LED backlight matrix driving circuit and driving voltage detecting and adjusting method thereof

A driving circuit and driving voltage technology, applied in the field of communication, can solve the problems of increasing chip cost, poor flexibility, increasing chip wiring area, etc., and achieve the effect of fast and accurate adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

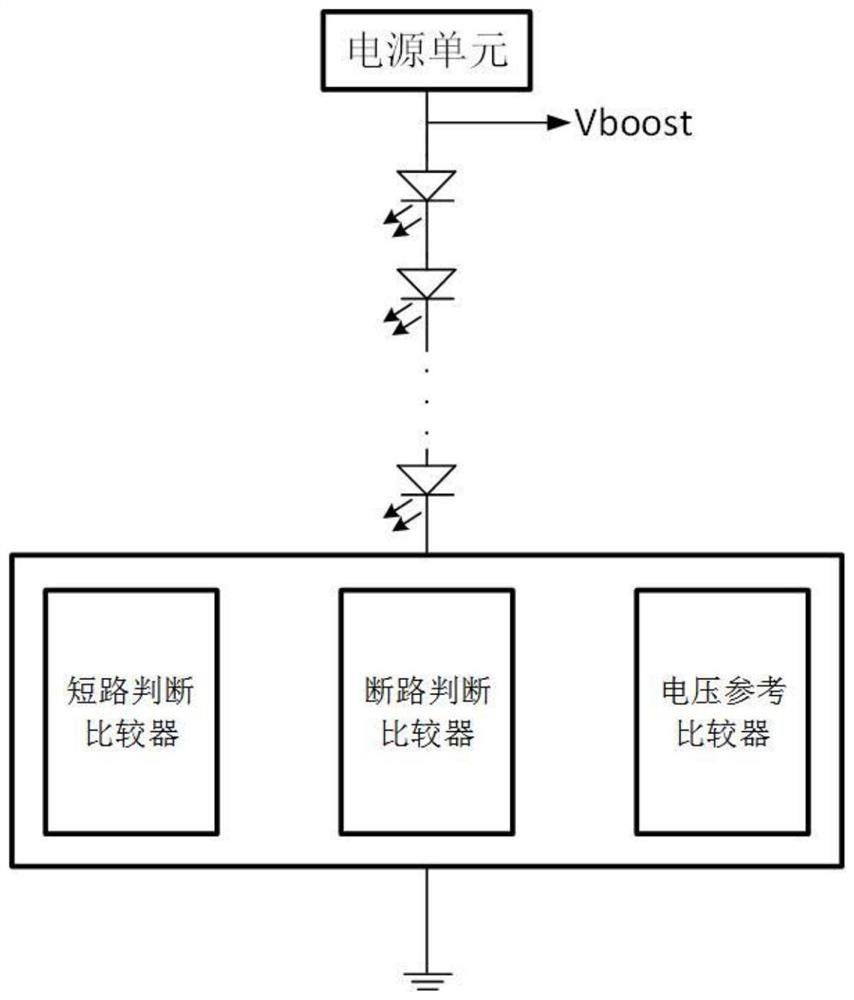

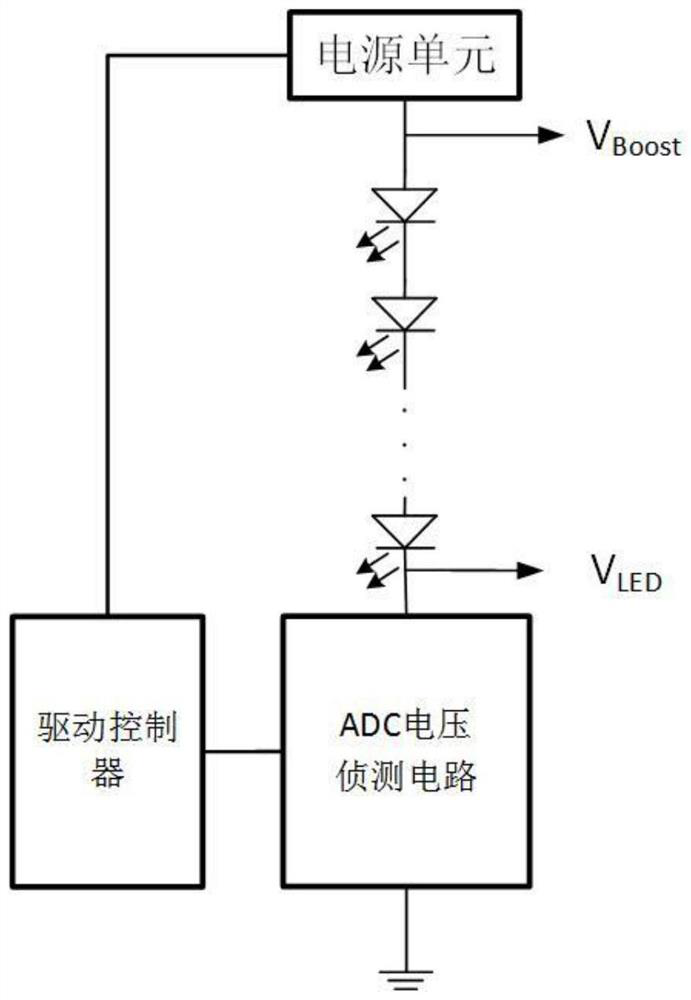

[0024] In order to make the purpose, technical solution and advantages of the present invention clearer, the following in conjunction with the attached Figure 3-5 The present invention will be described in further detail.

[0025] according to image 3 As shown, the LED backlight matrix drive circuit with voltage regulation unit of the present invention includes a power supply unit, LED light strings, ADC voltage detection circuit and a drive controller.

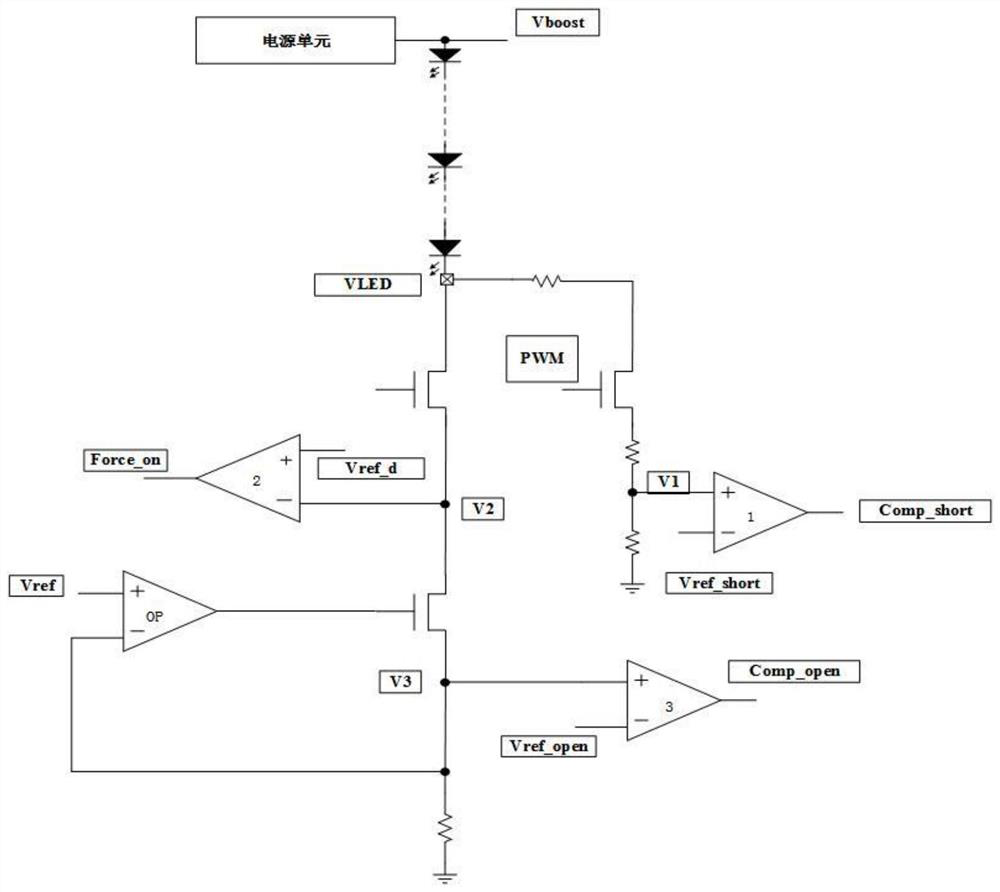

[0026] In this embodiment, the ADC voltage detection circuit is used to detect the voltage value V of the negative terminal of the LED light string led For detection, the negative terminal voltage value V will be obtained led Accurate measurement value, the ADC sampling module in the ADC voltage detection circuit can measure the voltage value V of the negative terminal of the LED light string led It is converted into a voltage numerical code and output to the drive controller.

[0027] In this embodiment, for the negati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com