Seeding quantity adjustment and seeding grain distance adjustment dual-adjustment combined seed-metering device

A technology for seeding rate and seed metering device, which is applied to the parts of the seeder, can solve the problem that the seed metering device cannot adapt to and meet the requirements of operation adjustment, and achieve the effects of simple and convenient adjustment operation, novel structure and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

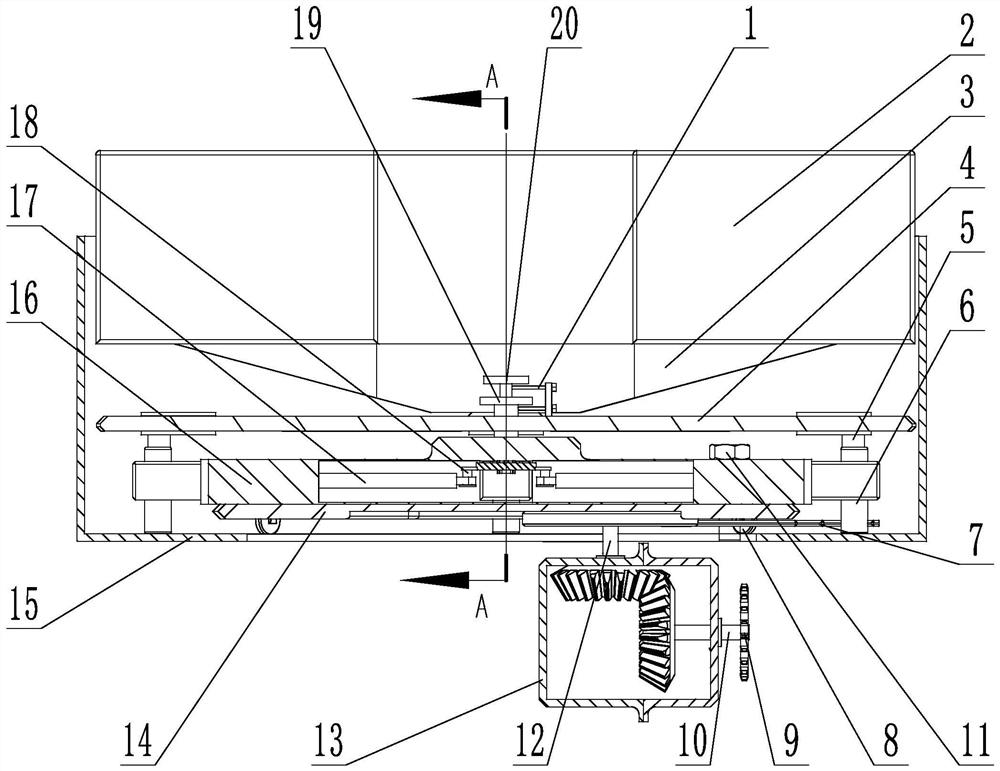

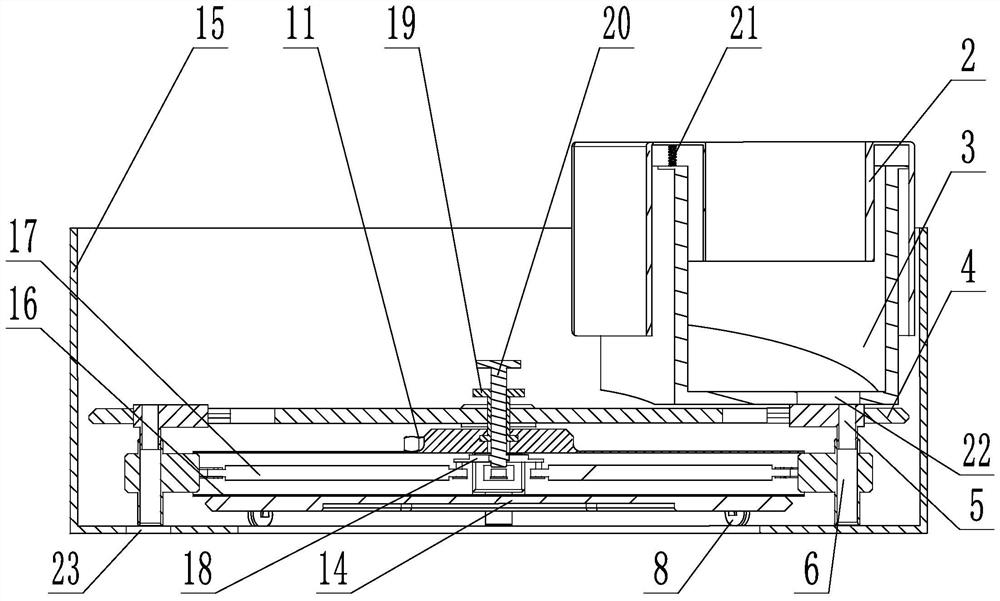

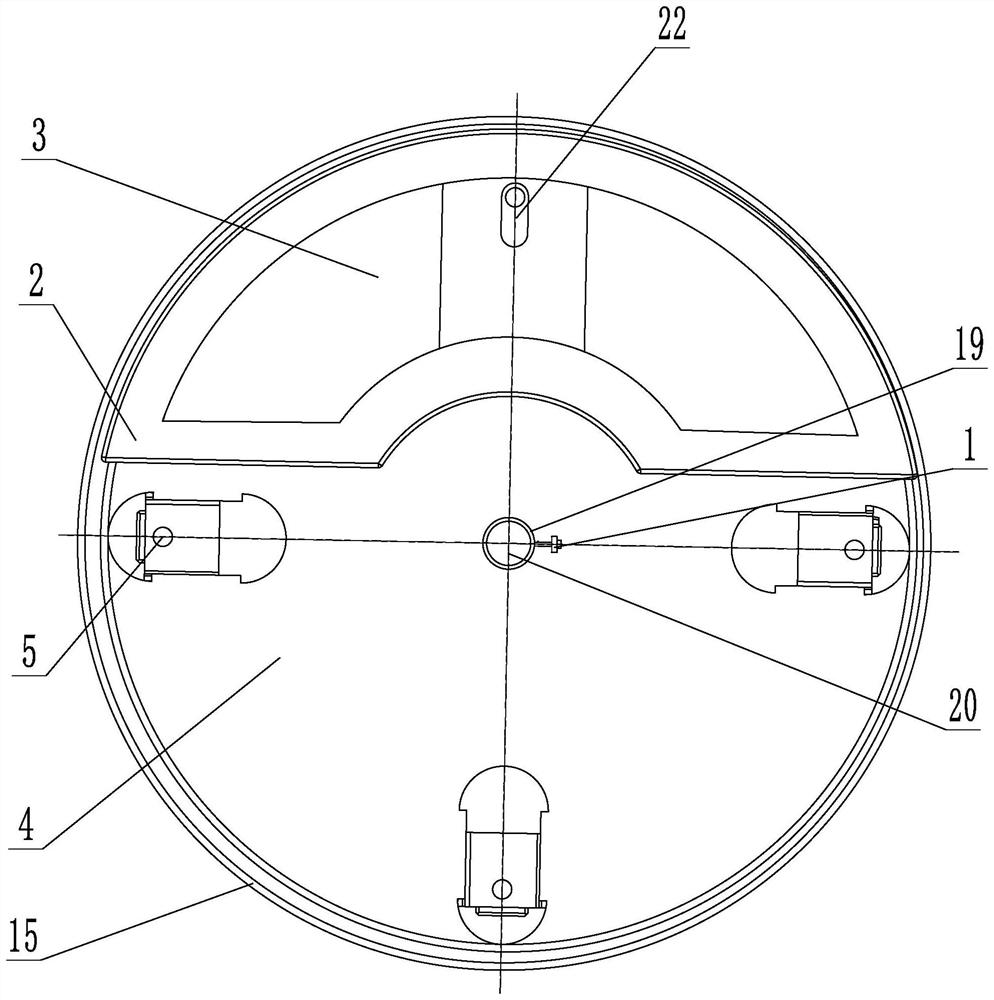

[0014] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A double-adjustable seed metering device for adjusting the amount of seeding and adjusting the seeding grain distance. On the inner bottom wall of the ring frame 15, a support plate 16 is coaxially and rotatably installed through the roller 8, and the support plate 16 is passed on the bottom wall surface. Bolt 11 coaxial fixed track disk 14, on the wall surface of the inner hole of track disk 14, four arc-shaped grooves 25 are evenly distributed along the circumferential direction, and on the support plate 16, they are evenly distributed along the circumferential direction and can be Four lower seed tubes 6 are assembled in a radially movable manner, the lower end surfaces of the four lower seed tubes 6 are in contact with the inner bottom wall surface of the ring frame 15, and the coaxial arrangement at the upper part of the support plate 16 The upper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com