Dragging starting system and engineering equipment using same

A technology of starting system and sliding gear, which can be used in starting devices with fluid drive, starting devices with mechanical power storage, starting of engines, etc., which can solve the problem of high labor intensity of drivers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

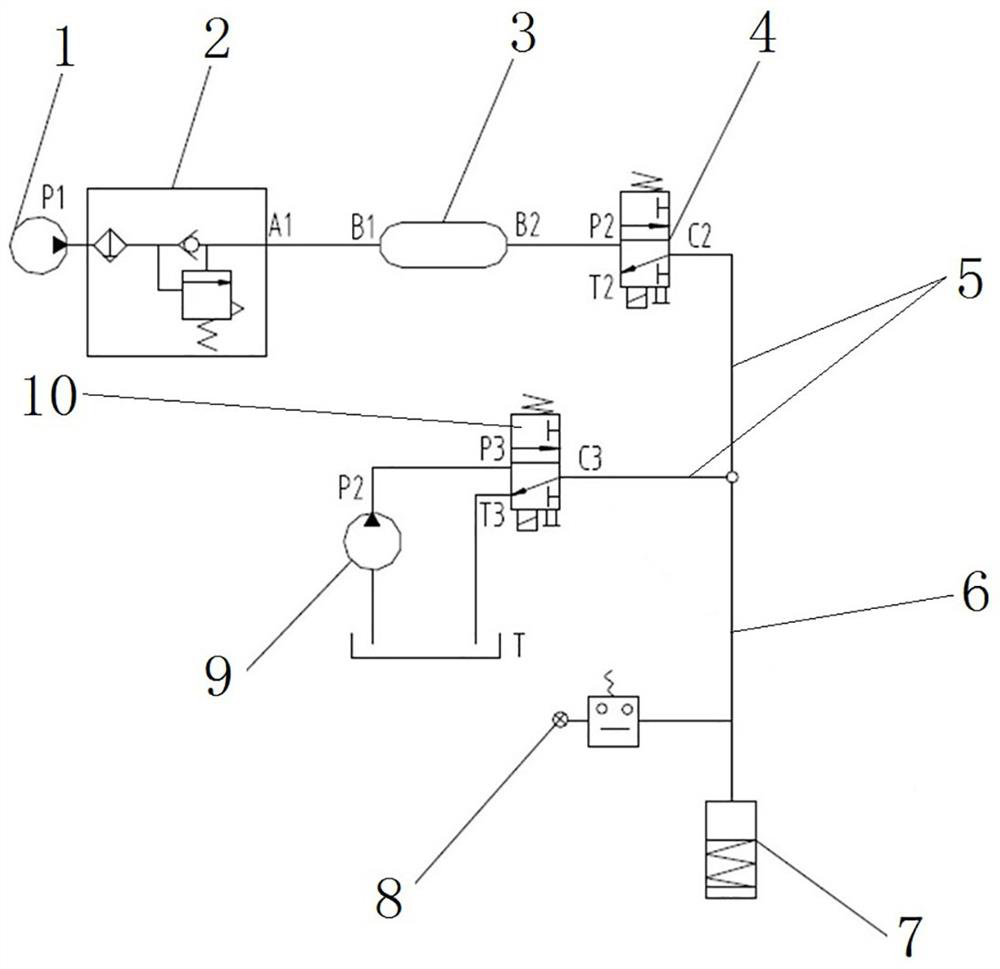

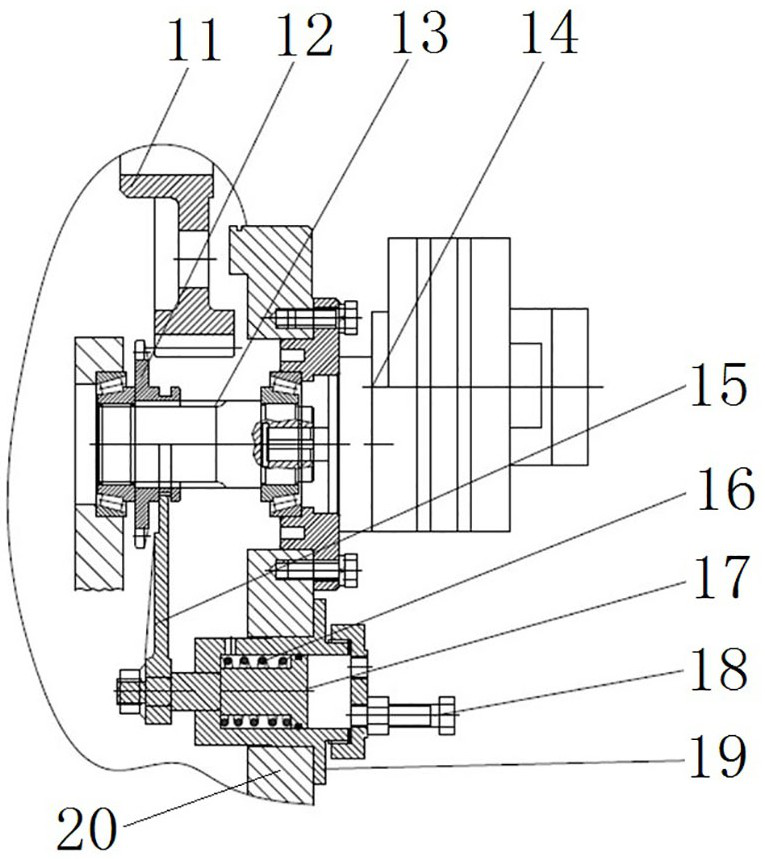

[0050] Such as figure 1 and figure 2 As shown, when the external temperature is low and the voltage of the storage battery is not enough to start the engine, the drag start system of the present invention is used to start the engine. The drag start system comprises a drag start device 7, and the structure of the drag start device 7 is as follows: figure 2 shown.

[0051] The drag starting device 7 includes an output gear 11, and the output gear 11 is fixedly installed on the output shaft of the gearbox. The drag starter 7 also includes a base 20, the base 20 is fixed on the fuselage of the engineering equipment during use, specifically can be fixed on the gearbox, the base 20 is fixedly equipped with a drag starter pump 14, and the drag starter pump 14 The input shaft 13 is axially slidably provided with a sliding gear 12 , and on the circumferential direction of the input shaft 13 , the input shaft 13 and the sliding gear 12 are fixedly assembled. In order to realize th...

Embodiment 1

[0063] In Embodiment 1, the fluid power source includes an air compressor and a hydraulic pump. In this embodiment, only one of the fluid power sources is reserved.

specific Embodiment 3

[0065] In Embodiment 1, the solenoid valve has a return spring, and during normal driving, the fluid power source communicates with the piston cylinder by means of the return spring. In this embodiment, the solenoid valve has two electromagnets arranged opposite to each other. One electromagnet drives the valve core to move so that the fluid power source communicates with the piston cylinder, and the other electromagnet drives the valve core to move so that the piston cylinder communicates with the pressure relief port. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com