Ka-band wide-stop-band filtering power divider

A technology of wide stop band and power divider, applied in the field of communication, to achieve the effect of excellent out-of-band suppression characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

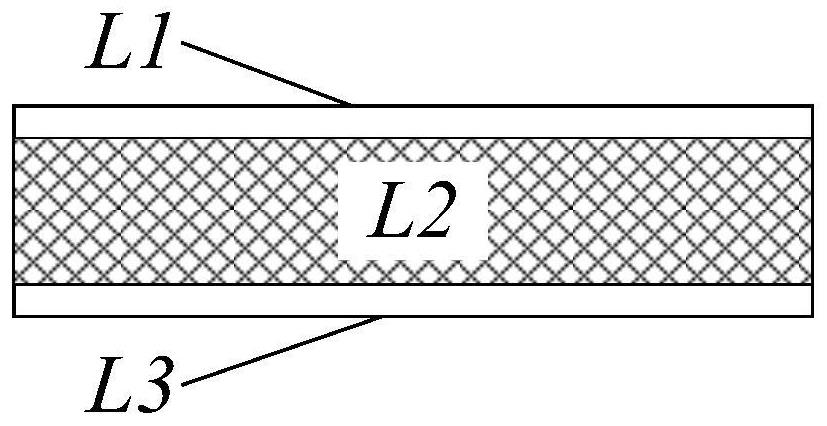

[0052] See figure 1 , figure 1 A schematic structural diagram of a Ka-band wide stopband filter power divider provided by an embodiment of the present invention. The filter power divider includes a first metal layer L1, a dielectric layer L2 and a second metal layer L3 stacked in sequence. Specifically, the first metal layer L1 , the dielectric layer L2 and the second metal layer L3 are arranged sequentially from top to bottom.

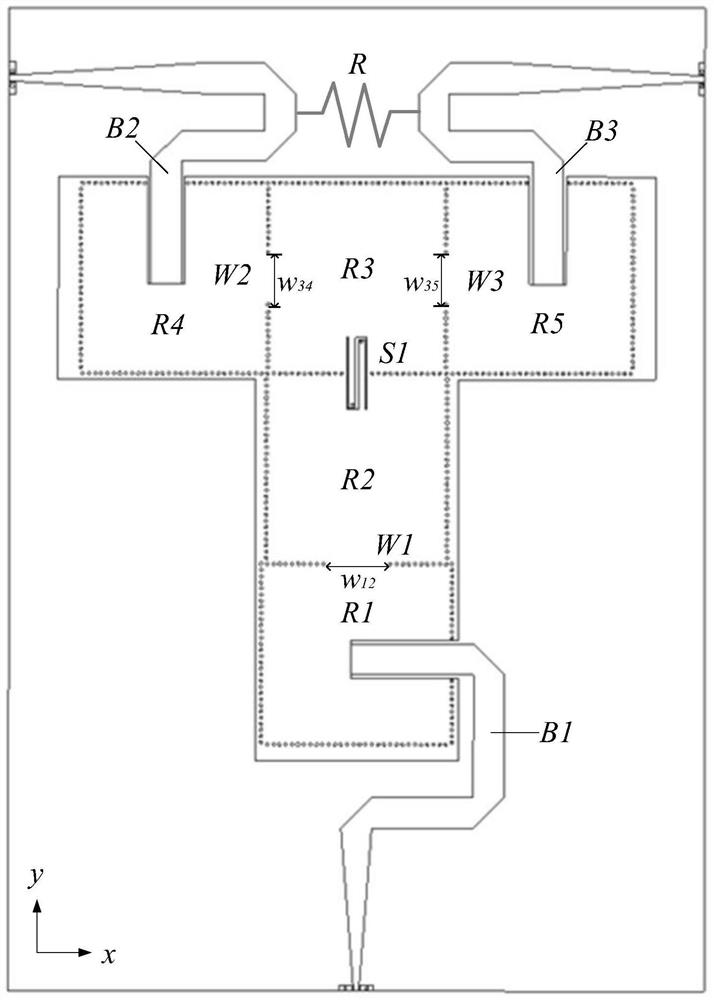

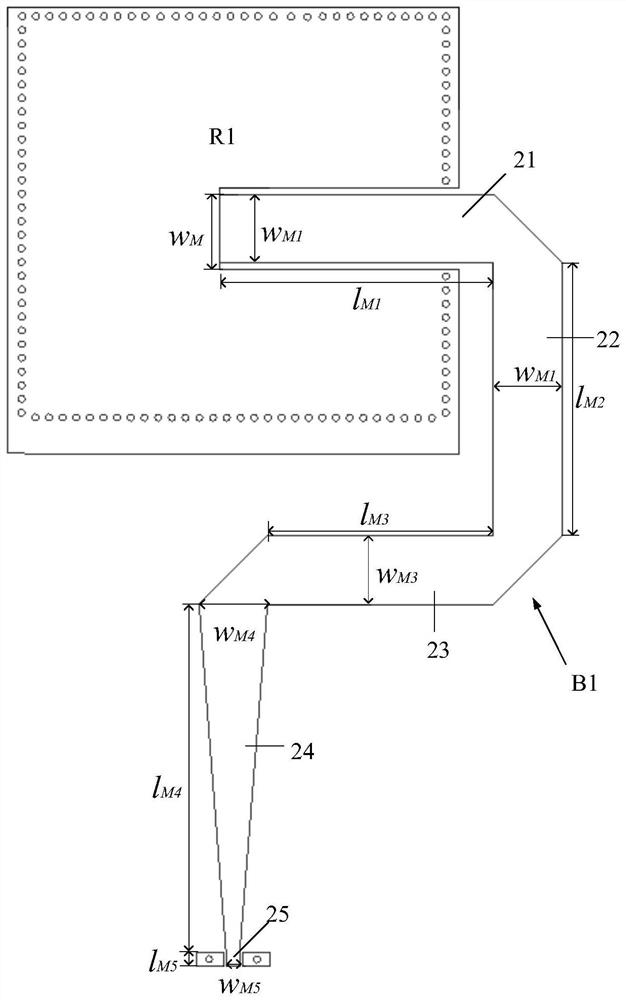

[0053] See figure 2 , figure 2 A top view of the first metal layer and dielectric layer of a filter power splitter provided by an embodiment of the present invention.

[0054] An input coupling line B1 , a first output coupling line B2 and a second output coupling line B3 are disposed on the sidewall of the first metal layer L1 , and an S-shaped groove S1 is opened in the middle of the first metal layer L1 . The dielectric layer L2 runs through a plurality of conductor columns, and the plurality of conductor columns form a first resonant cavity...

Embodiment 2

[0086] See Figure 10 , Figure 10 A schematic structural diagram of another Ka-band wide stop-band filter power divider provided by an embodiment of the present invention. The filter power divider includes a first metal layer L1, a dielectric layer L2 and a second metal layer L3 stacked in sequence. Specifically, the first metal layer L1 , the dielectric layer L2 and the second metal layer L3 are arranged sequentially from top to bottom.

[0087] See Figure 11 , Figure 11 A top view of the first metal layer and the dielectric layer of another filter power splitter provided by an embodiment of the present invention.

[0088] An input coupling line B1 , a first output coupling line B2 and a second output coupling line B3 are disposed on the sidewall of the first metal layer L1 , and an S-shaped groove S1 is opened in the middle of the first metal layer L1 . The dielectric layer L2 runs through a plurality of conductor columns, and the plurality of conductor columns form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com