Cover clamping device of glue binding machine

A clamping device, glue binding machine technology, applied in book binding, adhesive for binding, sustainable manufacturing/processing, etc., can solve problems such as high scrap rate, high cost, alignment error, etc. Experience, the effect of improving the sense of luxury and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

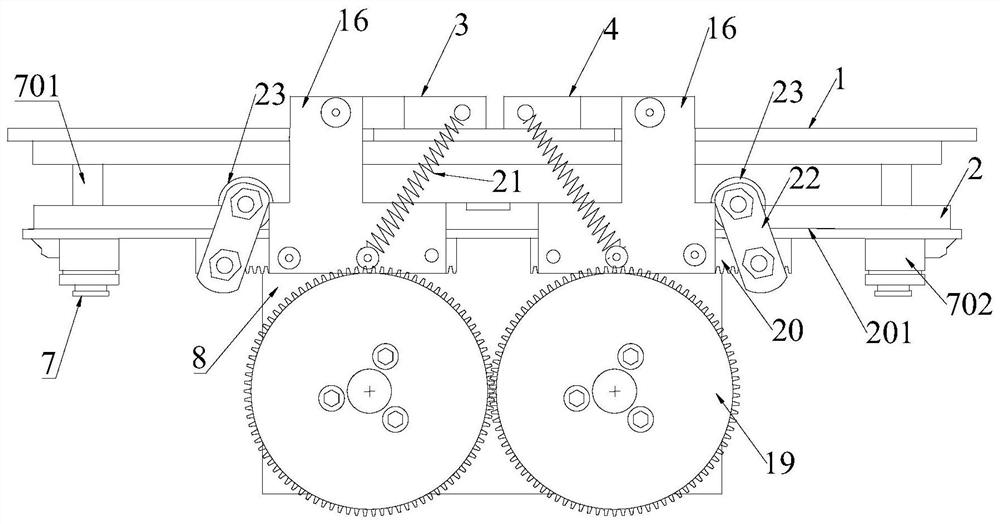

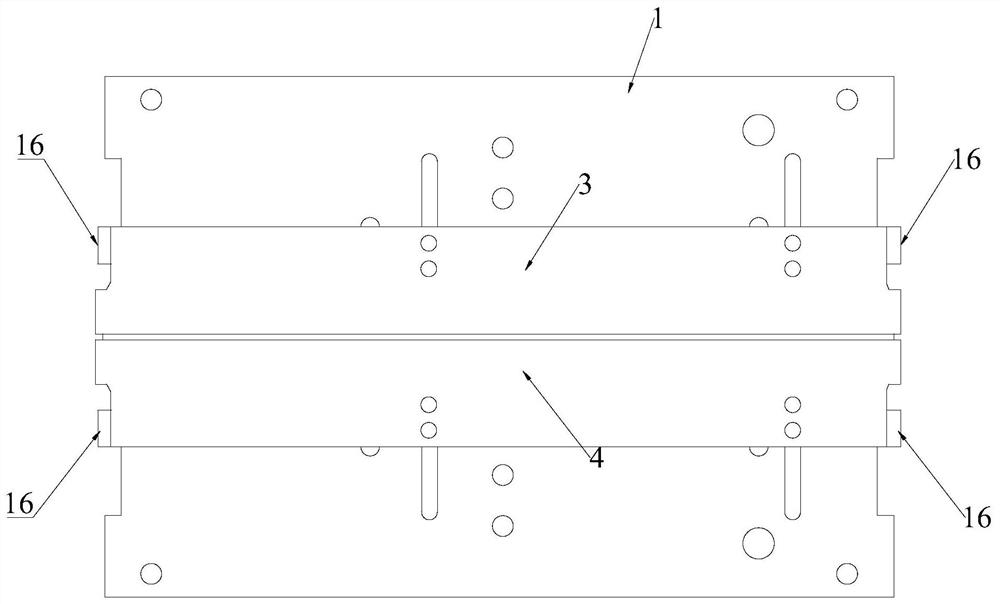

[0055] Such as figure 1 , Figure 8 As shown, the cover clamping device of the glue binding machine in this embodiment includes a first bottom plate 1, a second bottom plate 2, a first shaping block 3, a second shaping block 4, a clamping motor 5 and a clamping motor transmission structure , lifting motor 6 and lifting motor transmission structure. Wherein, the first base plate 1 is located above the second base plate 2 , and the first shaped block 3 and the second shaped block 4 are located above the first base plate 1 .

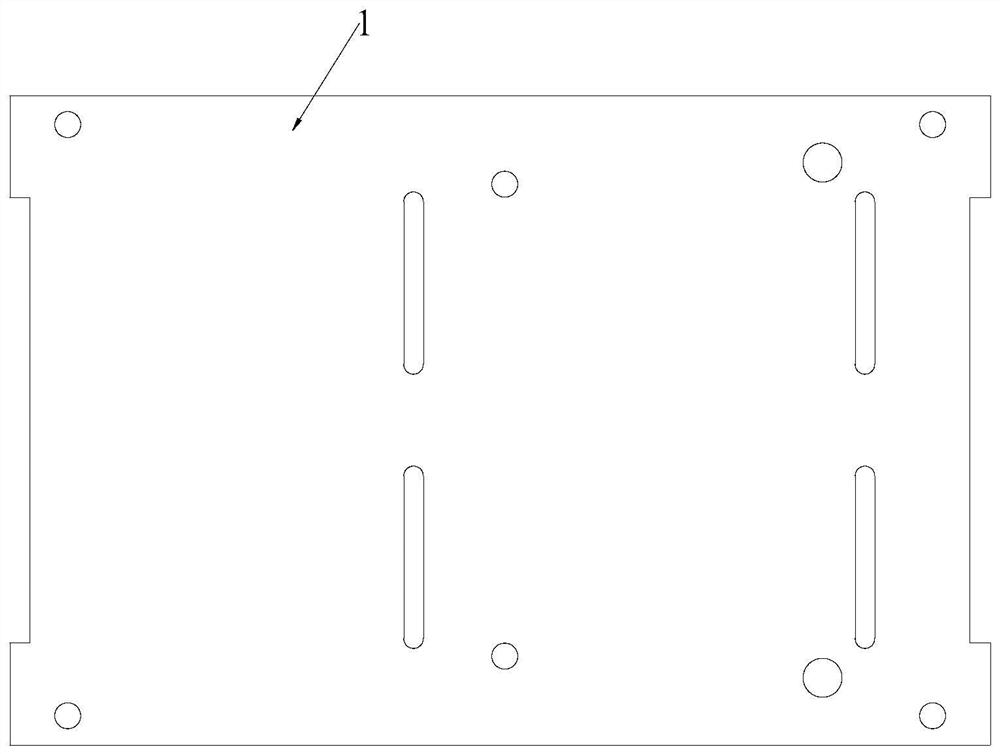

[0056] In this example, see image 3 with Figure 4 , the first bottom plate 1 is a rectangular plate structure, and the second bottom plate 2 is a rectangular frame structure, that is, the second bottom plate 2 is a hollow structure in the middle. The position of the first base plate 1 is fixed, and the first base plate 1 is connected to the second base plate 2 through four lift positioning shafts 7 , which are located at four corners below the first b...

specific Embodiment 2

[0071] When only one side of the cover needs to be indented, one of the shaping blocks, in this embodiment, the second shaping block is fixedly connected to the first bottom plate, and the second shaping block is no longer provided with movable connecting rods and corresponding gears. rack structure. It is only necessary to set the movable connecting rod and the corresponding rack and pinion structure on the first sizing block, wherein the first sizing block, the movable connecting rod and the corresponding rack and pinion structure, the first sizing block and the movable connecting rod The connection structure is the same as that in the first embodiment.

[0072]In the above-mentioned specific embodiment 1 and specific embodiment 2, the lifting of the second bottom plate is realized by a structural combination of a lifting motor, a gear, a cam, and the like. Since the first bottom plate is fixed, through the lifting of the second bottom plate, the outer end of the two shaped...

specific Embodiment 3

[0074] The cover clamping device of the glue binding machine in this embodiment includes a first bottom plate 1 and a second bottom plate 2 , and the second bottom plate is controlled to lift up and down by a liftable X-shaped support structure 24 . In this embodiment, both the first bottom plate and the second bottom plate are plate-shaped structures without hollow parts. Two support plates and a clamping motor transmission structure are arranged under the second bottom plate, and the specific structure is the same as that of the first embodiment. The bottom end of the movable connecting rod 16 is fixedly connected to the rack 20, and the top end is movably connected to the side of the outer end of the shaping plate.

[0075] Wherein, an X-shaped support structure 24 is arranged between the first base plate 1 and the second base plate 2, and the X-shaped support structure includes an upper beam fixedly installed on the bottom end of the first base plate, a lower beam fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com