Rotor end face tooth profile of high-temperature-resistant double-screw machine

A twin-screw and rotor-end technology, which is applied to components, mechanical equipment, engine components, etc. of elastic fluid pumping devices, can solve problems such as increased machine leakage, rotor seizure, and inability to continue to rotate, and achieve damage The effect is small, not easy to bloat, and small in scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The tooth profile of the rotor end surface of the twin-screw compressor of the present invention will be described in detail below with reference to the drawings and specific embodiments.

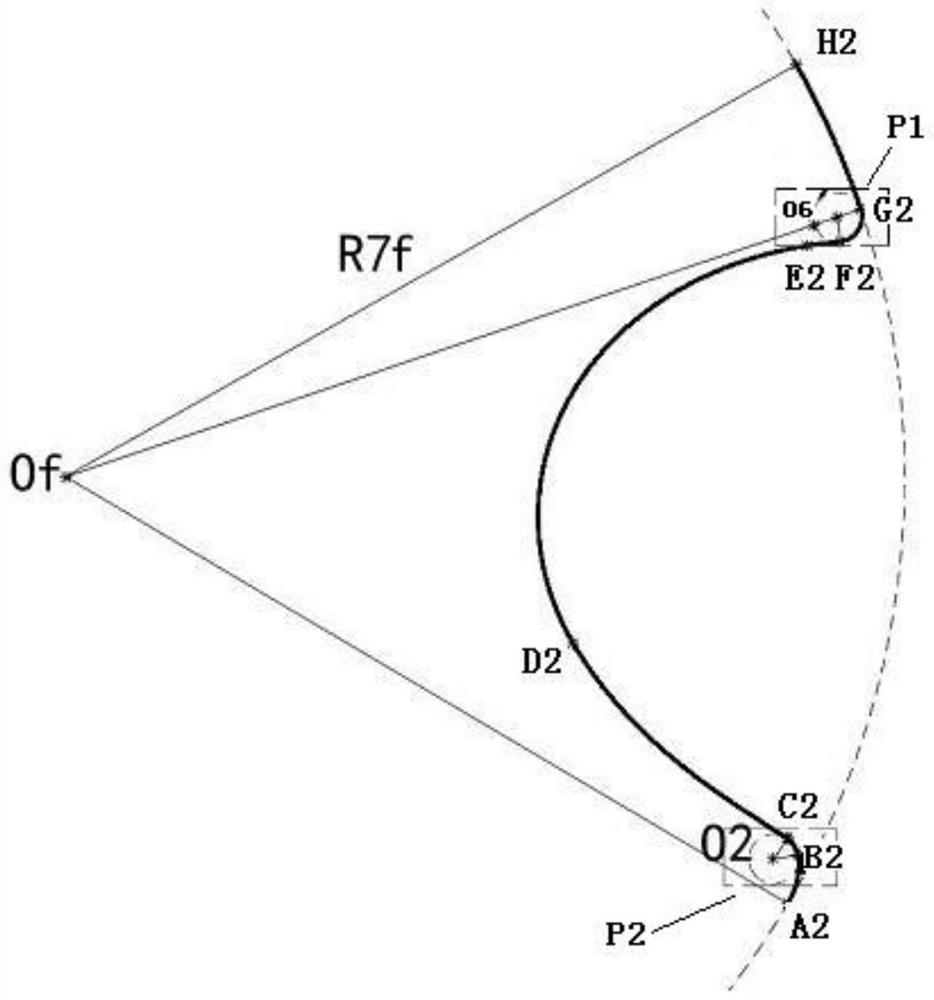

[0021] see Figure 1 to Figure 10 . A twin-screw machine according to an embodiment of the present invention includes a female rotor F and a male rotor M. The number of teeth of the female rotor F is more than that of the male rotor. The outer diameter of the female rotor F is smaller than the pitch circle diameter of the female rotor F. Each tooth profile of the end surface of the female rotor F and the end surface of the male rotor M is formed by smoothly connecting the beginning and the end of seven curves.

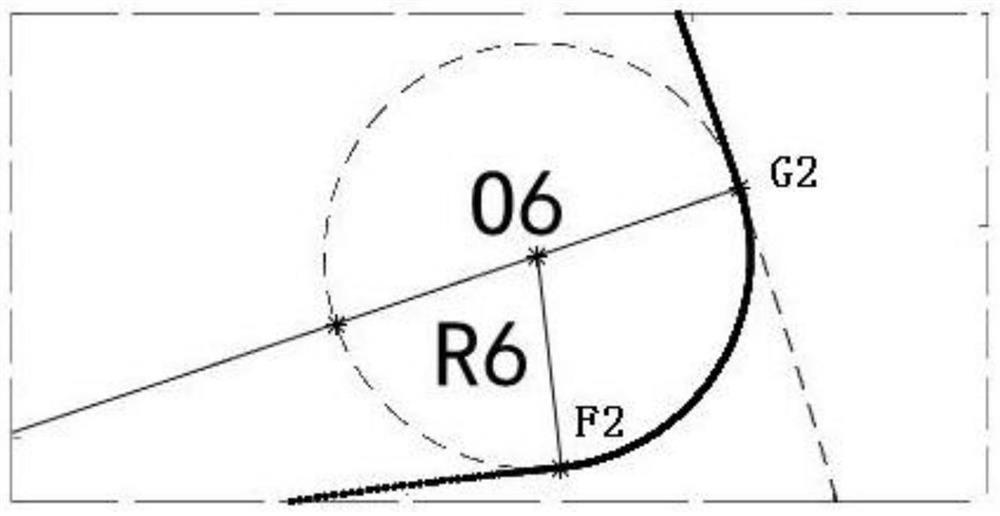

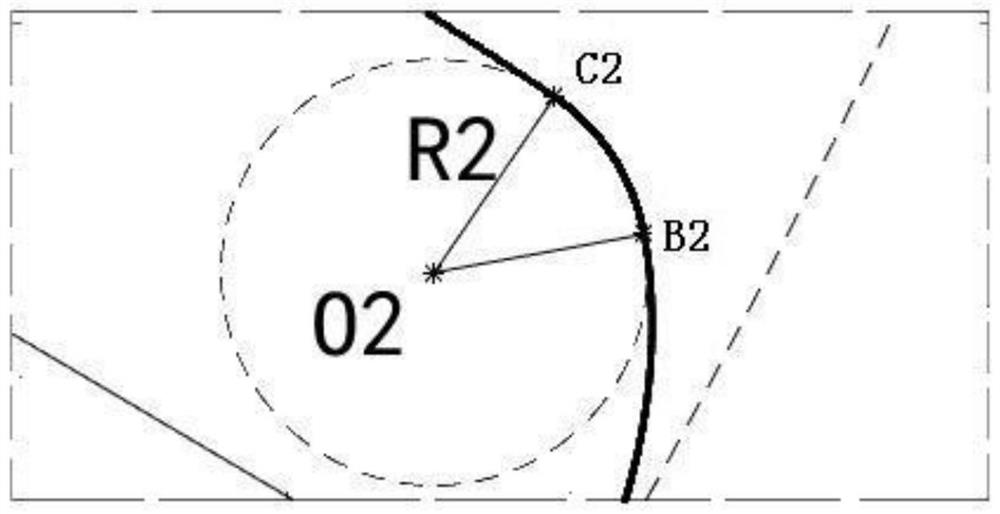

[0022] The tooth curves of each tooth type on the end face of the female rotor include the sequentially connected curve segment A2B2, arc segment B2C2, curve segment C2D2, curve segment D2E2, curve segment E2F2, arc segment F2G2 and arc segment G2H2; the curve segment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com