Electric double-shaft simulation table assembly

A simulation table and dual-axis technology, applied in the direction of electrical testing/monitoring, instrumentation, control/regulation systems, etc., can solve the problems of lengthening the pipeline length, lowering test efficiency, time-consuming and labor-intensive, etc., to improve efficiency, reduce manual recording and Classification, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

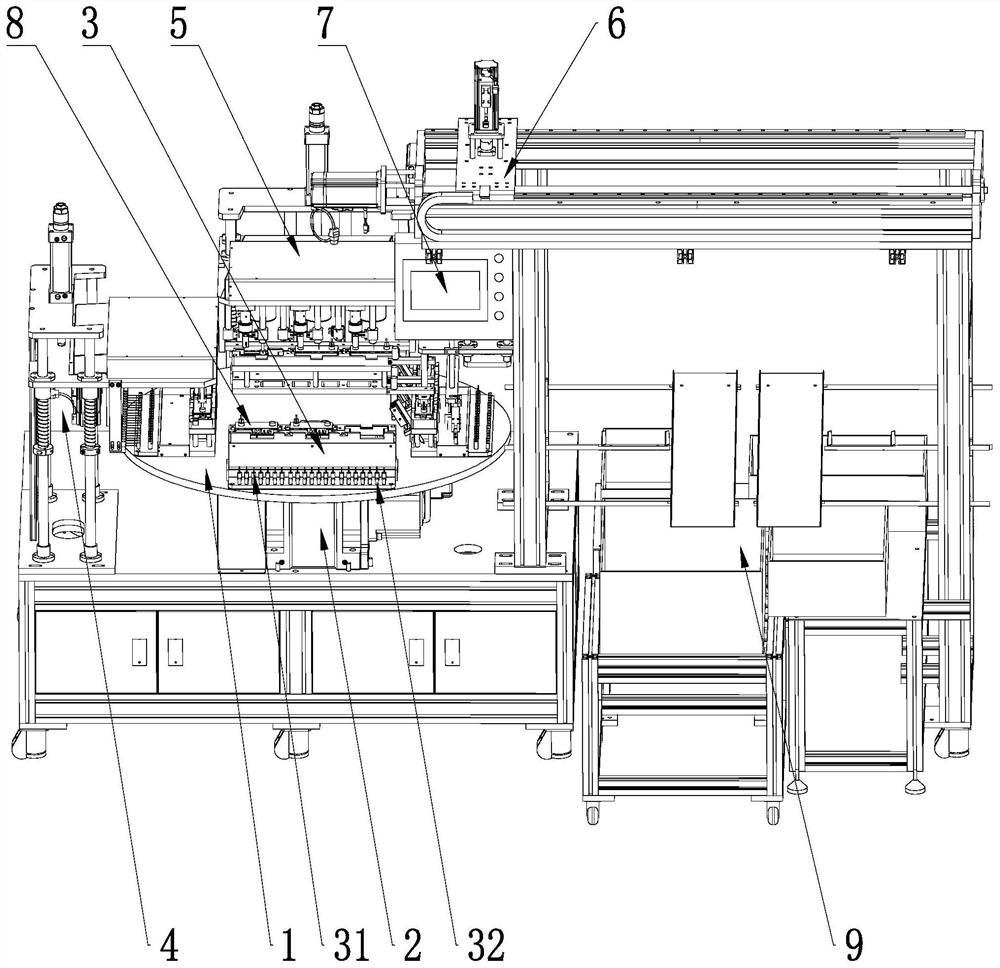

[0036] like Figure 1-10 As shown, this embodiment relates to an electric biaxial simulation table assembly, which includes a workbench 1, and a transmission device 2 for driving the workbench 1 to rotate is provided under the workbench 1;

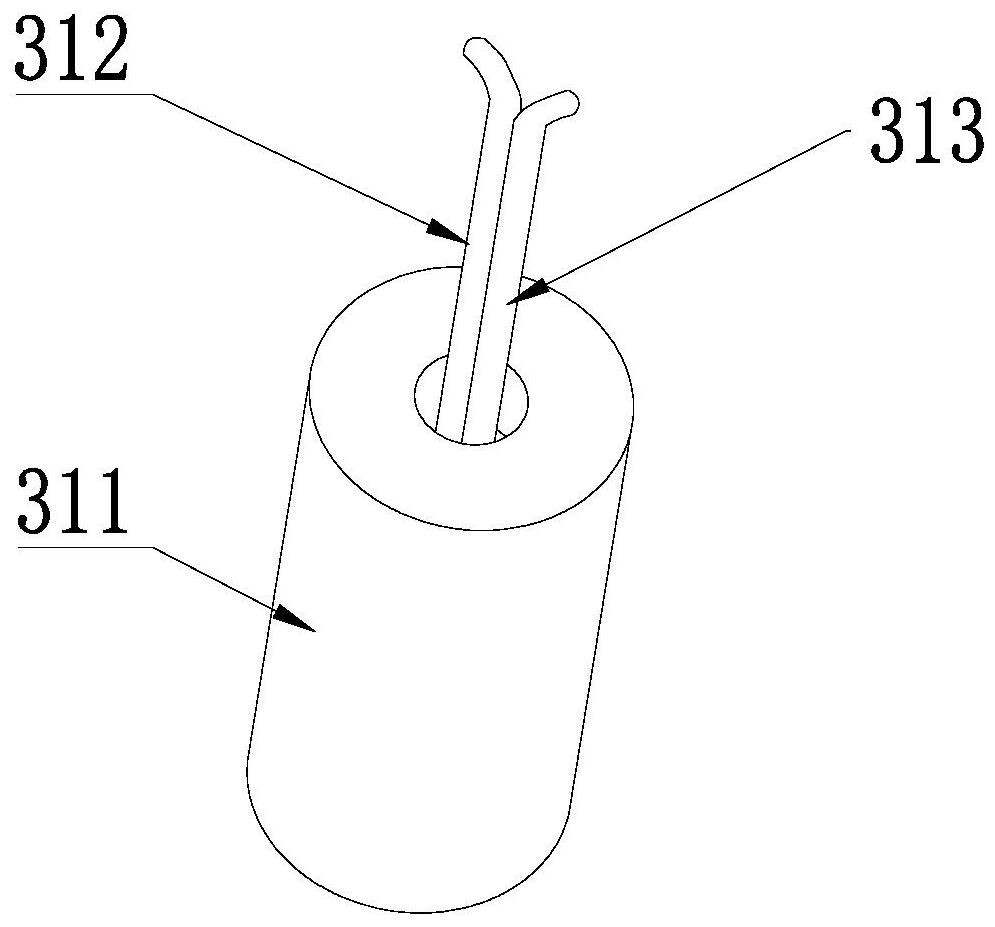

[0037] Multiple controller installation platforms 3 are used to install and fix the electric dual-axis controller 8, and multiple controller installation platforms 3 are fixed on the workbench 1;

[0038] The mode testing mechanism 4 is used to test the mode function of the electric dual-axis controller 8, and the mode testing mechanism 4 is movably connected with the controller installation platform 3;

[0039] The timing test mechanism 5 is used to test the timing function of the electric dual-axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com