Steel structure protective shed tunnel for crossing section of high-voltage power line and railway

A high-voltage power, cross-over technology, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems affecting the daily operation of high-speed railways, affecting the safe operation of railways, and the support structure is easily damaged, so as to achieve easy installation and replacement, Effects of enhancing safety and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

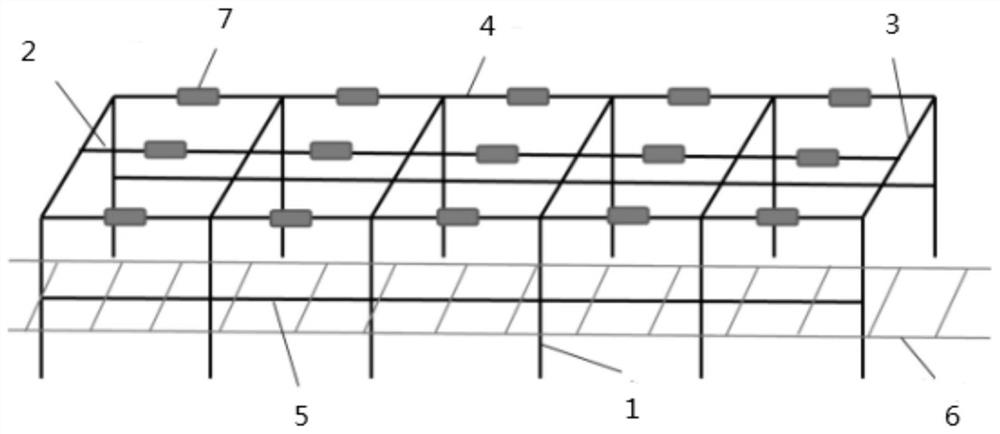

[0025] This embodiment provides a steel structure protective shed hole for high-voltage power lines and railway crossing sections, such as figure 1 As shown, the vertical support 1 is arranged on both sides of the railway 6, and the beam 3 at the top of the support column 1 and the support column 1 form a door frame unit, and the longitudinal beams 2 perpendicular to the beam 3 are arranged between adjacent units, and the connection Buffers 7 are provided on the side beams 5 , longitudinal beams or cross beams adjacent to the support column 1 .

[0026] All the structural units of the shed-cave system are made of steel structure, and the rods of the shed-cave system are connected by bolts. The whole shed is spliced and installed by bolts. When the wire falls due to a fault, the buffer member 7 can greatly reduce the impact force of the wire on the shed hole.

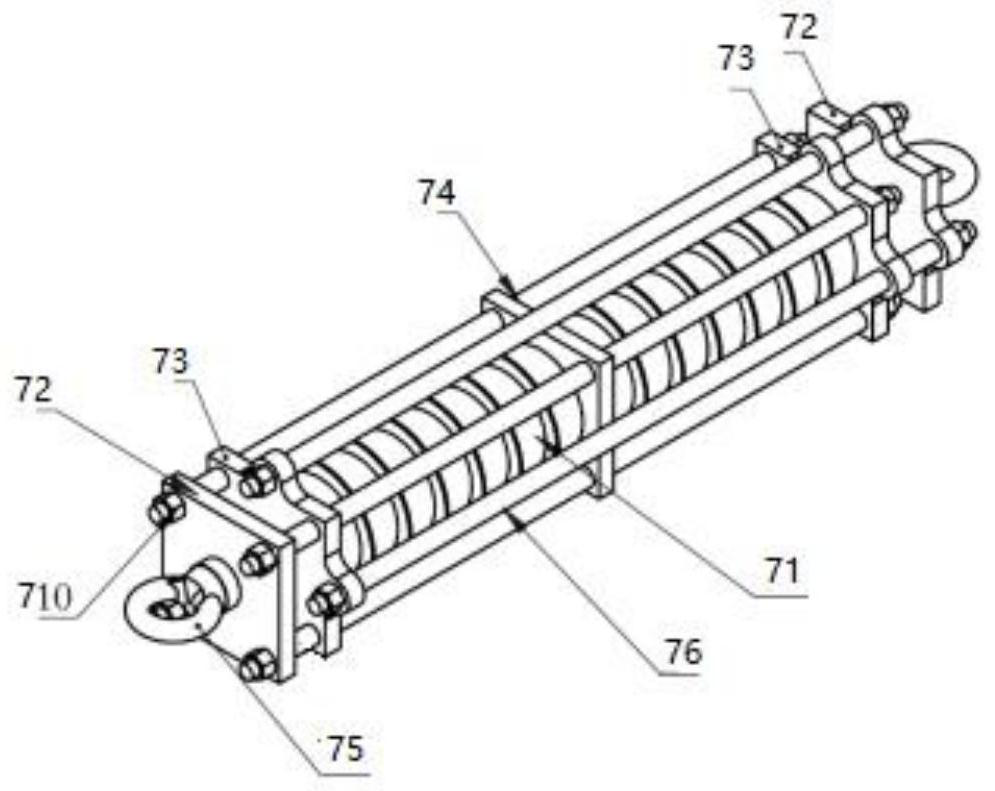

[0027] Such as figure 2 As shown, the buffer member 7 is elongated, and is provided with connecting rods 76 arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com