Ultra-dry paper diaper production equipment

A technology for producing equipment and diapers, applied in the field of ultra-dry diaper production equipment, can solve the problems of difficulty in producing dry diapers, and achieve the effects of increasing spacing, improving production efficiency, and having good air permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0027] Embodiments of the invention are:

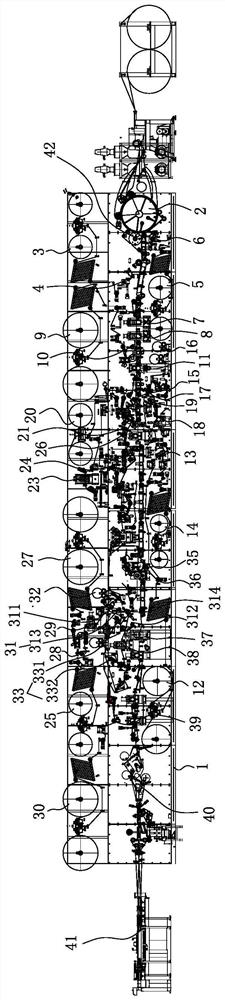

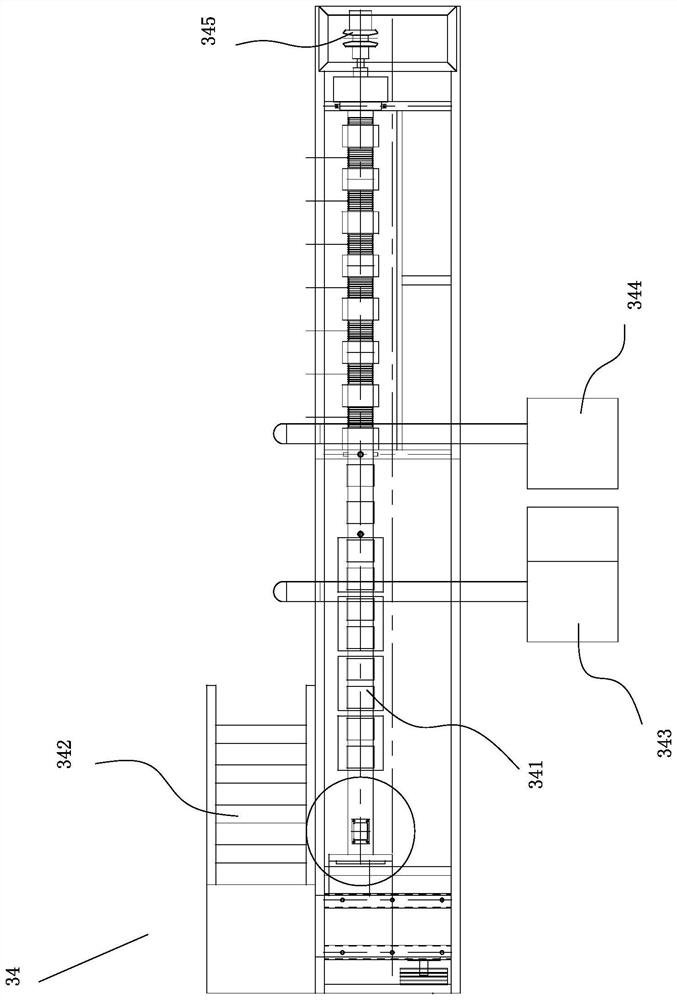

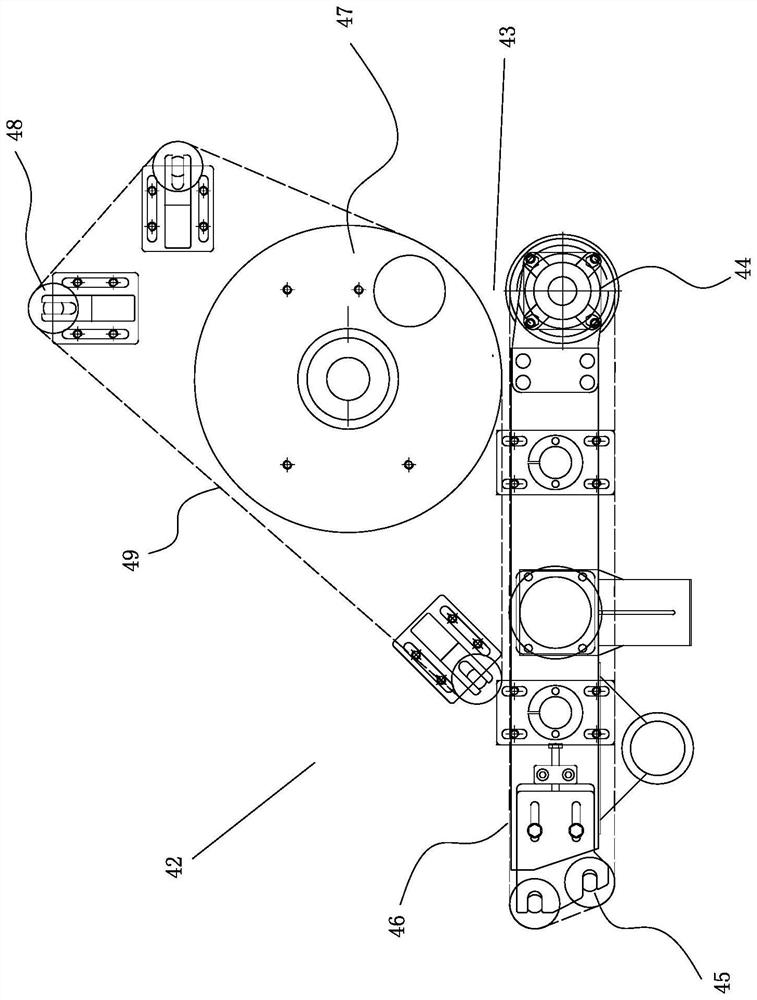

[0028] refer to figure 1 and figure 2 Said, a kind of ultra-dry diaper production equipment, comprises frame 1, the cotton core preparation assembly that is arranged on the frame, the liquid impermeable bottom layer preparation assembly, the liquid permeable surface layer preparation assembly, the foam net layer preparation assembly and Finished output components;

[0029] The cotton core preparation assembly includes a molding die wheel 2, an upper toilet paper unwinding mechanism 3, an upper toilet paper sizing mechanism 4, a lower toilet paper unwinding mechanism 5, a lower toilet paper sizing mechanism 6, a compacting mechanism 7, a grid mechanism 8, A diversion layer unwinding mechanism 9, a diversion layer sizing mechanism 10, a cotton core cutting mechanism 11, and the liquid-impermeable bottom pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com