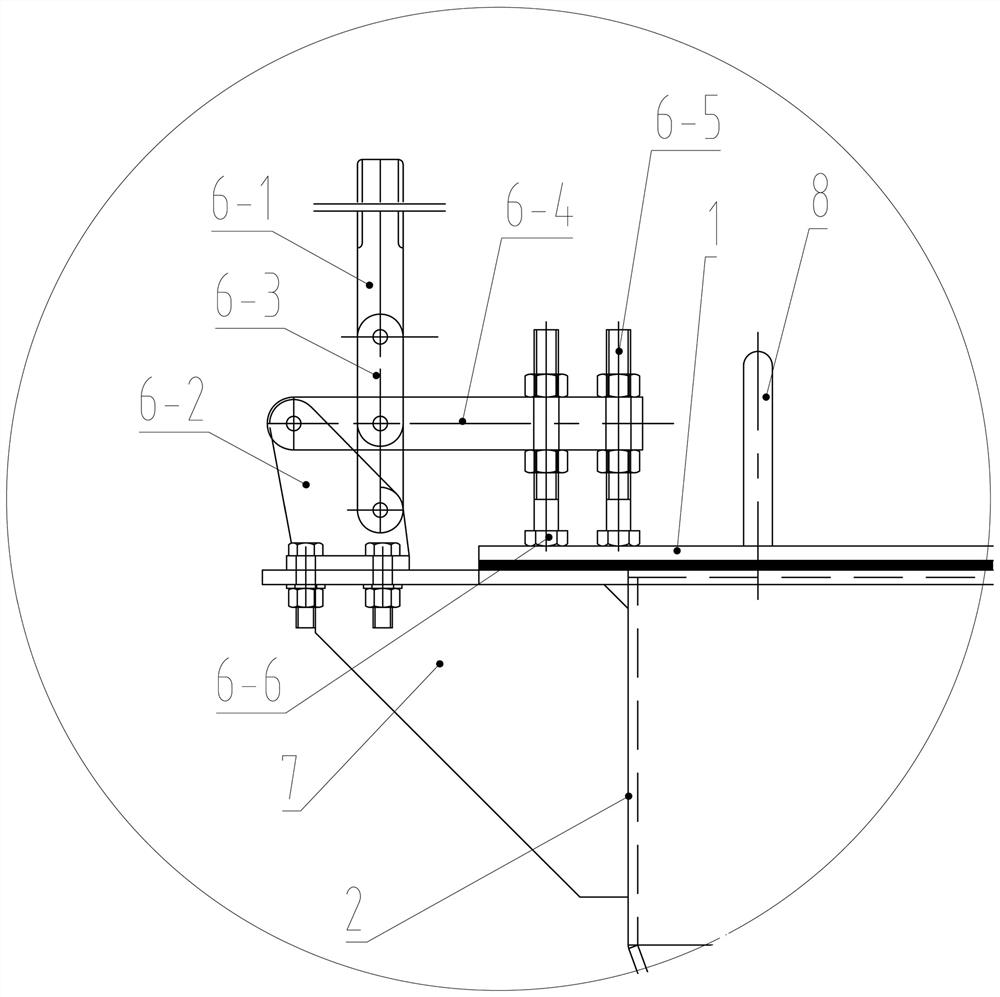

[0017] Such as figure 2 , image 3 As shown, a quick-opening manual feeding device for a material bin of the present invention includes: a feed port support 2 installed at the feed port 3, and a door cover 1 is installed at the entrance of the feed port support 2, and it also includes: a quick-open clip head, filter screen 4, butterfly valve 5; the quick-opening chuck is set on the top of the feed port support 2, and realizes quick opening and clamping functions on the door cover 1; the filter screen 4 is installed inside the feed port support 2; the butterfly valve 5 is installed on the The inner outlet of the feeding port support 2; the quick-open chuck of the door cover 1 includes three vertical quick clamps 6; on the top outer side wall of the feeding port support 2, mounting seats 7 are respectively fixed on the opposite positions; Three vertical fast clamps 6 are respectively installed on three mounts 7 . Among them, the vertical quick clamp can be realized by using a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com